A kind of hexagonal flaky cobalt trioxide nanometer material and preparation method thereof

A technology of tricobalt tetroxide and hexagonal flakes, which is applied in the field of nanomaterials, can solve problems such as insufficient preparation conditions, achieve narrow particle size distribution, high yield, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

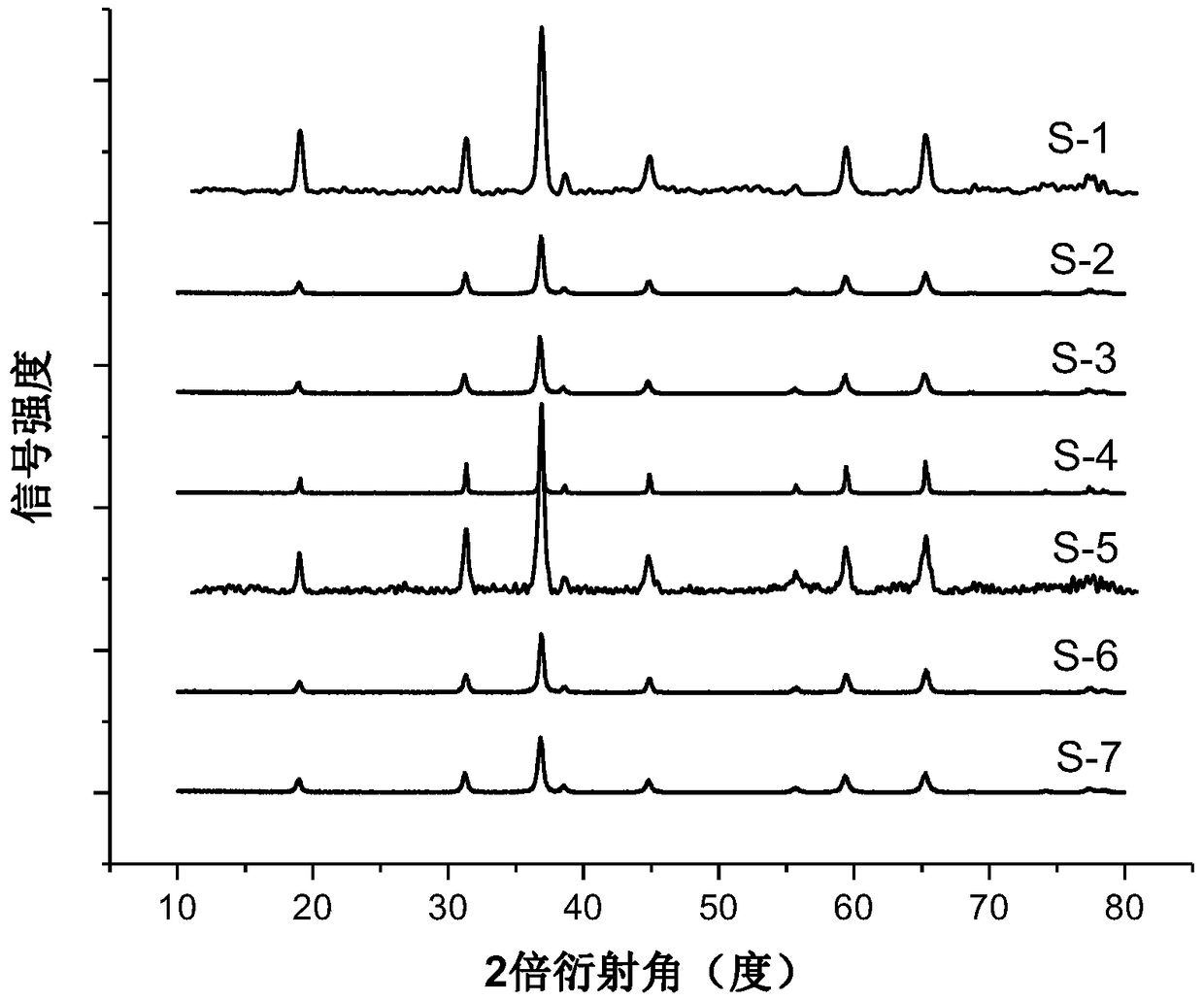

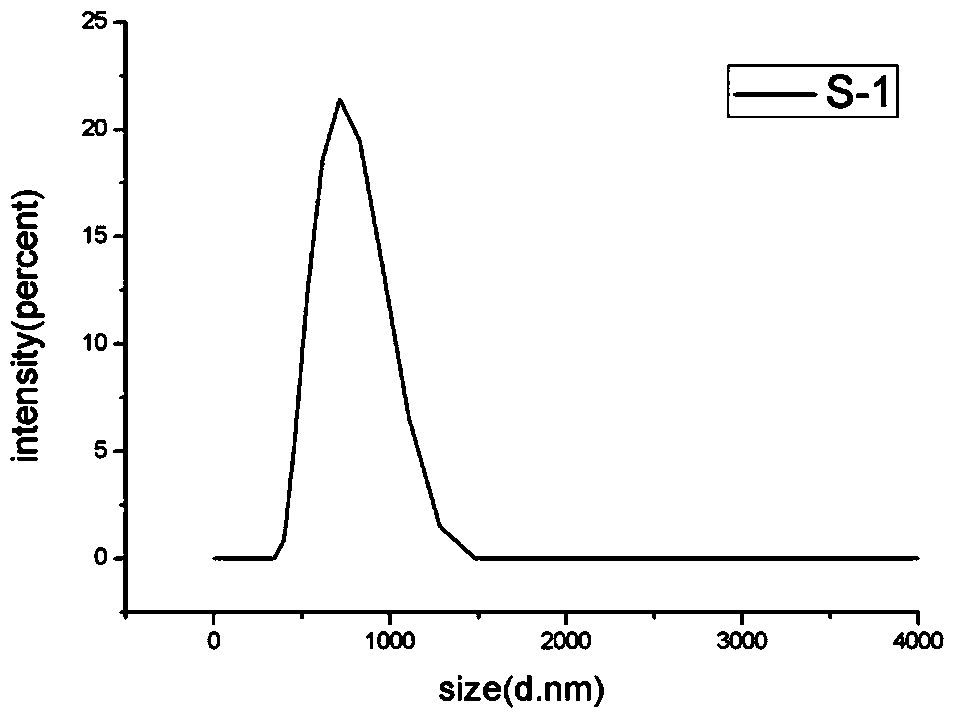

[0037] Dissolve 2.5 mmol of cobalt sulfate heptahydrate in 100 ml of deionized water to form solution A; dissolve 1.2 g of DTC in 50 ml of deionized water, add 2.5 g of hexylamine, and stir for 10 min to form solution B. Under vigorous stirring, slowly add solution B to solution A to form mixture C. After stirring for 30 minutes, pour mixture C into a 100ml reactor lined with polytetrafluoroethylene with a filling degree of 70% and place it at 80°C React in an oven for 48 hours. After the reaction, the resulting product is washed, filtered, dried overnight in a vacuum at 70°C, and then calcined at 500°C for 2 hours to obtain hexagonal flake cobalt tetroxide, which is referred to as S-1.

Embodiment 2

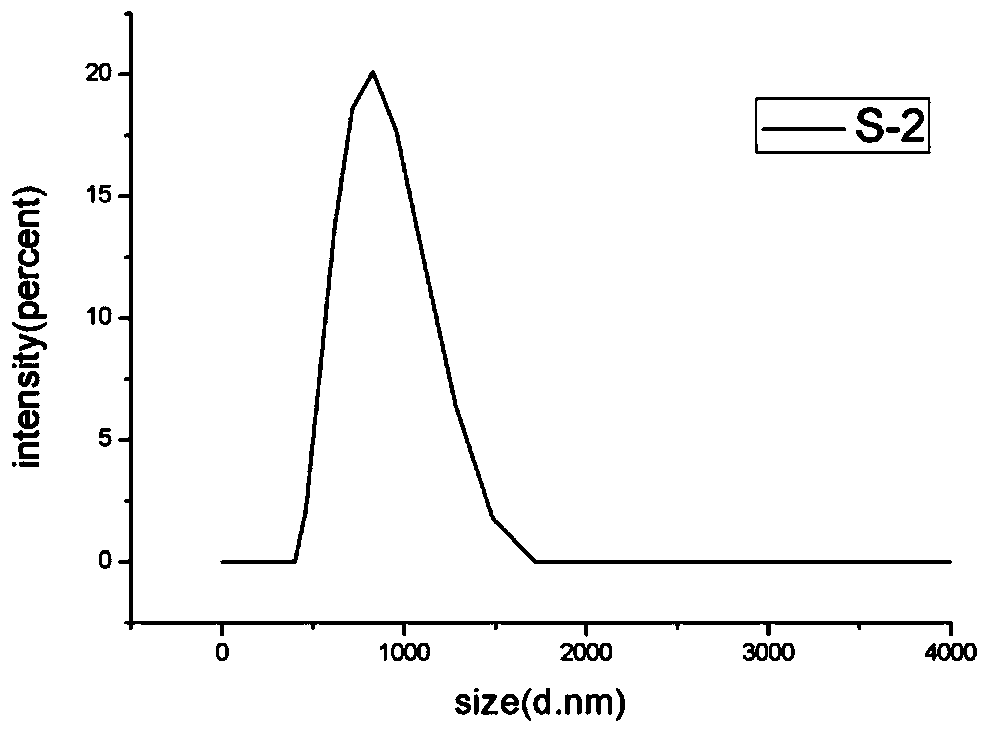

[0039] Dissolve 250mmol of cobalt nitrate hexahydrate in 100ml of deionized water to form solution A; dissolve 7.5g of SE 30 in 50ml of deionized water, add 25g of dipropylamine and stir for 10min to form solution B. Under vigorous stirring, slowly add solution B to solution A to form mixture C. After stirring for 40 minutes, pour mixture C into a 100ml reactor lined with polytetrafluoroethylene with a filling degree of 70% and place it at 220°C After reacting in an oven for 10 hours, the product obtained after the reaction was washed, filtered, dried overnight in a vacuum at 50°C, and then calcined at 400°C for 3 hours to obtain hexagonal flake cobalt tetroxide, denoted as S-2.

Embodiment 3

[0041] Dissolve 100mmol of cobalt acetate tetrahydrate in 100ml of deionized water to form solution A; dissolve 5g of Tween80 in 50ml of deionized water, add 20g of tripropylamine, and stir for 10min to form solution B. Under vigorous stirring, slowly add solution B to solution A to form mixture C. After stirring for 30 minutes, pour mixture C into a 100ml reactor lined with polytetrafluoroethylene with a filling degree of 70% and place it at 150℃ After reacting in an oven for 20 hours, the product obtained after the reaction was washed, filtered, dried overnight in a vacuum at 90°C, and then calcined at 300°C for 5 hours to obtain hexagonal flake cobalt tetroxide, denoted as S-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com