Continuous wave magnetron waveguide excitation device

A technology of excitation device and magnetron, which is applied in the direction of magnetron, discharge tube, transit time type electron tube, etc., can solve the design requirements that cannot meet the miniaturization and miniaturization of microwave generators, and the volume of microwave generators is large, etc. problem, to achieve the effect of reducing space, reasonable structure design and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

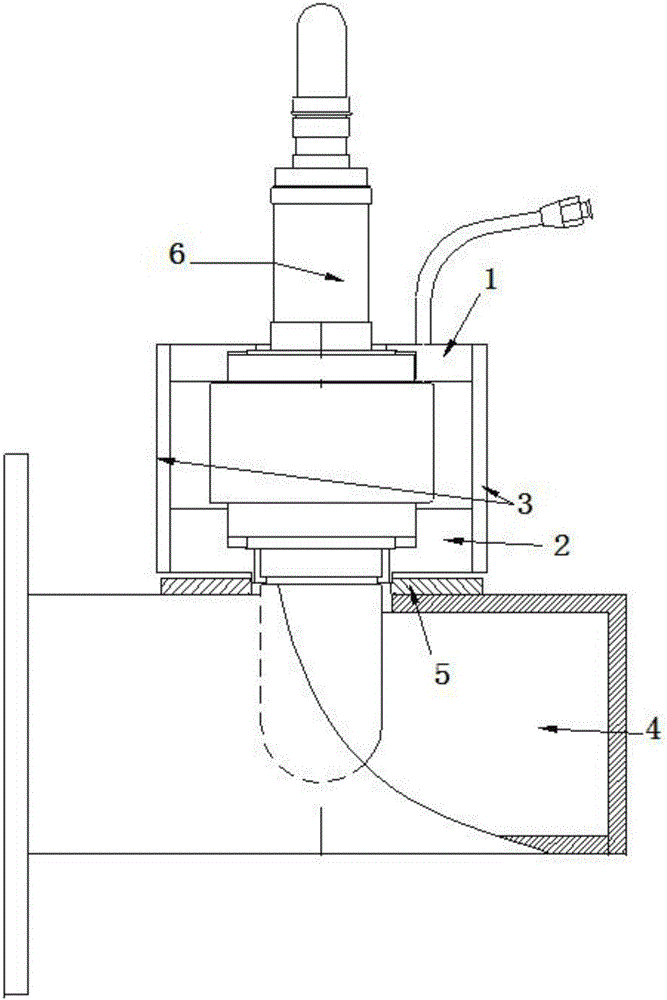

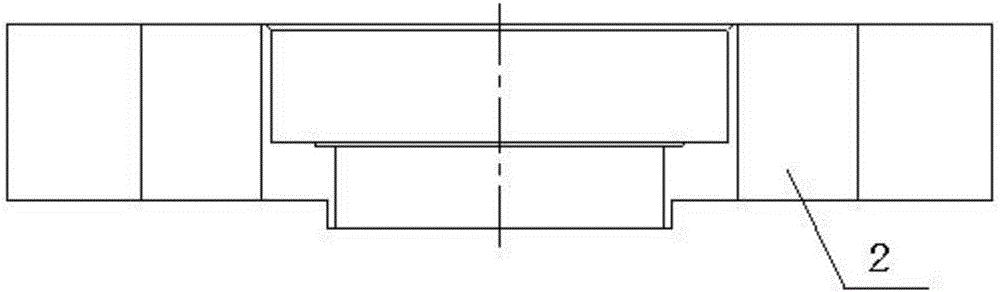

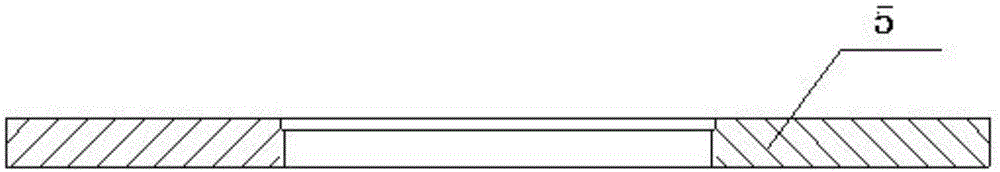

[0023] Such as Figure 1 to Figure 4 As shown, a continuous wave magnetron waveguide excitation device includes an upper magnetic circuit 1, a lower magnetic circuit 2 located below the upper magnetic circuit 1, and magnetic circuit side plates located on both sides of the upper magnetic circuit 1 and the lower magnetic circuit 2 3. The CK-147 continuous wave magnetron 6 installed in the middle of the upper magnetic circuit 1, the lower magnetic circuit 2 and the magnetic circuit side plate 3, the installation base 5 located under the lower magnetic circuit 2 and the BJ- 9 waveguide excitation cavity 4 .

[0024] In the continuous wave magnetron waveguide excitation device described above, the lower magnetic circuit 2 adopts a raised ring structure, the upper magnetic circuit 1 and the lower magnetic circuit 2 are both made of samarium-cobalt permanent magnet materials, and the magnetic circuit side plate 3 is made of pure iron material .

[0025] In the continuous wave magn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com