Apparatus and method for spectrum based monitoring of chemical mechanical polishing

A technology of spectrum and reference spectrum, which is applied in the direction of grinding devices, grinding machine tools, grinding tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

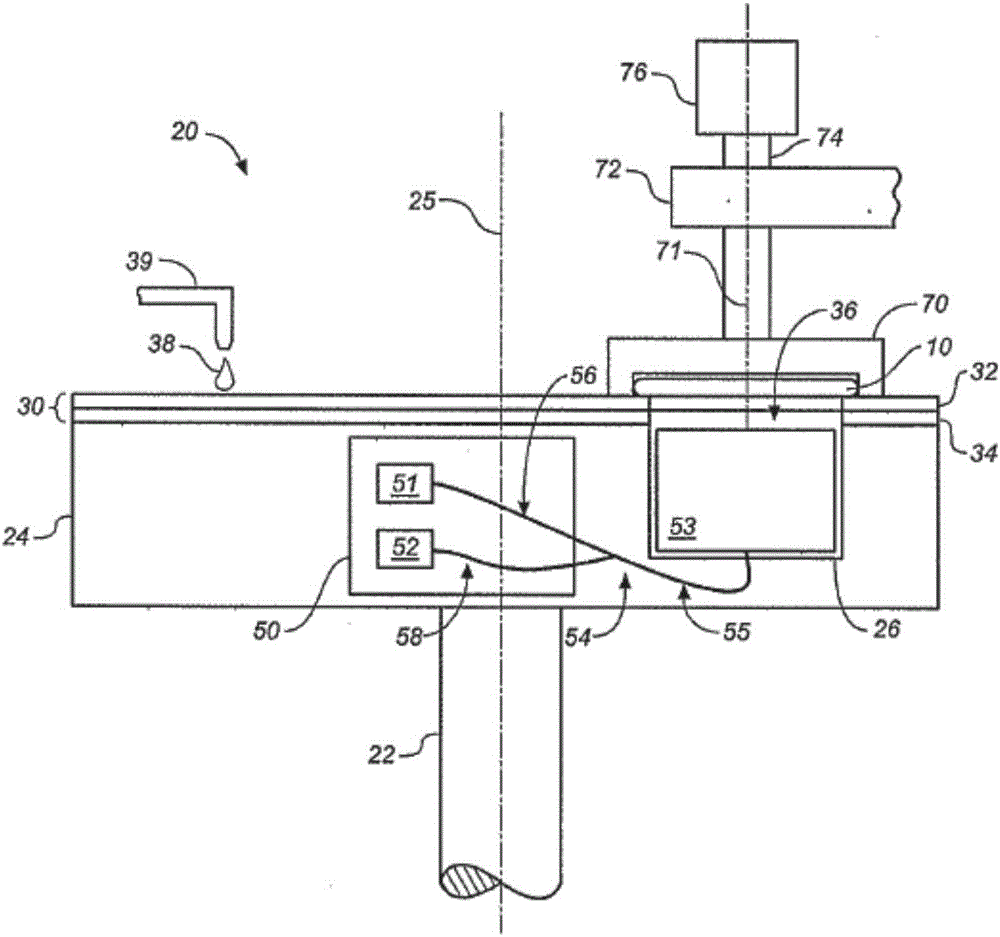

[0074] figure 1 Grinding equipment 20 that can be used to grind a substrate 10 is identified. The grinding device 20 includes a rotatable disc platform 24 on which a grinding pad 30 is disposed. The platform is rotatable about axis 25 . For example, a motor can turn a drive rod 22 to rotate the platform 24 . The polishing pad 30 can be removably secured to the platform 24, for example, with a layer of adhesive. When exhausted, the abrasive pad 30 can be removed and replaced. The polishing pad 30 may be a two-layer polishing pad having an outer abrasive layer 32 and a softer back abrasive layer 34 .

[0075] Optical access 36 through the polishing pad is provided by including a hole (ie, a hole through the polishing pad) or a solid window. The rigid window can be affixed to the polishing pad, although in some implementations the rigid window can be supported on the platform 24 and protrude into holes in the polishing pad. The polishing pad 30 is generally placed on the pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com