Elevator driving control and energy saving integrated system and method

A drive control and drive system technology, applied in the field of elevator drive control and energy-saving integrated systems, can solve the problems of low energy utilization rate, disadvantageous elevator drive system's own resources, and imperfect system integration, so as to achieve charge and discharge management. Accurate and efficient, fast fault signal processing, obvious effect of energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

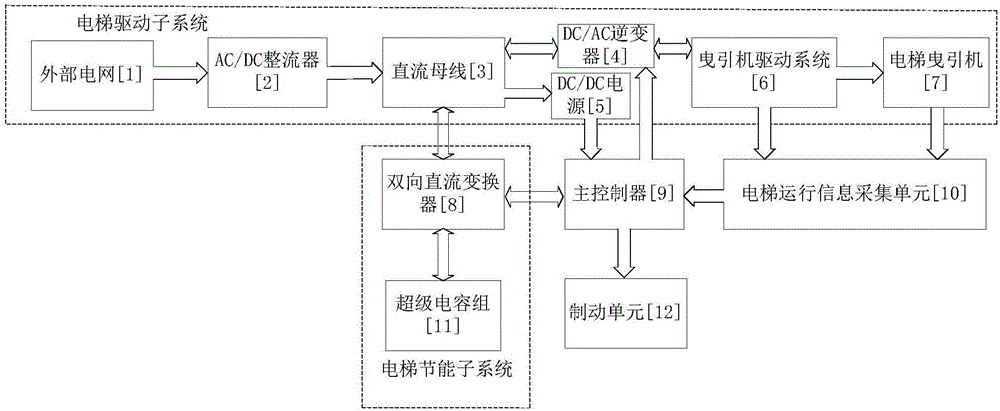

[0017] combine figure 1 , an elevator drive control and energy-saving integrated system of the present invention, comprising an AC / DC rectifier 2, a DC bus 3, a DC / AC inverter 4, a traction machine drive system 6, an elevator traction machine 7, and a supercapacitor bank 11. Bidirectional current converter 8, DC / DC power supply module 5, main control unit 9, elevator operation information collection unit 10, braking unit 12;

[0018] The external AC grid 1 is connected to the DC bus 3 through the AC / DC rectifier 2, the DC bus 3 is connected to the motor drive control subsystem 6 through the DC / AC inverter 4, and the motor drive control subsystem 6 is connected to the elevator traction machine 7, The AC / DC converter 2 is connected to the external AC grid 1, and the DC bus is connected to the AC / DC converter 2 and the DC / AC inverter 4. When the elevator traction machine 7 is running, the external AC grid 1 passes through the AC / DC converter 2. The DC / AC converter 4 provides ene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com