A gas-liquid dispersion stirring device

The technology of a stirring device and agitator, which is applied to mixers with rotary stirring devices, transportation and packaging, mixers, etc., can solve the problems of low power consumption, unsatisfactory mixing performance and dispersion efficiency, and achieve enhanced gas holding performance. , Reduce cavitation and improve the effect of gas flooding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Embodiment 1: stirring device

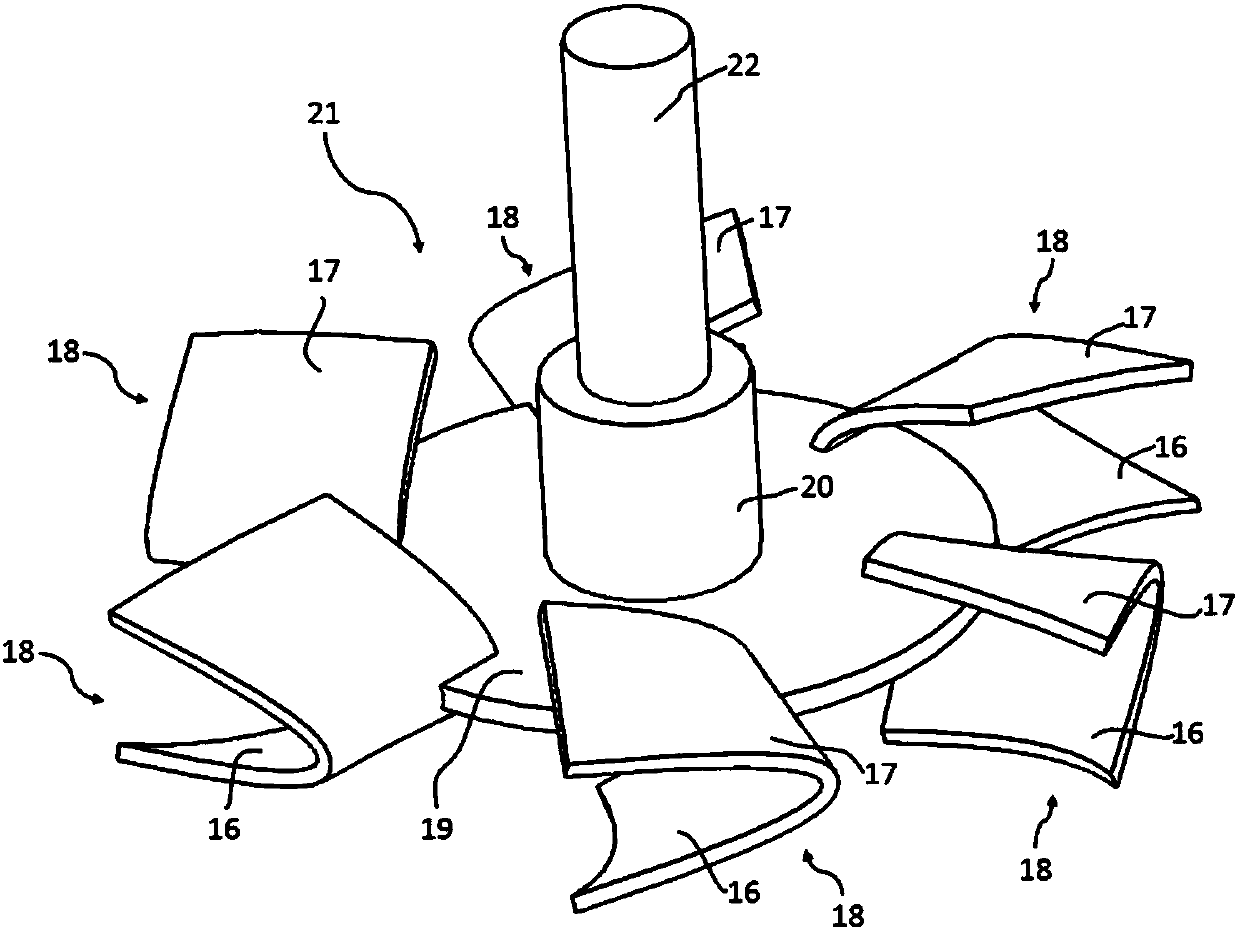

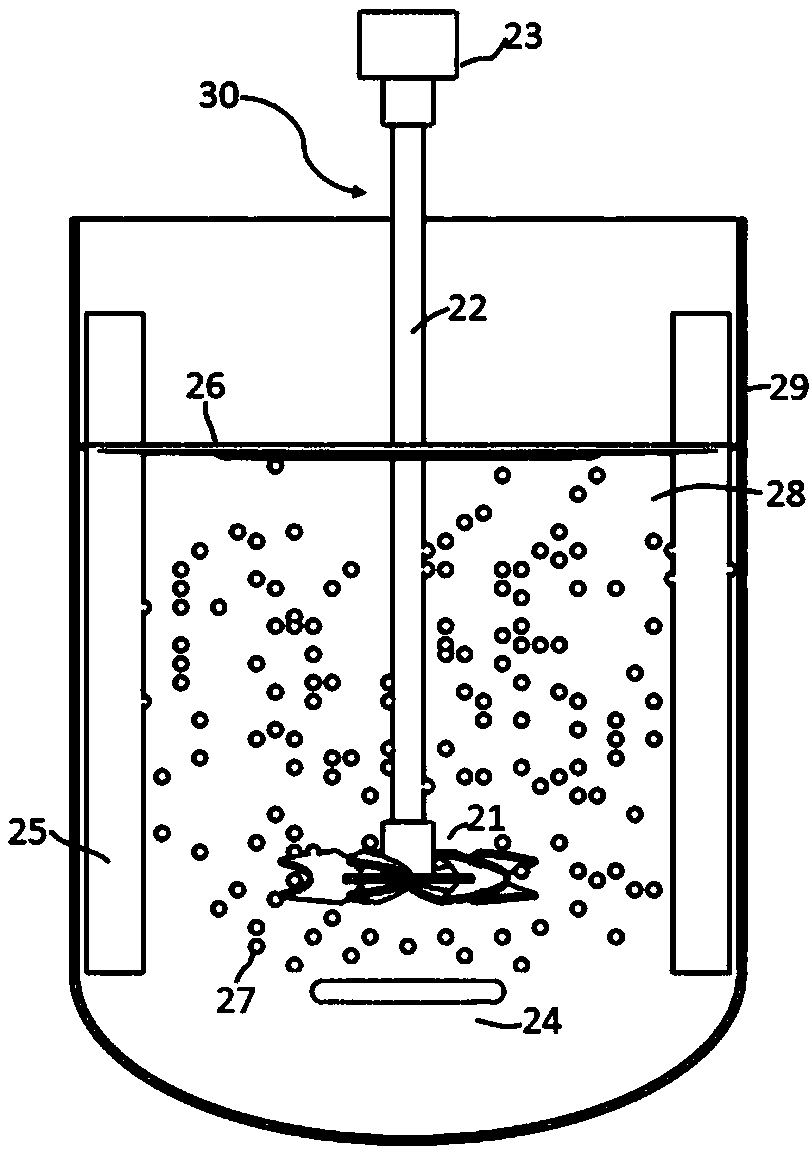

[0050] Such as figure 1 , figure 2 and Figure 6 Shown, the agitator (30) involved in the present invention comprises an agitator (21), an agitator shaft (22) and a set of power unit (23), wherein the agitator (21) comprises a disc (19) , a hub (20) and several radially extending blades (18).

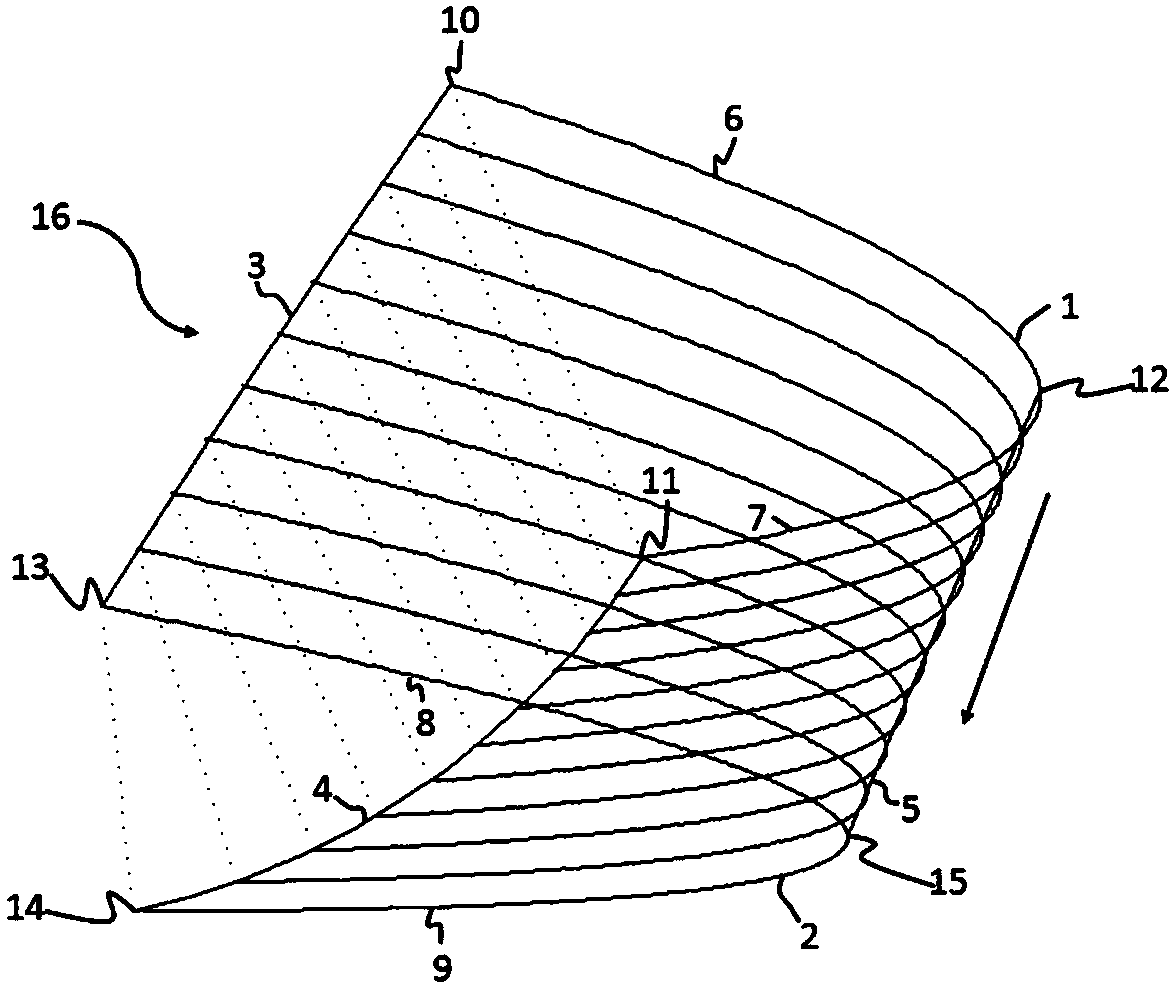

[0051] The blade (18) is obtained by increasing a certain thickness backward from the liquid-facing surface (16), and the blade (18) is obtained after thickening, and the back liquid surface (17) is obtained.

[0052] The axial section of blade (18) is V font, and the inner contour line of V font is called section line, and its shape can be parabola, hyperbola, ellipse arc and arc line etc., is good with parabola.

[0053] Such as image 3 and Figure 4 As shown, the horizontal plane where the center of the disk is located As the boundary, the section line can be divided into upper and lower parts. The intersection point of the upper and ...

Embodiment 2

[0072] Embodiment 2: the application of stirring device

[0073] The best agitating device of the embodiment of the present invention 1 is compared with traditional BT-6 type agitator, compares and carries out in the agitating tank that has standard ellipse head, and agitating tank diameter is 175mm, cylinder height 415mm, liquid volume 34L, the diameter of the stirrer is 60mm, and the stirring speed is 300r / min. The results show that the radial displacement of the stirring device of the present invention is 92% of that of the BT-6 type agitator, while the power consumption is 75% of that of the BT-6 type agitator, and the liquid discharge efficiency is 1.22 times of that of the BT-6 type agitator .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com