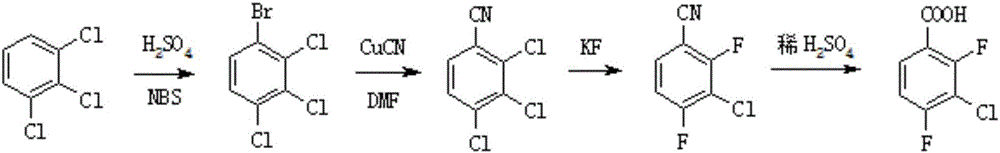

Synthesis method of 3-chloro-2,4-difluorobenzoic acid

A technology of difluorobenzoic acid and a synthesis method, which is applied in the field of synthesis of 3-chloro-2,4-difluorobenzoic acid, can solve the problems of unfavorable industrial production, harsh reaction conditions, large pollution in the reaction process, etc. The effect of industrialized production, mild reaction conditions and low pressure of the three wastes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A kind of synthetic method of 3-chloro-2,4-difluorobenzoic acid, the method comprises the steps:

[0025] (1) Pour 300mL of sulfuric acid into a dry 500mL four-necked bottle, add 54.5g of 1,2,3-trichlorobenzene in batches under stirring, cool down to 0-10°C after it is completely dissolved, and then add in batches 55.0gNBS, keep at this temperature for 0.5h after adding. GC tracking detection, when the content of 1,2,3-trichlorobenzene is less than or equal to 2%, the bromination reaction is ended;

[0026] (2) Pour the mixture prepared in step (1) into 1000mL of ice-water mixture, separate the oil layer, wash the oil layer twice with 200mL of cold water respectively, separate out a light yellow granular solid, filter it with suction, and weigh it after drying. Quantity, get 70.7g of 1-bromo-2,3,4-trichlorobenzene, the content is 98.021% (GC), the molar yield is 90.5% (based on 1,2,3-trichlorobenzene), melting range 58.2~60.7℃;

[0027] (3) Pour 300mL of DMF into a d...

Embodiment 2

[0034] A kind of synthetic method of 3-chloro-2,4-difluorobenzoic acid, the method comprises the steps:

[0035] (1) Pour 220mL of sulfuric acid into a dry 500mL four-neck bottle, add 54.5g of 1,2,3-trichlorobenzene in batches under stirring, cool down to 0-20°C and add in batches after it is completely dissolved 58.0g NBS, keep at this temperature for 0.5 hours after adding. GC tracking detection, when the content of 1,2,3-trichlorobenzene is less than or equal to 2%, the bromination reaction is ended;

[0036] (2) Pour the mixture prepared in step (1) into 1000mL ice-water mixture, separate the oil layer, wash the oil layer twice with 300mL cold water respectively, separate out light yellow granular solid, suction filter, dry and weigh Quantity, get 72.5g of 1-bromo-2,3,4-trichlorobenzene, the content is 95.893% (GC), the molar yield is 92.8% (based on 1,2,3-trichlorobenzene), melting range 53.8~68.3℃;

[0037] (3) Pour 400mL of DMF into a dry 500mL four-neck bottle, drop...

Embodiment 3

[0044] (1) Pour 300mL of sulfuric acid into a dry 500mL four-neck bottle, add 54.5g of 1,2,3-trichlorobenzene in batches under stirring, and add 60.0 g of After adding gNBS, keep it warm at this temperature and track and detect it by GC. When the content of 1,2,3-trichlorobenzene is ≤2%, the bromination reaction is ended;

[0045] (2) Pour the mixture prepared in step (1) into 1500mL ice-water mixture, separate the oil layer, wash the oil layer 3 times with 300mL cold water respectively, separate out light yellow granular solid, suction filter, dry and weigh Quantity, get 73.1g of 1-bromo-2,3,4-trichlorobenzene, the content is 95.739% (GC), the molar yield is 93.5% (based on 1,2,3-trichlorobenzene), melting range 56.8~59.6℃;

[0046] (3) Pour 320mL of DMF into a dry 500mL four-neck bottle, drop 30.0g of cuprous cyanide under stirring, and then add the 1-bromo-2,3,4- Trichlorobenzene, heat preservation reaction at 100-170 ° C and GC detection, when the content of 1-bromo-2,3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com