Automatic cleaning machine for sluice gate guide rails of frame-type PX pump station

A sluice gate and frame-type technology, which is applied in the field of automatic cleaning machine for sluice gate guide rails of frame-type PX pumping stations, can solve the problems of laborious, dangerous, time-consuming, etc., and achieve the effect of facilitating production and manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

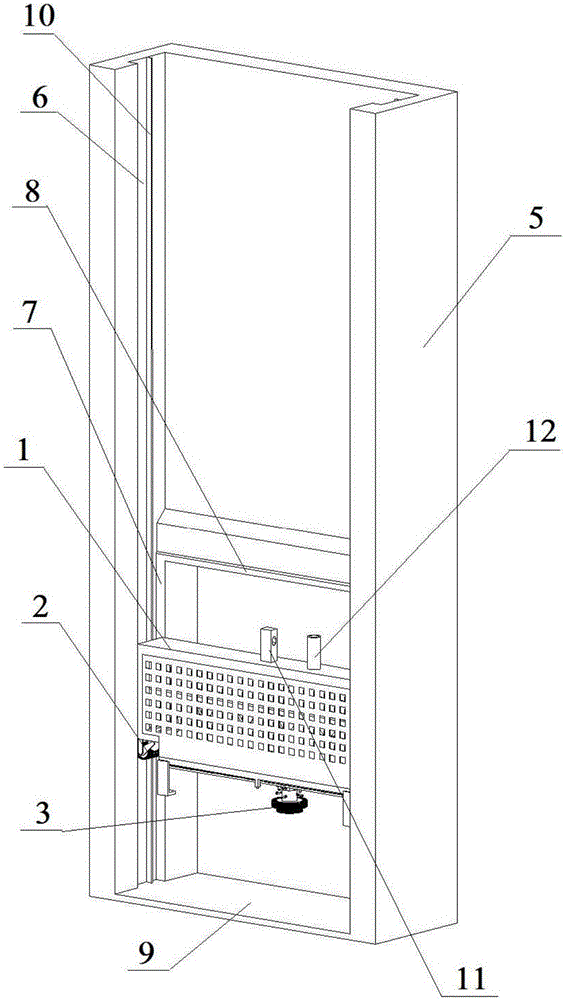

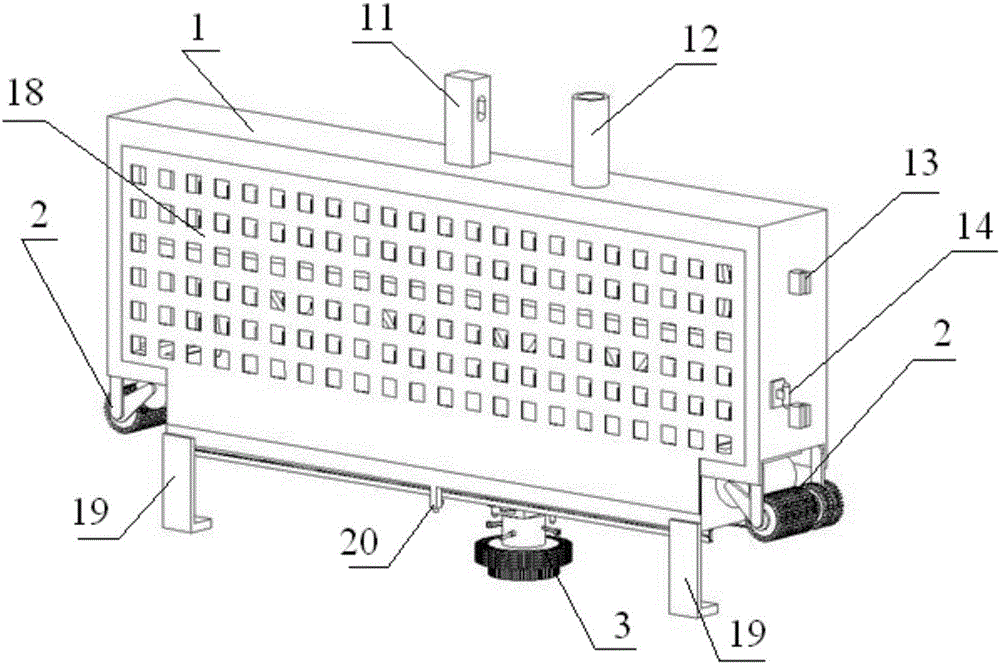

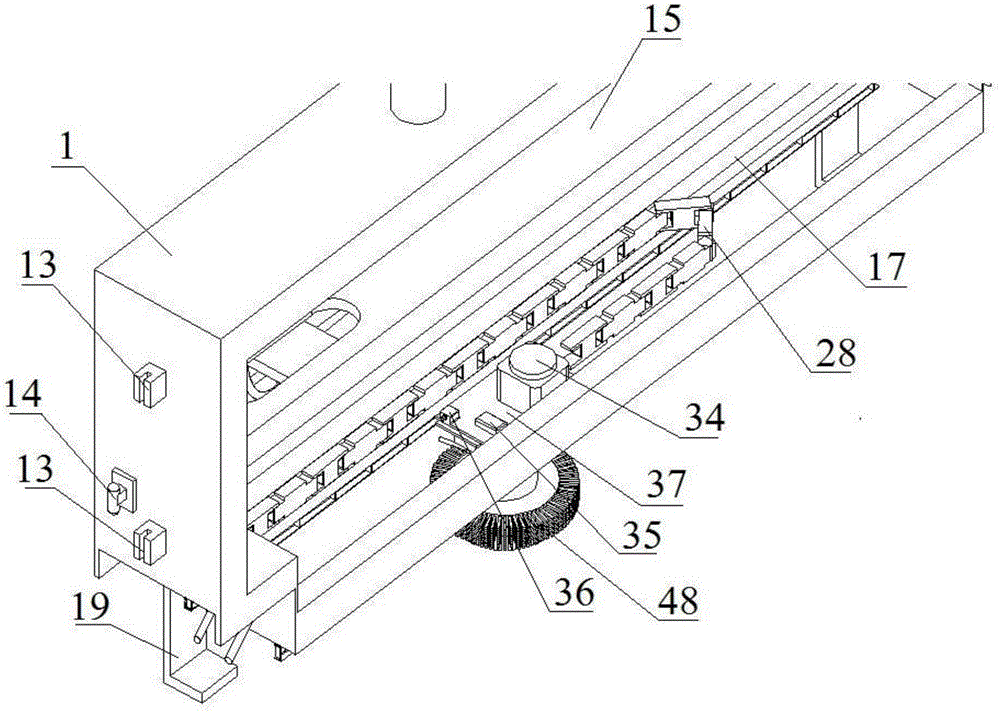

[0061] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 with Figure 9 Shown:

[0062] The frame-type PX pump station sluice gate guide rail automatic cleaning machine provided by the present invention includes a frame 1, a longitudinal cleaning system 2, a horizontal cleaning system 3 and a control system 4, wherein the frame 1 is embedded in the sluice gate guide rail 6, and the frame 1 can move along the The angle steel 10 in the guide rail 6 of the sluice gate slides up and down. The longitudinal cleaning system 2 is respectively arranged on both sides of the frame 1 for cleaning the guide rail 6 on both sides and the vertical surface 7 of the rectangular sealing frame on the wall 5. The horizontal cleaning system 3 is assembled on the The bottom of the frame 1 is used for cleaning the lintel 8 and the bottom sill 9 , and the control system 4 controls the work of the longitudinal cleaning system 2 and the horizontal cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com