Anti-hard-water fabric detergent and preparation method thereof

A detergent and anti-hard water technology, applied in the direction of detergent composition, surface active detergent composition, chemical instruments and methods, etc., can solve the problems of poor washing effect, achieve good detergency, excellent washing effect, anti-corrosion Strong hard water ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

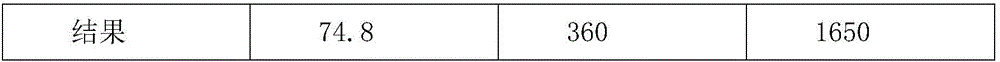

Examples

Embodiment

[0013] A hard water resistant fabric detergent, consisting of the following raw materials by weight (kg): disodium cocoamphodiacetate 12, sodium N-oleoyl-N-methyl taurate 10, lauryl monoethanolamine 9 , Cocoyl Glucoside 7, Sodium Fatty Alcohol Polyoxyethylene Ether Carboxylate 11, Isomerized Tridecyl Polyoxyethylene Ether Phosphate 8, Lauramide Propyl Hydroxysultaine 11, Sodium Fatty Acid Methyl Sulfonate 8 , sodium dodecyl diphenyl ether disulfonate 6, water 90.

[0014] A preparation method of anti-hard water fabric detergent, comprising the following steps:

[0015] (1) Take 1 / 3 of the water bath and heat it to 40°C, add N-oleoyl-N-methyl taurate sodium, isotridecyl polyoxyethylene ether phosphate, coconut oil in sequence under mechanical stirring glucoside and fatty acid sodium methyl ester sulfonate, then magnetically stirred for 7min under the condition of heating power of 250W and rotating speed of 250r / min to obtain mixture A;

[0016] (2) Take the remaining water an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com