Processing technology and dynamic balance fixture of flywheel assembly for diesel engine

A processing technology, diesel engine technology, applied in flywheels, manufacturing tools, metal processing equipment, etc., can solve the problems of poor dynamic balance stability, low installation accuracy of flywheel assembly, etc., to increase the bonding force, improve dynamic balance detection accuracy and dynamic balance Balanced quality stability and small error in test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

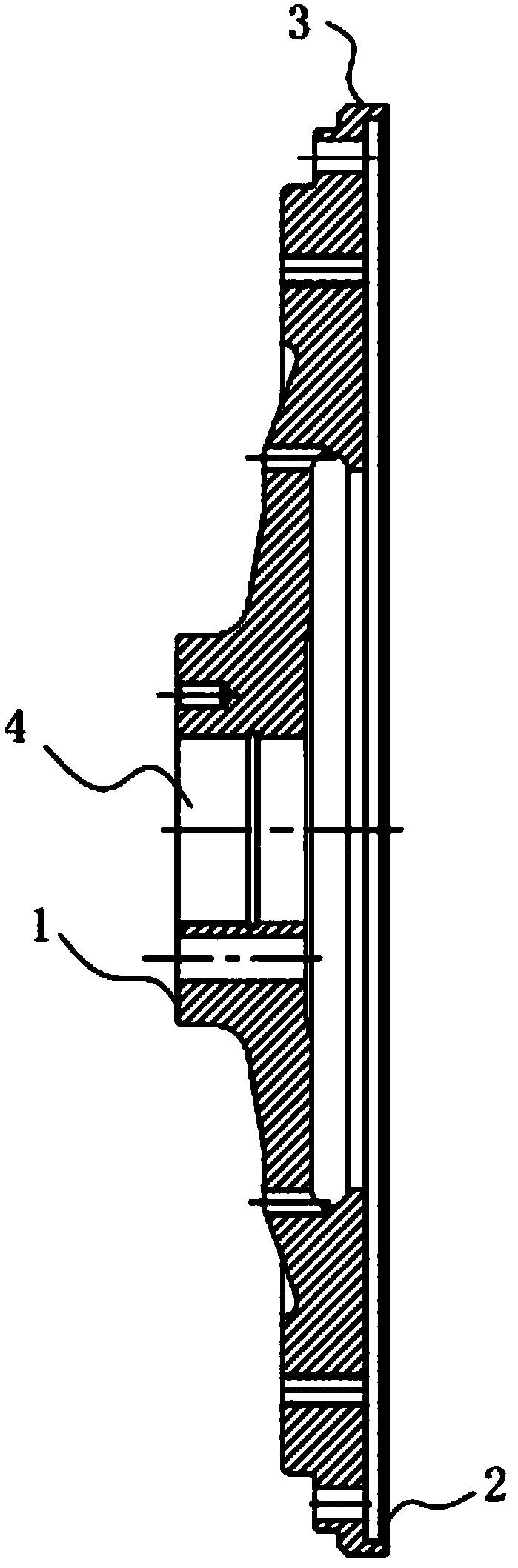

[0032] figure 1 It is a structural schematic diagram of a flywheel in an embodiment of the present invention, a diesel engine flywheel assembly process, comprising the following steps:

[0033] Step 1: Small end face 1 of the flywheel for rough turning, reserve 1.5mm-2.0mm for finishing allowance on one side; large end face 2 of flywheel for rough turning, reserve 1.5mm-2.0mm for finishing allowance on one side ;

[0034] Step 2: Use fan-shaped special fixtures to clamp on the 3rd circumference of the largest outer circle of the flywheel, and use the 3rd circumference of the largest outer circle of the flywheel, the large end face 2 of the flywheel, and the small end face 1 of the flywheel to meet the design requirements;

[0035] Step 3: Use fan-shaped special clamps to clamp the outer peripheral surface of the installation place of the flywheel ring gear on the flywheel, and use the outer peripheral surface of the ring gear installation location and the small end face 1 of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Central angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com