Turnout rotary charge-control electric cabinet for mine

A technology of electric control box and turnout, which is applied to remote control signals, railway car body parts, railway signals and safety, etc., can solve the problems of simple and crude hydraulic control system, waste of roadway transportation time, and reduced mine transportation capacity, etc. Easy process control, compact structure and small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

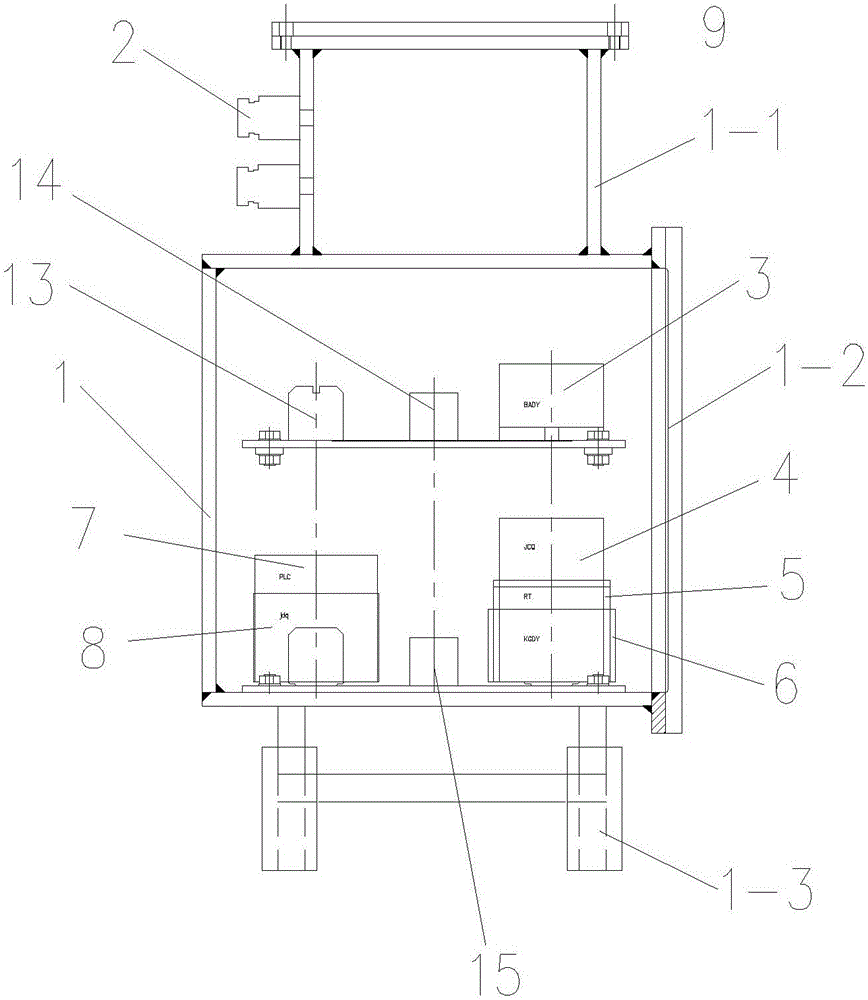

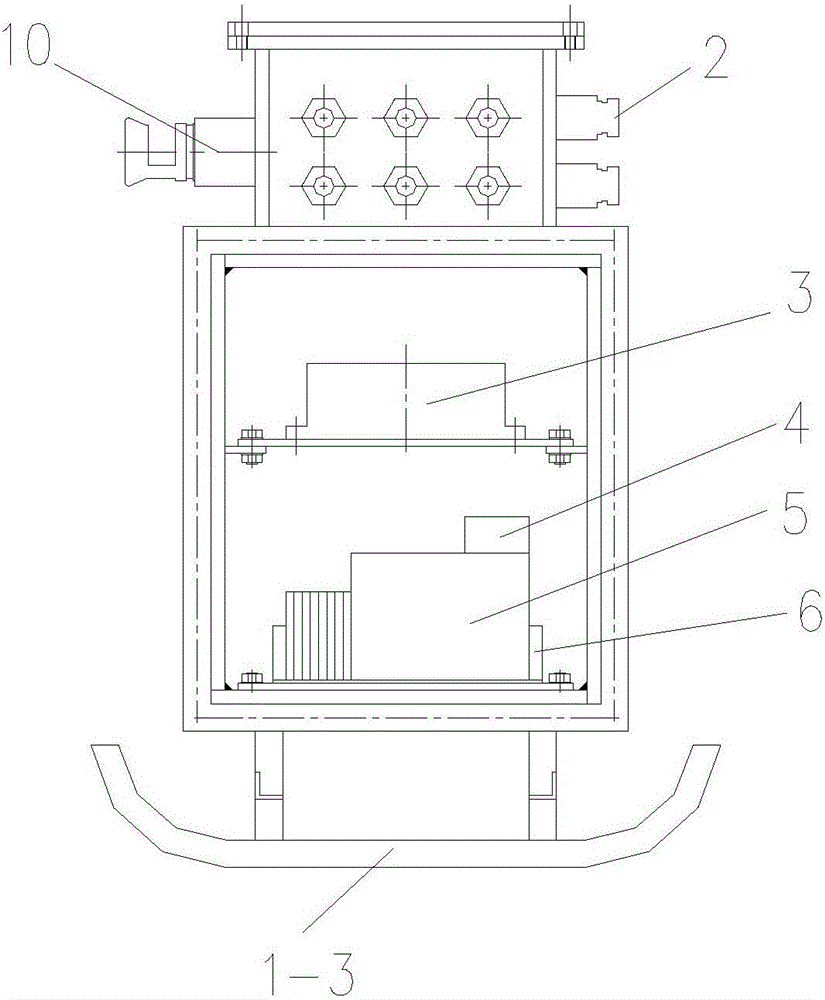

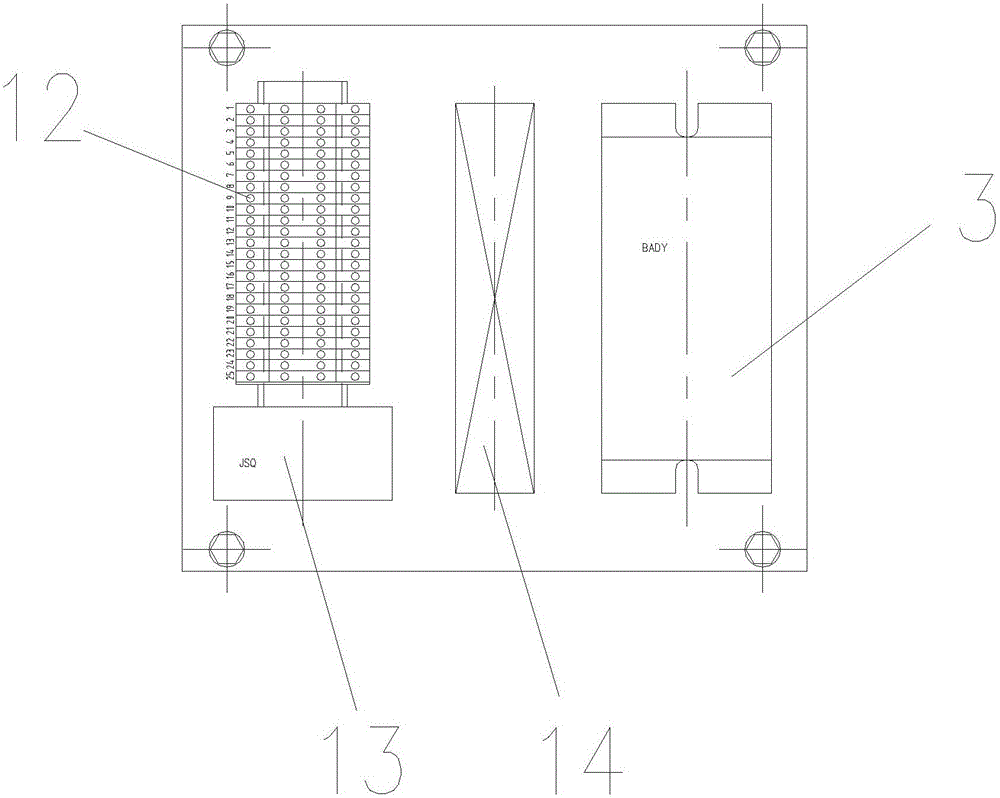

[0057] Such as Figure 1 to Figure 7 The electric control box for mine turnout rotary control shown includes a box body 1 and a circuit control module for controlling the rotation and reversing of the turnout 21, and the circuit control module includes:

[0058] The data processing module is used for wirelessly receiving the control command sent by the transmitter 22, and sending the driving command according to the control command;

[0059] The data collection module is used to collect the working state of the turnout 21, and send the collected working state to the data processing module;

[0060] The hydraulic drive module is used to receive the drive command sent by the data processing module, and complete the corresponding action of turning and reversing the switch 21 according to the drive command;

[0061] The data acquisition module includes a pressure detection unit 7-3 arranged on the switch 21, a first position detection unit 7-1 arranged on the first branch and a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com