Conical sharp blade slip screw extractor with pressing device

A technology of extractor and cutter head, applied in the direction of fixator, etc., can solve the problems of easy slippage, high failure rate, screw slipping, etc., to achieve the effect of no metal scraps, no bone damage, and not easy to slip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

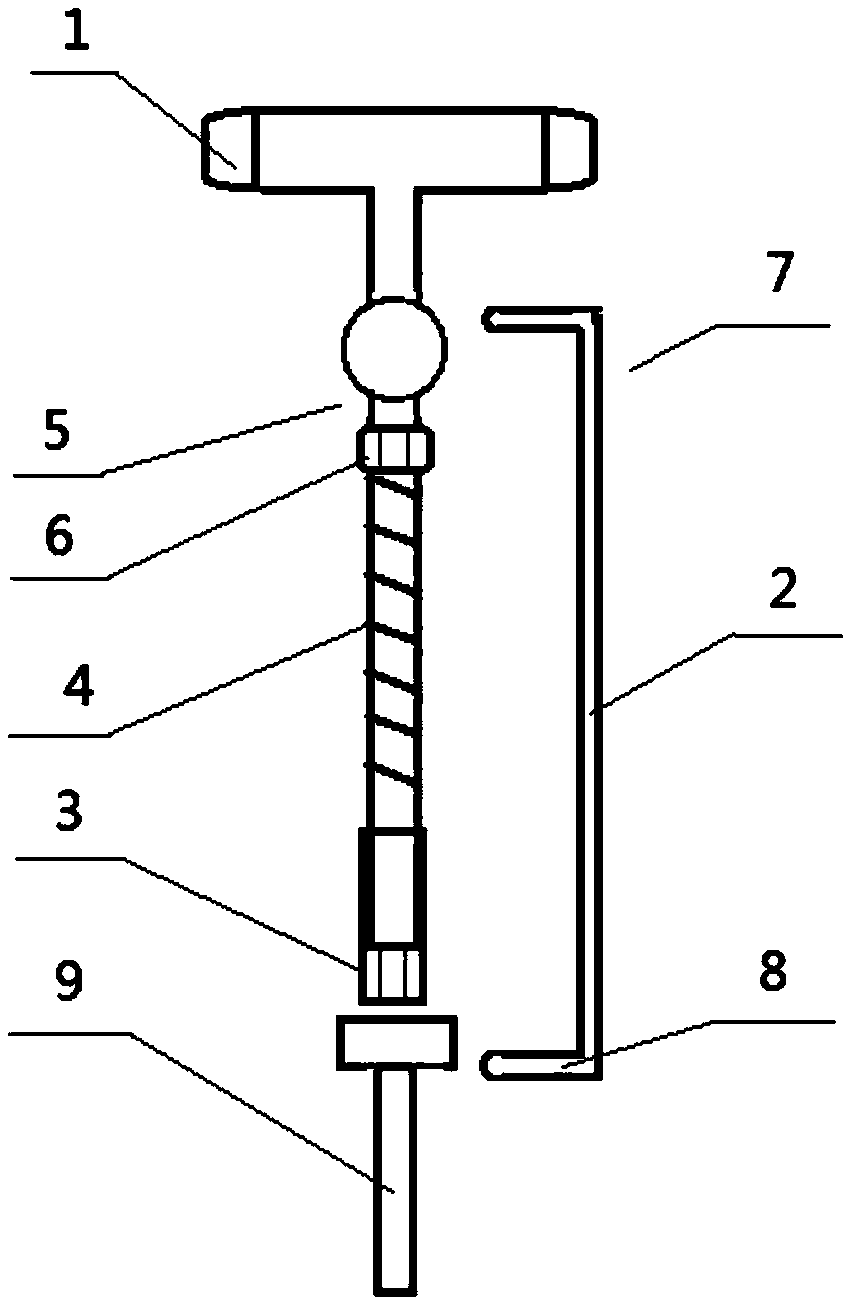

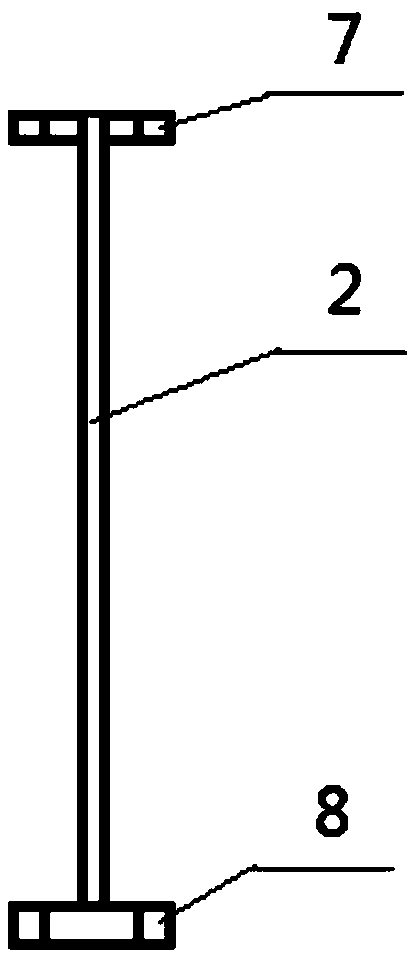

[0013] like Figure 1-2 Shown: a tapered sharp blade slide screw extractor with a pressing device, including a T-shaped handle 1 and a pressing clip 2.

[0014] The T-shaped handle 1 includes a horizontal hand handle and a longitudinal handle bar, which are connected in a T shape; the front end of the T-shaped handle 1 is connected with a tapered sharp knife head 3, and the T-shaped handle 1 is also provided with a spherical nut 5 and a hexagonal Nut 6; T-shaped handle 1 longitudinal shank is provided with thread 4, spherical nut 5 is arranged on the upper end of thread 4, and the lower end of spherical nut 5 is just above thread 4, and is fixed by thread 4 relative to T-shaped handle 1. Position; the hex nut 6 is fixed on the thread 4, wherein the hex nut 6 is a female thread, the thread 4 is a male thread, and the hex nut 6 can move up and down along the thread 4.

[0015] The center of the spherical nut 5 is provided with a through hole whose size matches the diameter of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com