Wireless video remote control system of silage machine

A wireless video and silage machine technology, applied in closed-circuit television systems, signal transmission systems, televisions, etc., can solve the problems of high labor intensity and large operating errors of drivers, so as to avoid throwing waste, reduce labor intensity, and reduce The effect of operating labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

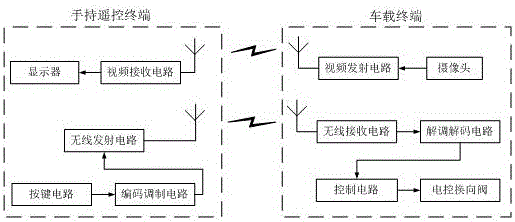

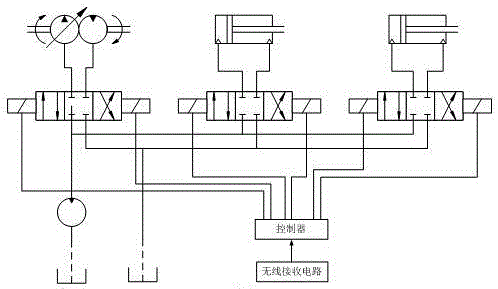

[0015] Such as figure 1 As shown, the basic principle of the wireless video remote control system of the green storage machine can be briefly described as follows:

[0016] 1. After the green storage machine is powered on, the wireless camera installed on the spray pipe will record the position image of the spray pipe;

[0017] 2. The position image of the spray pipe is sent to the video receiving circuit of the handheld terminal through the radio frequency transmitting circuit;

[0018] 3. The handheld terminal video receiving circuit transmits the image to the display;

[0019] 4. The remote operator operates the buttons on the operation panel of the handheld terminal in a targeted manner according to the image displayed on the monitor;

[0020] 5. The key commands on the operation panel are modulated by the coding modulation circuit, and then sent out through the wireless transmission circuit;

[0021] 6. After the wireless receiving short circuit of the vehicle end rece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com