Snow boots with all-bearing coating and waterproof effects and production technology thereof

A kind of snow boots, all-round technology, applied in the direction of boot legs, other household appliances, soles, etc., can solve the problems of poor environmental protection, difficult to achieve good foot wrapping, reduce weight, reduce thickness, and improve processing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

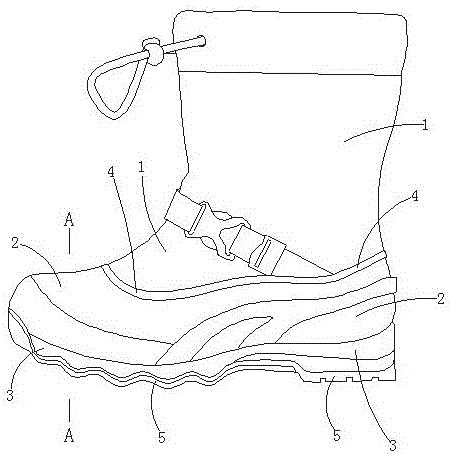

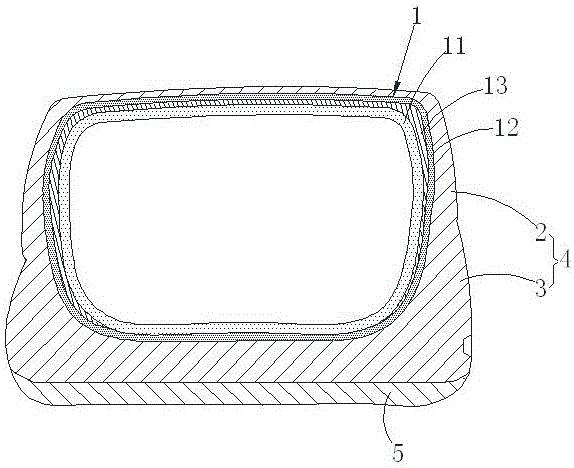

[0034] refer to figure 1 , figure 2 , all-round wrapped, waterproof snow boots, including a boot upper 1, a shoe shell 2 and a sole 3, the shoe shell 2 and the sole 3 are integrally connected, and the shoe shell 2 covers the surface of the boot upper 1. The boot upper 1 is composed of an inner boot 11 and an upper 12. The upper 12 is a waterproof and anti-siphon upper 12. The inner boot 11 is a thicker sock structure. , shock absorption and other filling materials 13. The PU bridging layer 4 is formed by injection molding of the shoe shell 2 and the sole 3 at one time. The bottom surface of the shoe sole 3 is provided with a rubber bottom sheet 5 , and the boot upper 1 and the bottom sheet 5 are connected as a whole through the PU bridging layer 4 .

[0035] More specifically, continue to refer to figure 1 , figure 2 , the manufacturing process of the all-round wrapping and waterproof snow boots: first make the boot upper 1 according to the traditional process; On the i...

Embodiment approach 2

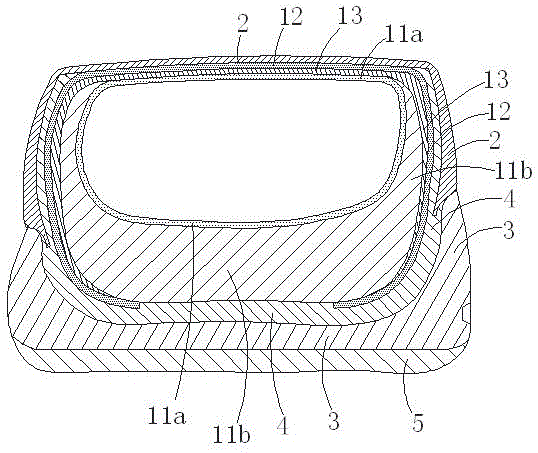

[0037] refer to figure 1 , image 3 , all-round wrapped, waterproof snow boots, including a boot upper 1, a shoe shell 2 and a sole 3, the shoe shell 2 and the sole 3 are integrally connected, and the shoe shell 2 covers the surface of the boot upper 1. refer to figure 1 , Figure 6 The boot upper 1 is composed of an inner boot 11 and an upper 12, the upper 12 is a waterproof and anti-siphon upper 12, and the inner boot 11 and the upper 12 can be filled with filling materials such as cold protection and shock absorption. The boot upper 1 is integrally connected with the above-mentioned shoe sole 3 and the above-mentioned shoe shell 2 through a PU bridging layer 4 , the shoe sole 3 is made of EVA material, and the bottom of the shoe sole 3 is fixedly connected with a rubber bottom sheet 5 .

[0038] refer to image 3 , Figure 4 , Figure 5 , the above-mentioned inner boot 11 is composed of an inner lining 11a and an injection-molded inner pad 11b, the inner lining 11a an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com