Method and device for realizing flexible inner support of friction stir welding by using electromagnetic technology

A friction stir welding and friction stir technology, which is used in non-electric welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of unsuitable closed structure, complex structure, difficult to take out, etc. Volume, easily adjustable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

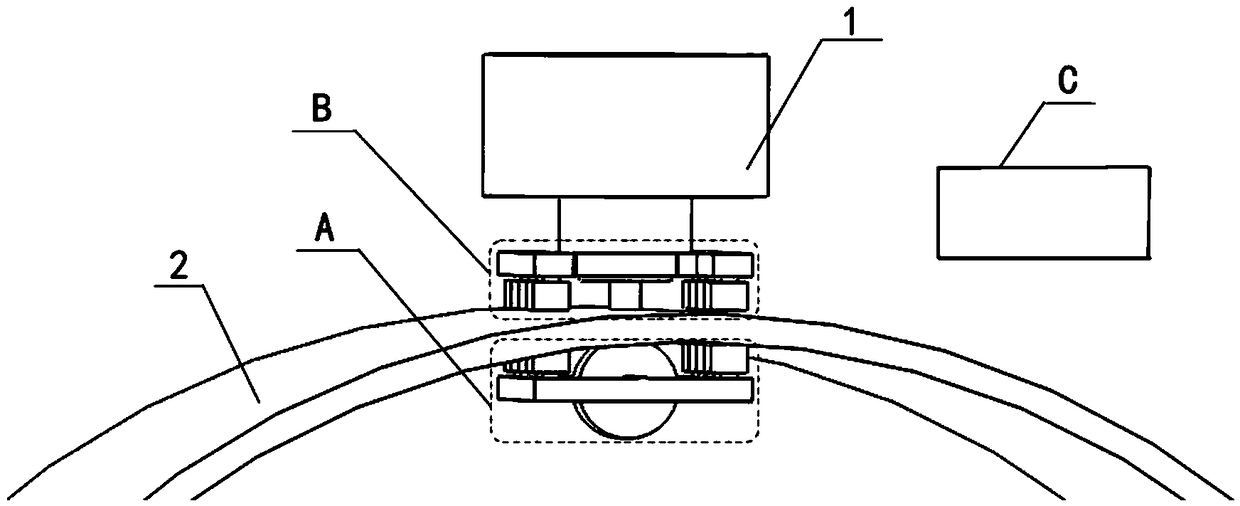

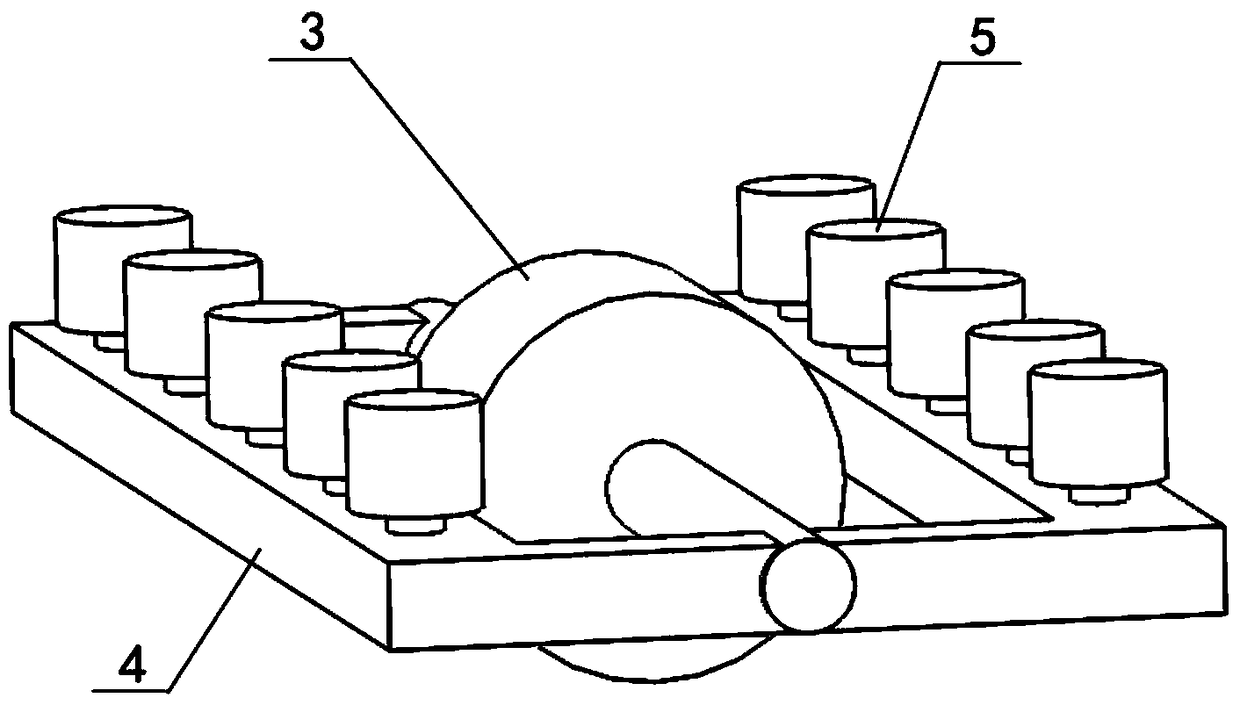

[0054] The above method and device are used to realize the internal support and welding of the friction stir welding of the annular weld seam of the aluminum alloy cylinder.

[0055] Step 1: Clamp and fix the weldment 2 of the aluminum alloy cylinder structure on a rotary positioner with rollers, and set the rotation rate of the positioner according to the welding speed requirements of friction stir welding. Use the control panel of the friction stir welding equipment to adjust the position of the head 1 to be directly above the weld to be welded, and use the fine-tuning handwheel to adjust the distance between the stirring head and the surface of the weldment 2 to make it just in contact.

[0056] Step 2, adjust the axial distance of the external electromagnet 7 on the external electromagnetic support device B and the angle of the connecting rod of the support frame, so that the distance between the end surface of the external electromagnet 7 and the surface of the weldment 2 ...

Embodiment 2

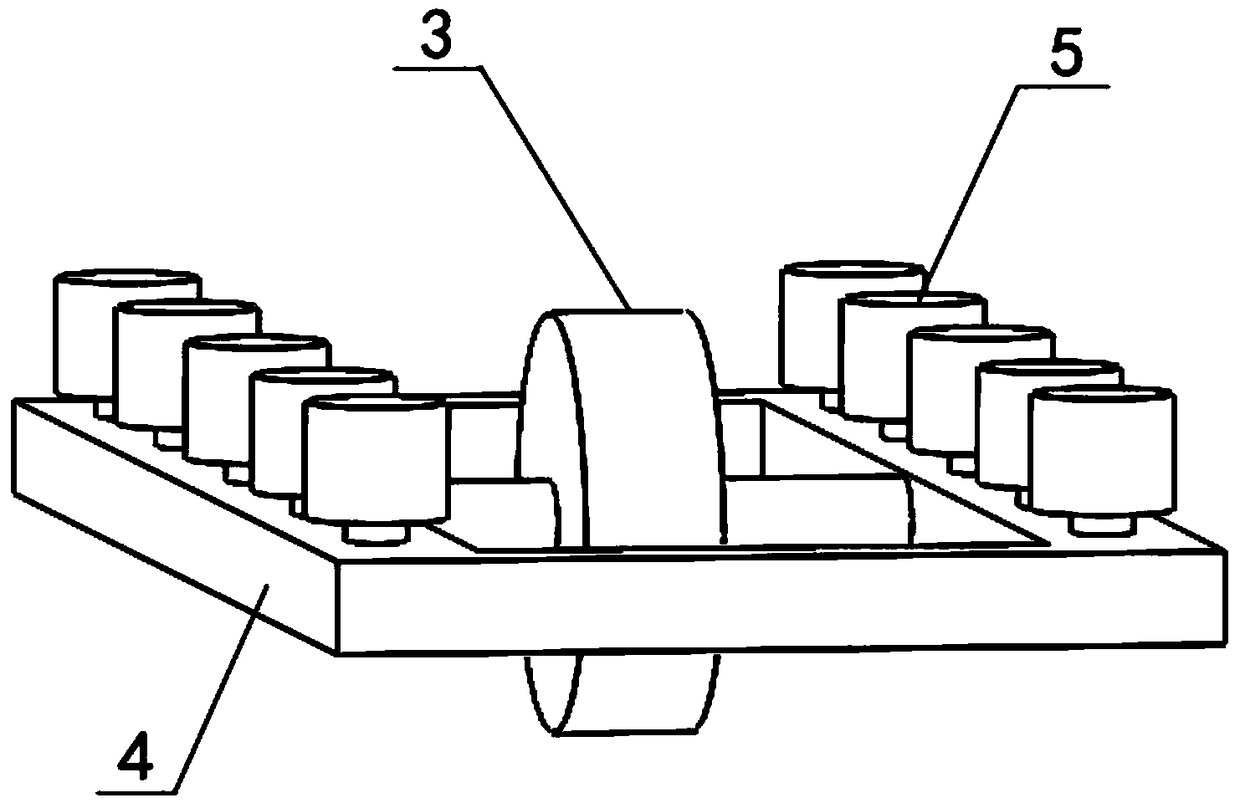

[0061] The method and the device are used to realize the internal support and welding of the friction stir welding of the longitudinal weld seam of the aluminum alloy cylinder.

[0062] Step 1: Clamp and fix the weldment 2 of the aluminum alloy cylinder structure on the workbench, adjust the position of the machine head 1 through the control panel of the friction stir welding equipment to be directly above the weld to be welded, and use the fine-tuning handwheel to adjust the stirring head and the surface of the weldment distance so that it just touches.

[0063] Step 2, adjust the axial distance of the external electromagnet 7 on the external electromagnetic support device B and the angle of the connecting rod of the support frame, so that the distance between the end surface of the external electromagnet 7 and the surface of the weldment 2 is the diameter of the stirring needle d+0.5mm, and the electrical control of the support device Turn on the power switch of the external...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com