Method for preparing baking-free brick by utilizing sludge

A technology of unburned bricks and sludge, which is applied in the field of preparing unburned bricks from sludge, which can solve the problems of poor water absorption, durability, corrosion resistance, shale, large amount of sludge added, sludge stability and misalignment, etc. Achieve the effects of reducing water absorption, improving sludge performance, and inhibiting the generation of odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

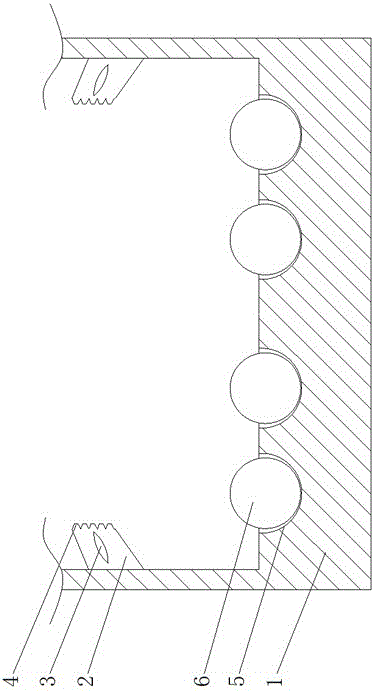

Image

Examples

Embodiment

[0026] Embodiment: A kind of method of utilizing sludge to prepare burn-free bricks of this example, its steps are:

[0027] a. Use sludge from rivers and printing and dyeing plants, use mud-water separation equipment to reduce the moisture content of the sludge to 20%-30%, and obtain 2000G of river sludge and 1000G of sludge from printing and dyeing plants;

[0028] b. Then put the sludge into the sludge reaction tank for fermentation and drying, then pulverize the sludge, screen out the coarse particles above 10mm and stir and mature;

[0029] c. Add 750G of soil curing agent to the dehydrated sludge. The soil curing agent includes 75G of cement, 150G of fly ash, 75G of activator, 75G of oxidant, 225G of cementitious material, and 150G of volcanic ash. Put it into the mixing tank 1 for stirring Mix evenly until the sludge reaches normal temperature, then add 2250G of construction waste, 750G of power plant fly ash, 750G of cement and sufficient water, then age the mixture...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com