Convenient-to-move bracket for steel pipe processing

A technology of brackets and steel pipes, which is applied in the direction of external frames, manual conveying devices, packaging, etc., can solve the problems of not having center height adjustment, affecting the processing progress of steel pipes, and affecting the processing accuracy of steel pipes, so as to achieve convenient alignment, simple structure, The effect of reducing the coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing:

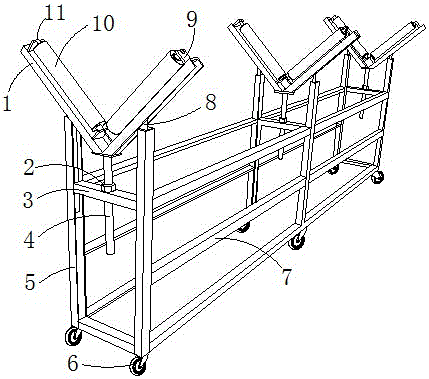

[0016] like figure 1 As shown, the bracket for steel pipe processing that is easy to move includes a base and supporting rollers 10, and the base is formed by welding a cross bar 7, a vertical bar 5, and an adjustment bottom bar 3, and a universal wheel 6 is provided under the base. The roller seat 1 and the screw 4 are welded to form a Y-shaped structure. There is a through hole in the middle of the adjustment bottom rod 3, and the screw 4 is movably connected in the through hole. An adjustment device 2 is also provided on the screw 4. There are two idler end seats 9 welded on the top of the idler seat 9, and an idler shaft 11 is arranged between the idler end seats 9, and the idler 10 is emptied on the idler shaft 11, and the bottom of each idler seat 1 is welded with a lift Rod 8, elevating rod 8 activities act in the vertical rod 5.

[0017] like figure 1 As shown, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com