Method for preparing trialkylsilanol

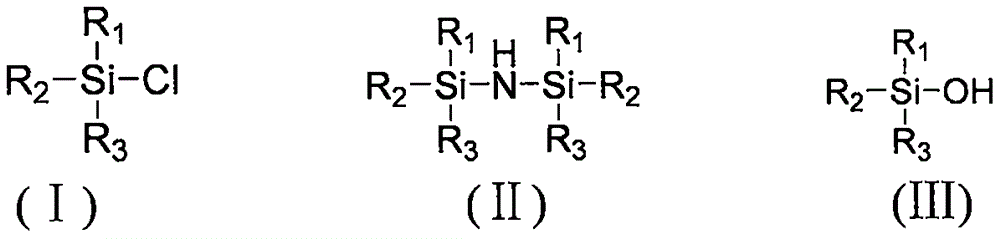

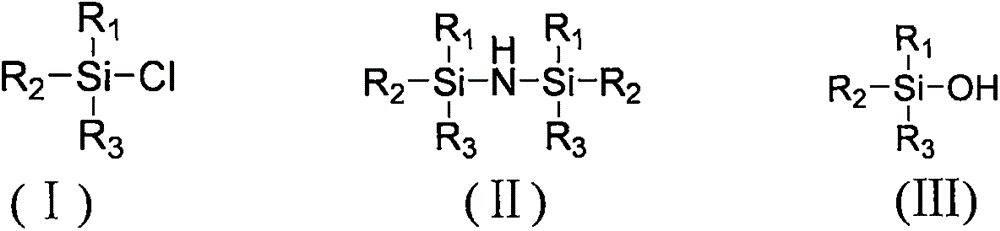

A technology of trihydrocarbyl silanol and hydrocarbyl chlorosilane, which is applied in the field of preparation of trihydrocarbyl silanol, can solve the problems of low reactivity, achieve the effects of improving yield and purity, avoiding condensation reaction, and being easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Add 109 g of trimethylchlorosilane and 80 g of ammonium acetate into a 1000 mL four-neck flask, heat up to 130° C. under stirring, and react for 2 hours to obtain a solid-liquid mixture. At 30° C., 194 g of hexamethyldisilazane and 90 g of deionized water were added dropwise to the mixture at the same time, and the drop was completed in about half an hour. The obtained emulsion continued to stir and react for 3 hours to complete the hydrolysis reaction. Separate the upper liquid and dry it overnight in anhydrous sodium sulfate. After filtering, 291g of colorless and transparent liquid, i.e. trimethylsilanol, was obtained, with a yield of 95% and a purity of 98%. (GC).

Embodiment 2

[0018] Add 54 g of trimethylchlorosilane and 50 g of sodium acetate into a 500 mL four-necked flask, heat up to 80° C. under stirring, and react for 3 hours to obtain a solid-liquid mixture. At 25° C., 81 g of hexamethyldisilazane and 300 g of deionized water were added dropwise to the mixture at the same time, and the drop was completed in about half an hour. The obtained emulsion was stirred and reacted for 3 hours to complete the hydrolysis reaction, the upper liquid was separated and dried overnight in anhydrous sodium sulfate, and 125 g of colorless transparent liquid, i.e. trimethylsilanol, was obtained after filtration, with a yield of 92% and a purity of 97%. (GC).

Embodiment 3

[0020] Add 54 g of trimethylchlorosilane and 49 g of potassium acetate into a 500 mL four-neck flask, heat up to 100° C. under stirring, and react for 2.5 hours to obtain a solid-liquid mixture. At 25°C, 81 g of hexamethyldisilazane and 20 g of deionized water were simultaneously added dropwise to the mixture, and the drop was completed in about half an hour. The obtained emulsion was stirred and reacted for 1 hour to complete the hydrolysis reaction, filtered, and the upper layer liquid was separated and dried in anhydrous magnesium sulfate for 2 hours. After filtering, 122 g of a colorless transparent liquid, i.e., trimethylsilanol, was obtained, with a yield of 90%. Purity 96% (GC).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com