Combined desalting and anti-corrosion method of catalytic reforming device

A catalytic reforming and desalination technology, applied in the direction of catalytic reforming of naphtha, chemical instruments and methods, separation methods, etc., can solve problems such as difficult water treatment, waste of hydrocarbons, and not a very perfect treatment method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

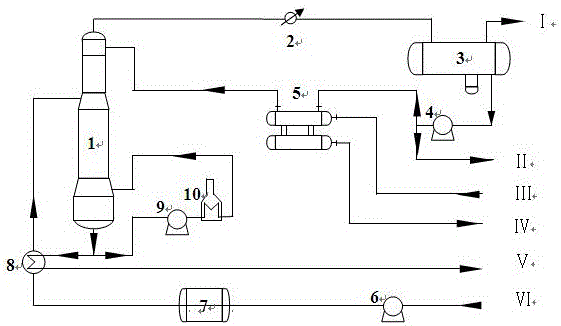

Image

Examples

Embodiment

[0053] In a 1.2 million tons / year continuous reforming unit in China, the reforming and depentane operation is extremely unstable, the pressure at the top of the tower fluctuates intermittently, and the temperature operation is not flexible. 160°C, the temperature at the bottom of the tower dropped from the normal 212±2°C to 205-208°C, and the content of C4 and C5 in the reformed oil at the bottom of the tower continued to exceed the standard. According to the method of the present invention, a dehydration and dechlorination tank is added after the feed booster pump of the depentanizer, and a high-efficiency water washing and desalination device is added on the reflux process of the liquefied gas at the top of the tower.

[0054] (1) The feed flow rate of the depentanizer tower is 110t / h, the temperature entering the tower is 147°C, the pressure at the top of the tower is 0.85MPa, and the oil flow rate at the top of the tower is 25t / h.

[0055] (2) The dehydration and dechlori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com