How to install a condensing steam turbine

An installation method and steam turbine technology, applied to mechanical equipment, engine components, machines/engines, etc., can solve the problems of low installation accuracy adjustment efficiency, rework, etc., and achieve the effect of eliminating rework, ensuring the installation period, and ensuring clearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention is further illustrated below by specific examples.

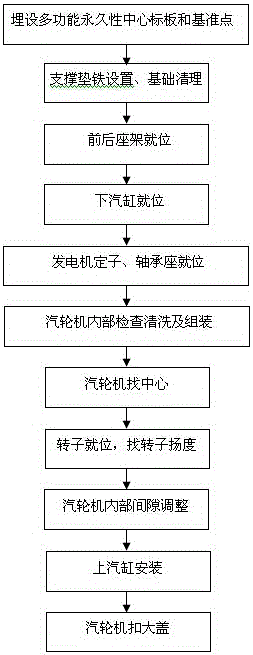

[0047] Such as figure 1 as shown in figure 1As shown, the installation method of the condensing steam turbine includes the following steps:

[0048] Step 1. Embedding the multi-functional permanent center mark and reference point: effectively preventing the hidden danger of in-situ rotation and movement of the center mark and reference point after they are buried. Therefore, the measurement error caused by the measurement standard is reduced, and the accuracy of the measurement standard is ensured. It can realize the minimization of datum measurement error caused by embedding of datum point and central target plate.

[0049] Step 2. In the setting of supporting shims and foundation cleaning, the multi-point support fine-tuning method is used to adjust the steam turbine. It is necessary to arrange the shims according to the layout of the anchor bolts in the drawing. A set of shims is set on bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com