Mountainous area wind-cable-free double-rib hoisting large-span steel pipe arch section construction method

A technology that spans steel pipes and arch segments, which is applied in the construction method of double-rib hoisting large-span steel pipe arch segments without wind cables in mountainous areas. The effect of stability and high control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

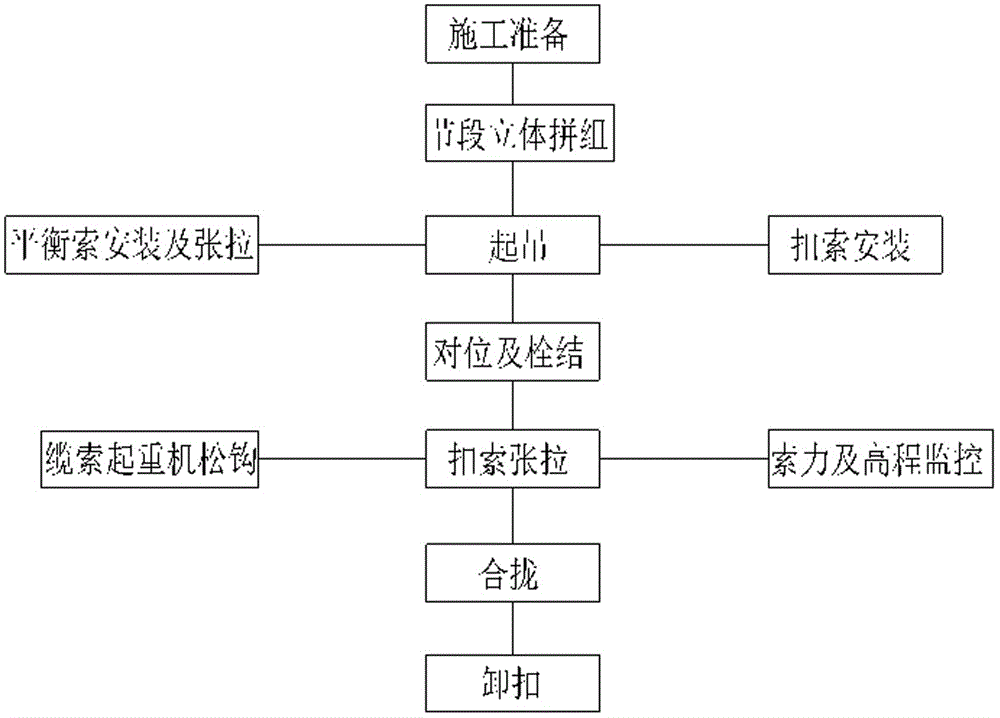

[0026] Such as figure 1 As shown, the construction method for hoisting the large-span steel pipe arch section of the double-rib hoisting of the windless cable in the mountainous area of the present invention comprises the following steps:

[0027] a. Construction preparation, complete the installation of hoisting system and preparation of construction materials;

[0028] b. Segmental three-dimensional assembly, through the use of the hoisting system, the steel pipe arch ribs are three-dimensionally assembled in four segments;

[0029] c. After the 4-segment three-dimensional assembly of steel pipe arch ribs is completed, fine lifting, alignment and bolting are carried out;

[0030] d. Tension and fixation of the bolted steel pipe arch rib 4-section buckle cable through the cable-stayed buckle-hanging system;

[0031] e. Repeat steps b to d to complete the assembly of all 4 segments of steel pipe arch ribs;

[0032] f. Closing and shackle. When all 4 sections of the steel ...

Embodiment 2

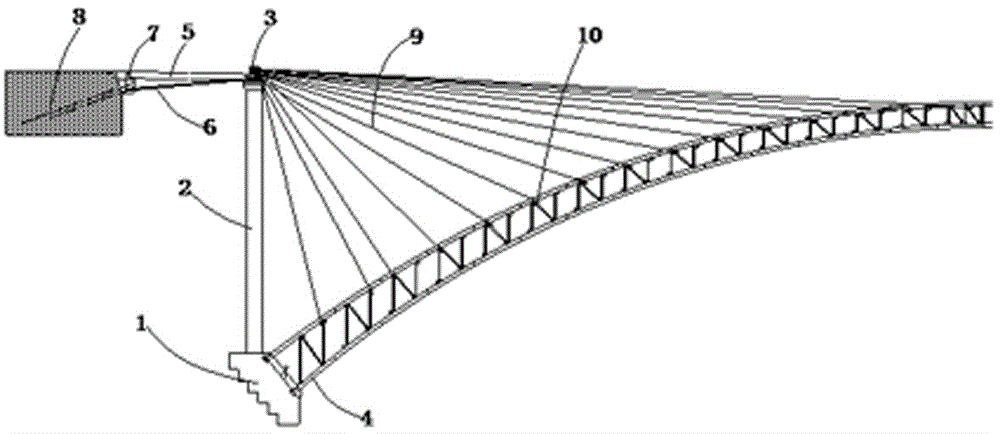

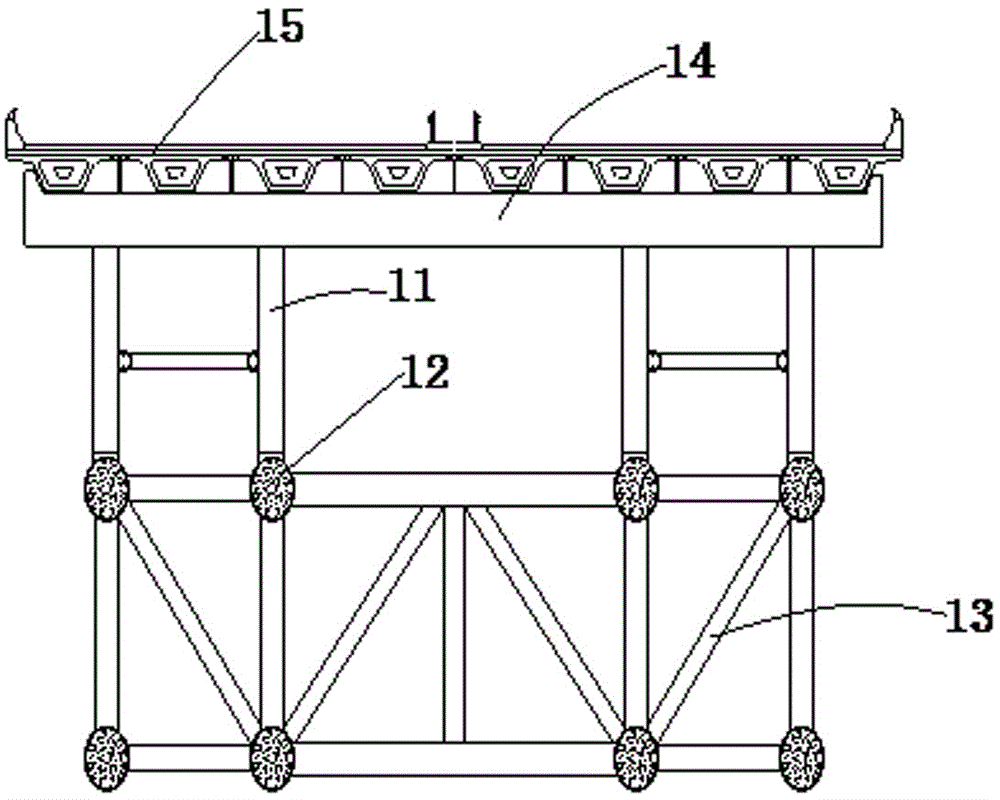

[0036] Such as image 3 As shown, preferably, in the step a, the hoisting system includes a towerless cable crane, which includes a traction cable, a hoisting cable, a chain stay cable system, a hoisting sports car and a corresponding The hoist is convenient for transporting the steel pipe arch rib 4 and the bridge deck 15 and the like. During construction, the steel pipe arch rib 4 is hoisted at first, and then the arch upper column 11 is installed on the upper surface of the steel pipe arch rib 4, and the top of the arch upper column 11 is connected with a steel box cover beam 14. A bridge deck 15 is installed on the top of the box cover girder 14 .

Embodiment 3

[0038] As a preference, in the step b, when assembling the nth segment steel pipe arch rib 4, install the lower chord and the cross-link members between them, the middle lower cross brace and the web; two adjacent webs are temporarily connected Fix, pull the cable wind or add support to prevent it from toppling; then install the diagonal brace of the steel pipe arch rib 4 of the nth section, and bolt the gusset plate connected with the upper chord to the upper end of the diagonal brace; place the steel pipe arch rib 4 of the nth section The upper chords of the ribs 4 and the cross-link members between them are assembled on the bridge deck between the two steel pipe arch ribs 4, and then installed in the designed position.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com