Machine vision positioning method for automatic screw assembling

A machine vision and automatic assembly technology, applied in the direction of instruments, image data processing, image feedback, etc., can solve the problems of assembly failure, high requirements for feature point selection, low precision, etc., achieve high precision, overcome assembly failure, and shorten time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

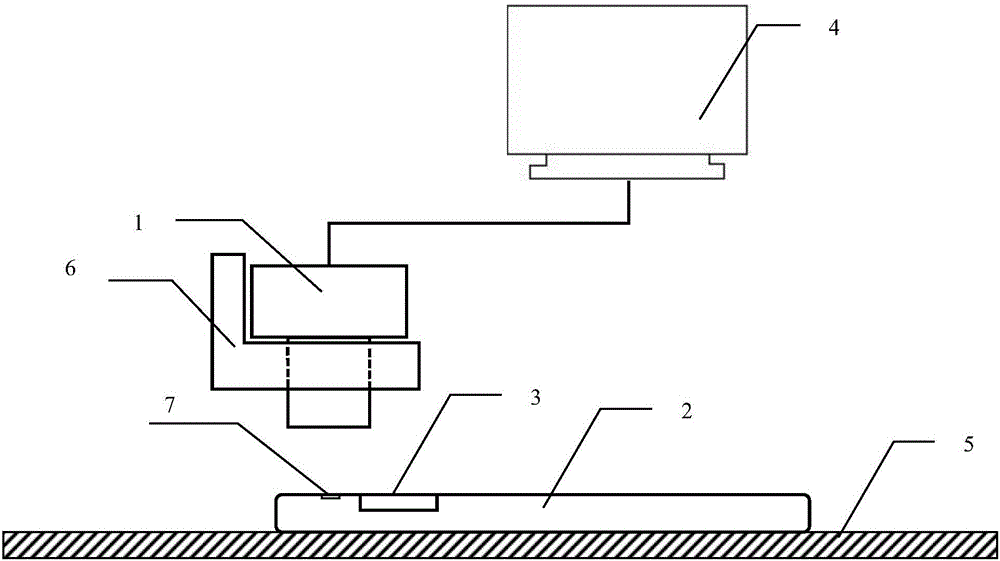

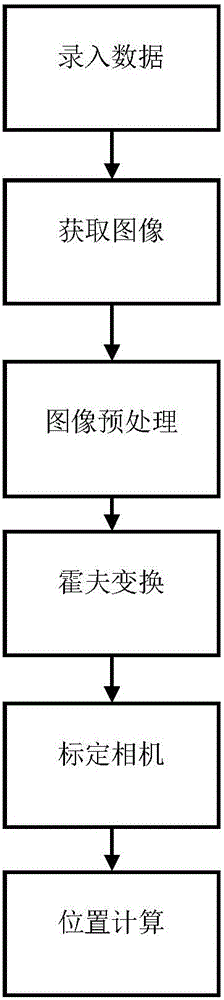

[0053] This embodiment is a machine vision positioning method for automatic assembly of screws on a TV backplane, and the implementation steps are as follows:

[0054] A. Devices involved:

[0055] The devices involved in the implementation of the machine vision positioning method for automatic screw assembly include an industrial camera 1, the product part 2 to be assembled is a TV backplane, an industrial computer 4, a workbench 5 of an automatic screw assembly device, and an industrial camera installation slot 6 ;

[0056] B. The steps are as follows:

[0057] The first step is to enter data:

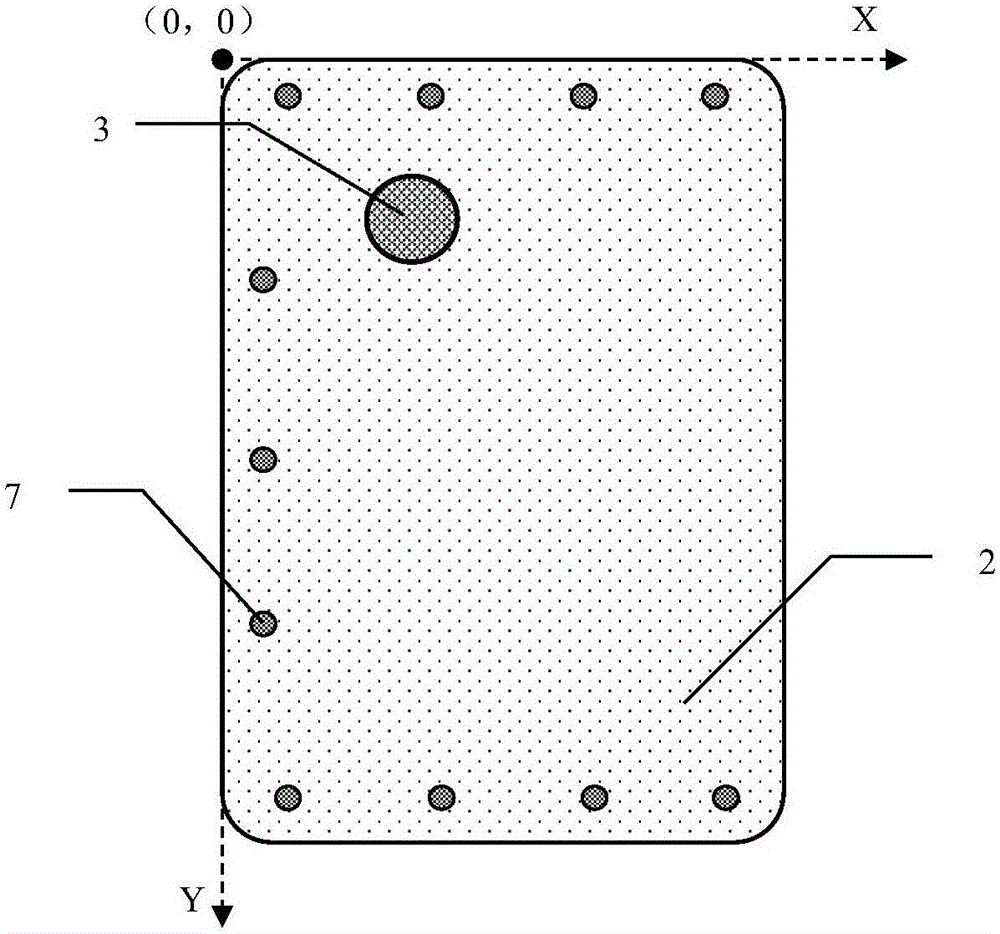

[0058] First collect the size information of the TV backplane of the product part 2 to be assembled and the distribution information of the round holes on the surface, as well as the distribution position information of each screw hole and the position of the screw hole 7 on the product part to be assembled. The contour circle is the characteristic circle 3 of the product part to ...

Embodiment 2

[0082] Except for the following parts, others are the same as Example 1:

[0083] The first step is to enter data:

[0084] First collect the size information of the TV backplane of the product part 2 to be assembled and the distribution information of the round holes on the surface, as well as the distribution position information of each screw hole and the position of the screw hole 7 on the product part to be assembled. The contour circle is the characteristic circle 3 of the product part to be assembled to be positioned, the radius of the hole and the location information of the characteristic circle 3 of the product part to be assembled to be positioned are recorded and used as the feature information of the image, and the product part to be assembled is 2. The above-mentioned relevant information of the TV backplane is entered into the measurement software of the industrial computer 4; the length of the TV backplane of the product part 2 to be assembled is 650mm, and the...

Embodiment 3

[0096] Except for the following parts, others are the same as Example 1:

[0097] The first step is to enter data:

[0098] First collect the size information of the TV backplane of the product part 2 to be assembled and the distribution information of the round holes on the surface, as well as the distribution position information of each screw hole and the position of the screw hole 7 on the product part to be assembled. The contour circle is the characteristic circle 3 of the product part to be assembled to be positioned, the radius of the hole and the location information of the characteristic circle 3 of the product part to be assembled to be positioned are recorded and used as the feature information of the image, and the product part to be assembled is 2. The above-mentioned relevant information of the TV backplane is entered into the measurement software of the industrial computer 4; the length of the TV backplane of the product part 2 to be assembled is 455mm, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com