Automatic heat power calibration method of combustion gas-type cooking system

A calibration method and a gas-fired technology, applied in heating fuels, gaseous heating fuels, household heating, etc., can solve the problems of inaccurate fire control, complex structure, and difficulty in accurately obtaining typical heating objects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

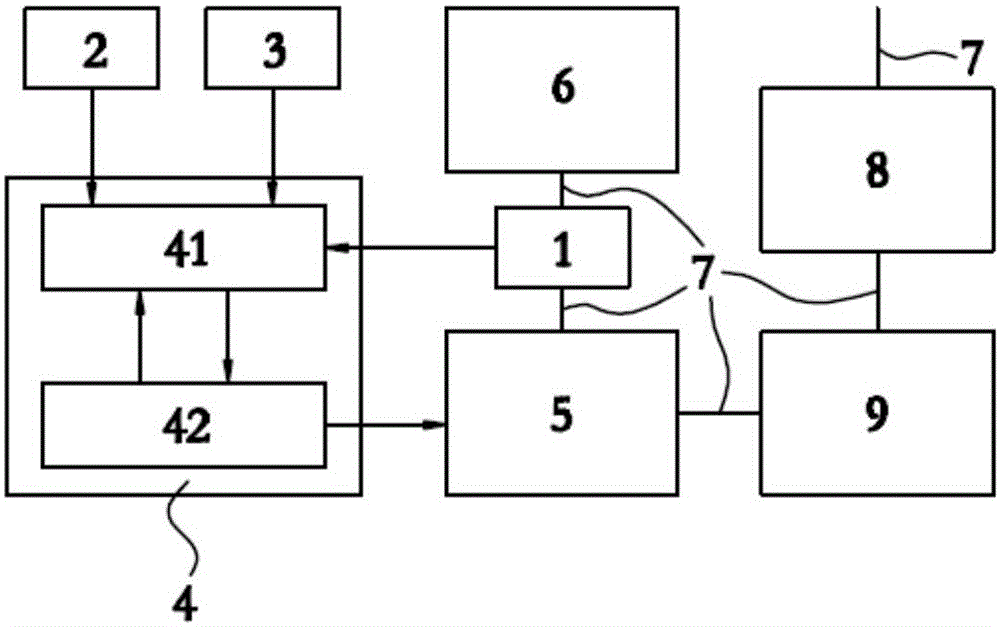

[0110] figure 1 It is a structural block diagram of Embodiment 1 of the gas cooking system with automatic fire power calibration function of the present invention. Among them, 1 represents the gas pressure detection unit, 2 represents the atmospheric pressure detection unit, 3 represents the ambient temperature detection unit, 4 represents the control processor, 41 represents the storage unit, 42 represents the processing unit, 5 represents the gas regulating device, and 6 represents the gas heating device , 7 represents a gas pipeline, 8 represents a gas flow meter, and 9 represents a gas flow velocity detection unit.

[0111] The gas pressure detection unit 1 includes a gas pressure sensor and a gas pressure detection and conversion circuit. The atmospheric pressure detection unit 2 includes an atmospheric pressure sensor and an atmospheric pressure detection and conversion circuit. The ambient temperature detection unit 3 includes an ambient temperature sensor and an ambien...

Embodiment 2

[0148] Figure 5 It is a structural block diagram of Embodiment 2 of the gas cooking system with automatic fire power calibration function of the present invention. Among them, 1 represents the gas pressure detection unit, 23 represents the ambient temperature and atmospheric pressure detection unit, 4 represents the control processor, 5 represents the gas regulating device, 6 represents the gas heating device, 7 represents the gas pipeline, 8 represents the gas flow meter, 9 represents Gas flow rate detection unit.

[0149] The gas pressure detection unit 1 includes an integrated gas pressure sensor and a gas pressure detection and conversion circuit. The ambient temperature and atmospheric pressure detection unit 23 includes an integrated ambient temperature and atmospheric pressure sensor and a corresponding detection and conversion circuit. The ambient temperature The detection unit 3 includes an integrated ambient temperature sensor and an ambient temperature detection a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com