Shape memory alloy flame-retardant fabric

A memory alloy, flame retardant fabric technology, used in fabrics, textiles, textiles and papermaking, etc., can solve the problem of high temperature resistant fabrics without dynamic thermal insulation properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

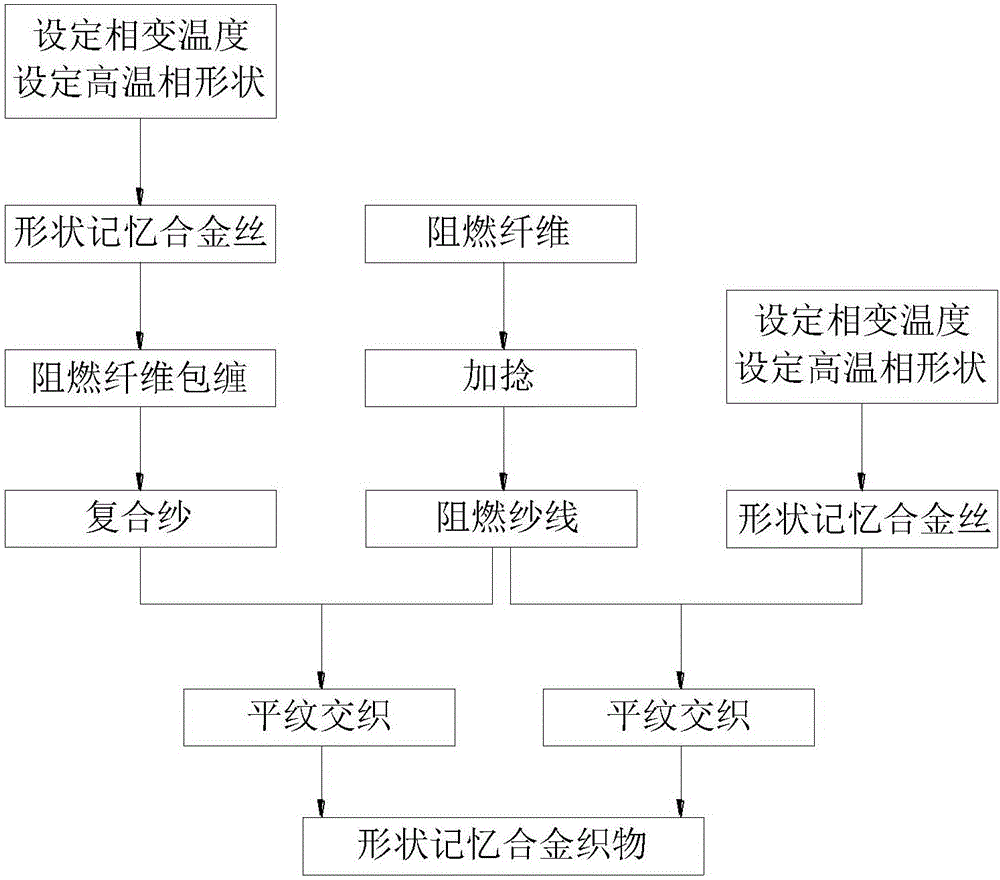

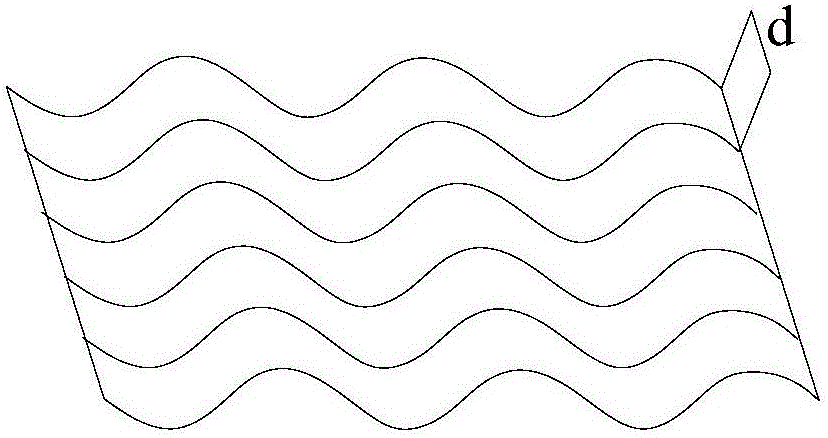

[0021] see Figures 1 to 3 , a shape memory alloy flame retardant fabric described in a preferred embodiment of the present invention, including flame retardant yarn and shape memory yarn, shape memory yarn can be shape memory alloy wire as a single yarn, can also be in the shape Memory alloy wire is a composite yarn made of core yarn wrapped with flame-retardant fibers. The composite yarn can make the fabric more comfortable. The shape memory yarn and flame retardant yarn are interwoven in plain weave, and the shape memory yarn is woven in weft yarn.

[0022] The phase transition temperature of the shape memory alloy wire is 45°C to 90°C, and the phase transition temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com