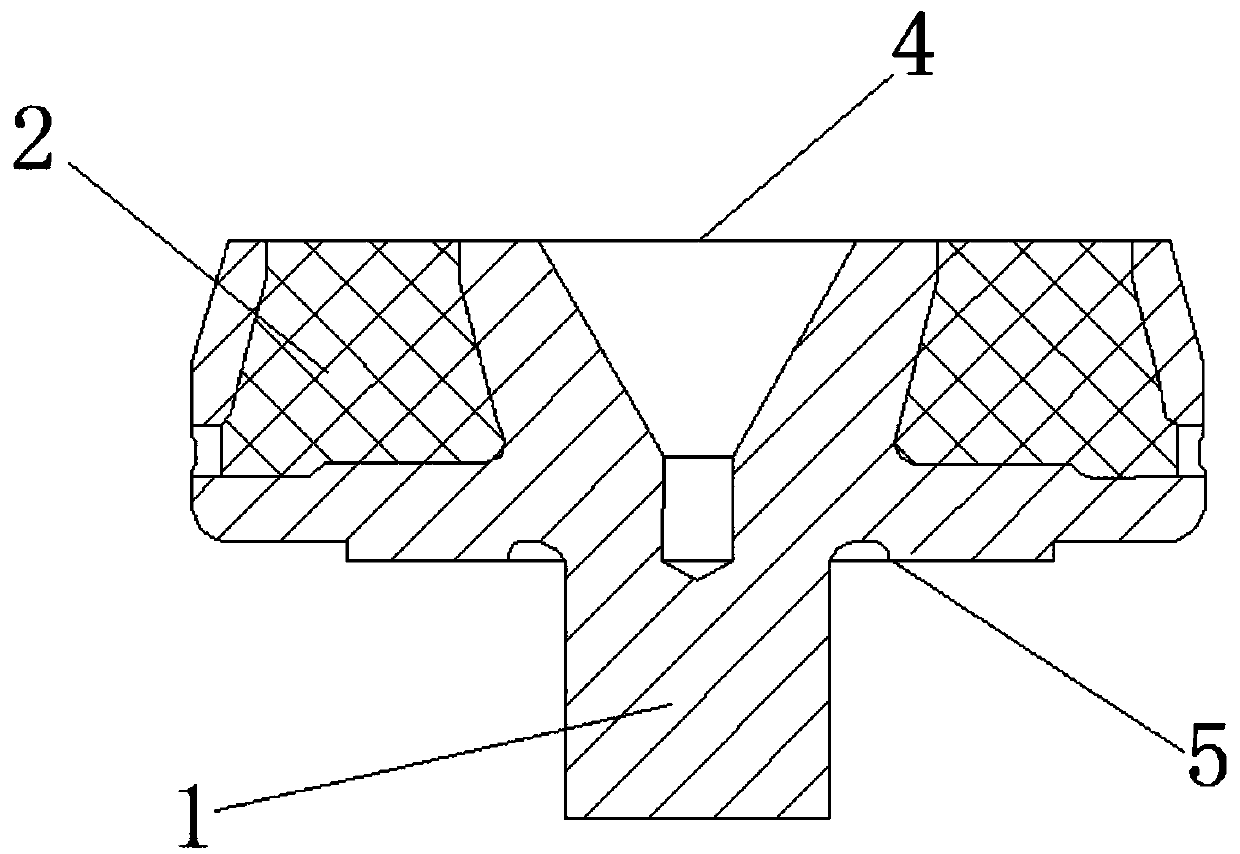

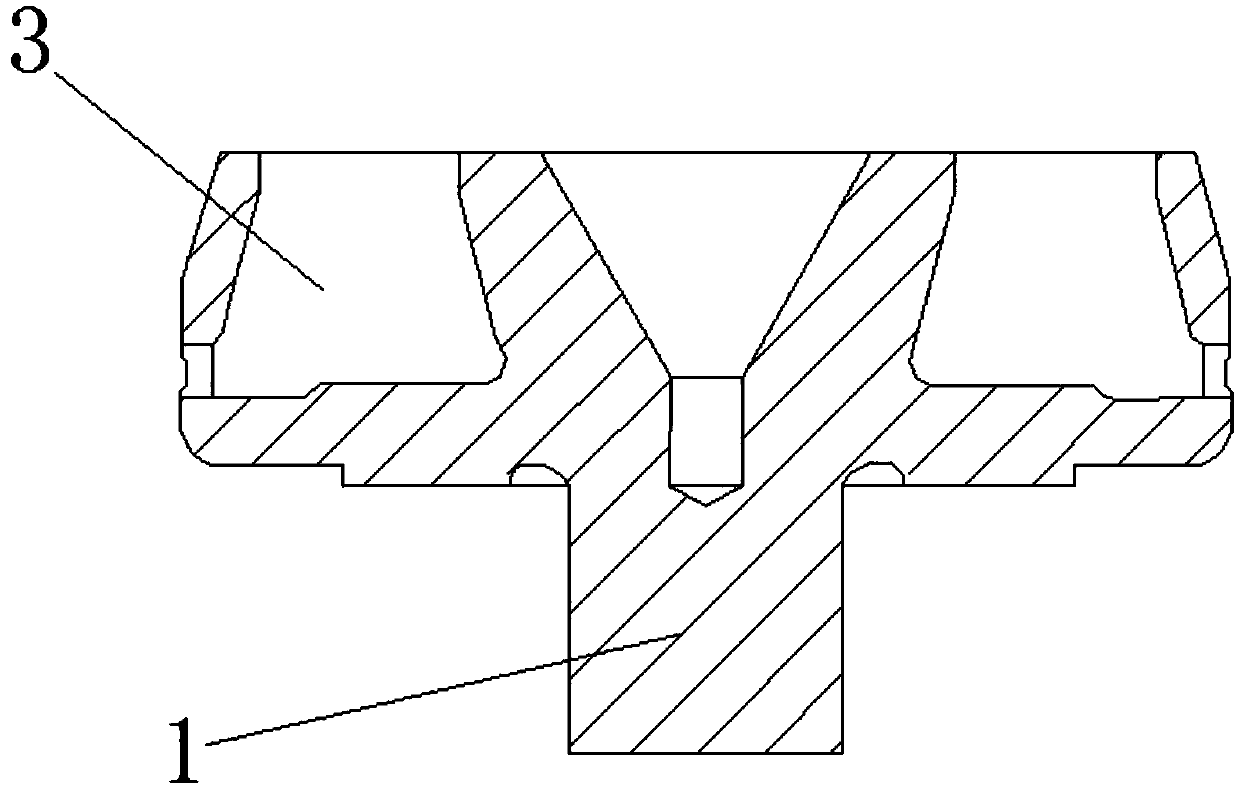

A sealing component and its processing method

A technology of sealing components and processing methods, which is applied in the direction of metal processing, metal processing equipment, manufacturing tools, etc., and can solve the problem of poor sealing of dovetail groove cavity and upward plane, incomplete filling of non-metallic materials, and out-of-tolerance bonding gap of dissimilar materials and other problems to achieve the effect of reducing cracks and falling blocks, avoiding local cracks, and improving the degree of bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Step 1, use gasoline or alcohol to clean the nest 2 made of polytetrafluoroethylene SFB-1, and remove the burrs inside the dovetail groove 3 of the component body 1 made of superalloy GH696 to obtain a clean nest 2 and component body 1.

[0037] Step 2, heating the clean nest 2 and component body 1, the heating equipment is a resistance furnace; the heating temperature is 150°C, and the heating time is 15 minutes to obtain the heated nest and component body.

[0038] Step 3, press the heated insert into the dovetail groove of the heated component body to obtain the assembled sealing component; wherein the working pressure of the press is 0.5 MPa.

[0039] Step 4: Use a CNC lathe to cut the sealing assembly. During the cutting process, the machining chips are smoothly discharged in a direction away from the processing surface; and the cutting process parameters for the cutting process are: the spindle speed is 800r / min, and the feed rate is 0.01 mm / r, the cutting depth ...

Embodiment 2

[0042] Step 1, use gasoline or alcohol to clean the nest 2 made of polytetrafluoroethylene SFB-1, and remove the burrs inside the dovetail groove 3 of the component body 1 made of superalloy GH696 to obtain a clean nest 2 and component body 1.

[0043] Step 2, heating the clean nest 2 and component body 1, the heating equipment is a resistance furnace; the heating temperature is 160°C, and the heating time is 8 minutes to obtain the heated nest and component body.

[0044] Step 3, press the heated insert into the dovetail groove of the heated component body to obtain the assembled sealing component; wherein the working pressure of the press is 0.7MPa.

[0045]Step 4: Use a CNC lathe to cut the sealing assembly. During the cutting process, the machining chips are smoothly discharged in a direction away from the processing surface; and the cutting process parameters for the cutting process are: the spindle speed is 1000r / min, and the feed rate is 0.1 mm / r, the cutting depth for...

Embodiment 3

[0048] Step 1, use gasoline or alcohol to clean the nest 2 made of polytetrafluoroethylene SFB-1, and remove the burrs inside the dovetail groove 3 of the component body 1 made of superalloy GH696 to obtain a clean nest 2 and component body 1.

[0049] Step 2, heating the clean nest 2 and component body 1, the heating equipment is a resistance furnace; the heating temperature is 155°C, and the heating time is 10 minutes to obtain the heated nest and component body.

[0050] Step 3, press the heated insert into the dovetail groove of the heated component body to obtain the assembled sealing component; wherein the working pressure of the press is 0.6 MPa.

[0051] Step 4, use a CNC lathe to cut the sealing assembly, and during the cutting process, the machining chips are smoothly discharged in a direction away from the processing surface; and the cutting process parameters of the cutting process are: the spindle speed is 900r / min, and the feed rate is 0.05 mm / r, the cutting dep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com