Bearing steel having improved fatigue durability and method of manufacturing the same

A technology of bearing steel and bearings, applied in the direction of manufacturing tools, furnace types, quenching agents, etc., can solve problems such as durability problems, surface damage, pin wear of pinion shafts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

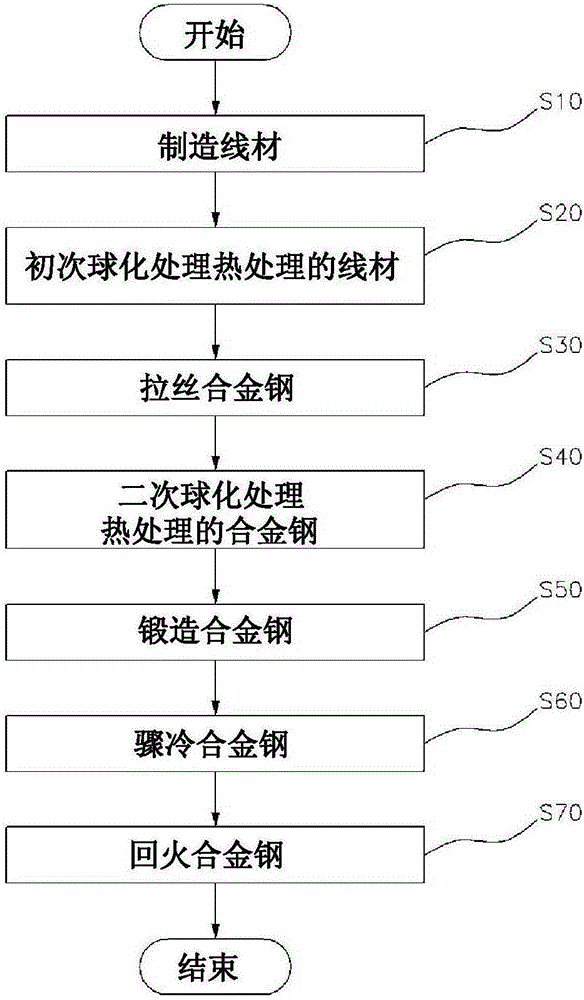

Method used

Image

Examples

Embodiment

[0095] EXAMPLES Hereinafter, the present invention will be described in more detail through examples.

[0096] These examples are only for illustrating the present invention, and it is obvious to those skilled in the art that the scope of the present invention should not be construed as being limited to these examples.

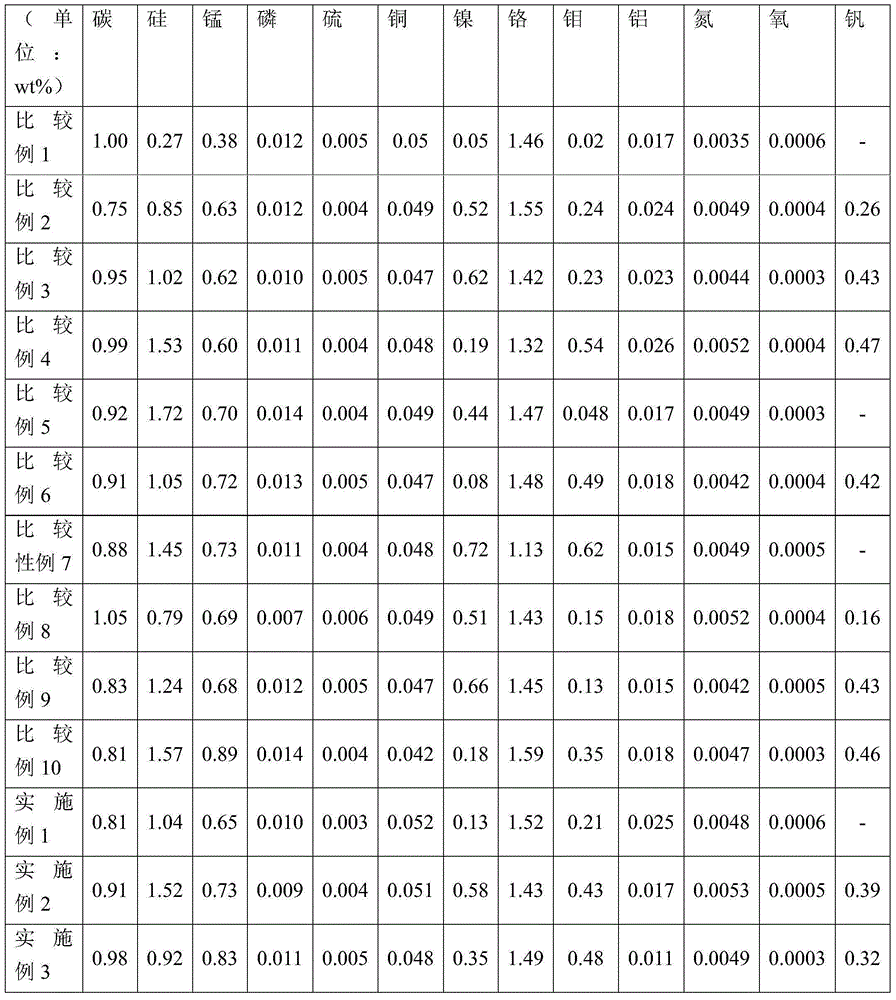

[0097] According to an exemplary embodiment of the present invention, in order to compare the physical properties of bearing steels having improved fatigue durability, comparative examples and examples having the composition described in Table 1 below were prepared.

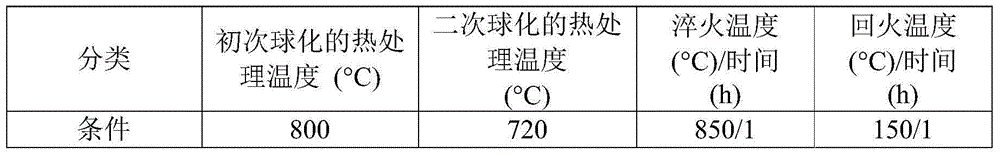

[0098] Heat treatment temperature for primary and secondary spheroidization, quenching temperature and time, and applied tempering temperature

[0099] and time conditions are shown in Table 2 below.

[0100] [Table 1]

[0101]

[0102]Table 1 shows the composition and content of Comparative Examples 1 to 10 of the bearing steel according to the prior art, and the composition and content of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com