Design and manufacturing method of special hot-water boiler for burning hot gas of generator

A technology for hot water boilers and manufacturing methods, applied to lighting and heating equipment, water heaters, fluid heaters, etc., can solve the problems of large pollutant discharge, dispersion, and lack of conventional gas sources, etc., to achieve sufficient combustion and reduce The effect of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

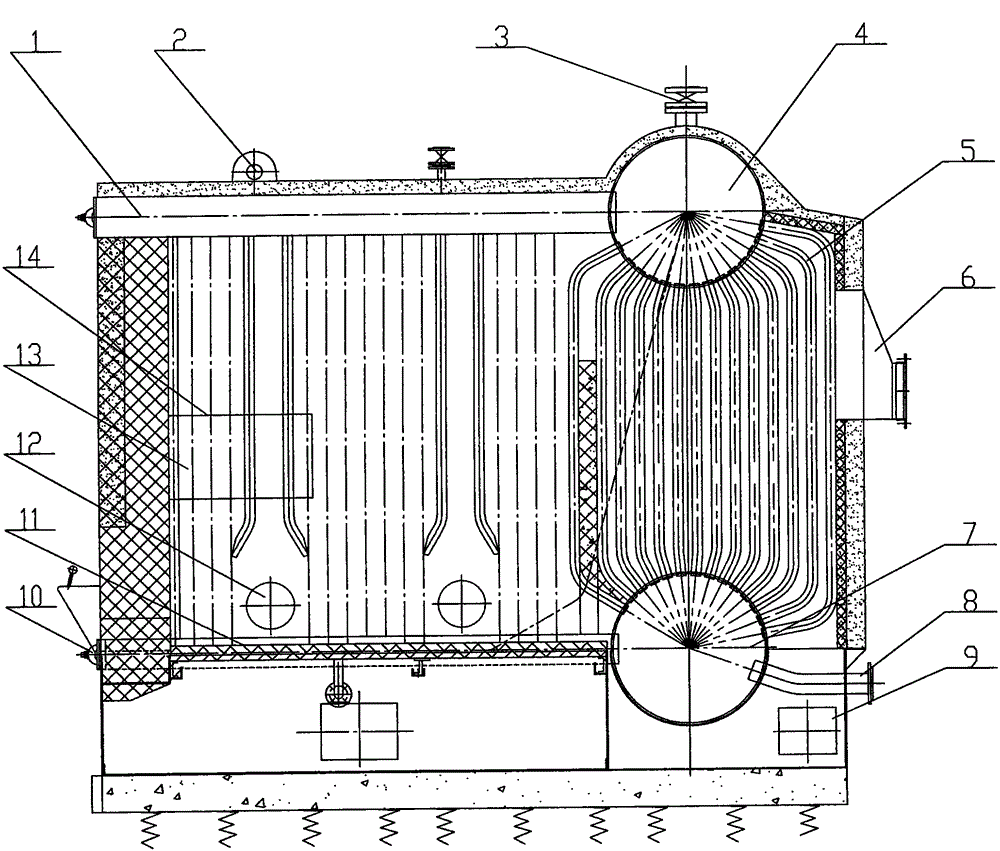

[0030] Attached figure 1 One end of the header tube (1) on the furnace shown in the furnace is perforated and inserted into the drum (4), the upper end of the convection tube bundle (5) is bent and inserted into the upper drum (4), and the convection tube bundle (5) ) is bent and inserted into the lower drum (7) for welding, the upper heads of the water-cooled wall tubes (13) on both sides of the furnace are punched and welded with the upper header (1) of the furnace, and the lower heads are respectively connected with the left and right lower headers figure 2 The middle (15, 25) is perforated and inserted into welding, and the water wall tube (13) on the right side and the lower header figure 2 The top of middle (25) leaves burner installation hole (12) and leaves secondary burner installation hole (14) in the left side middle lower part of left side water-cooled wall pipe (13).

Embodiment 2

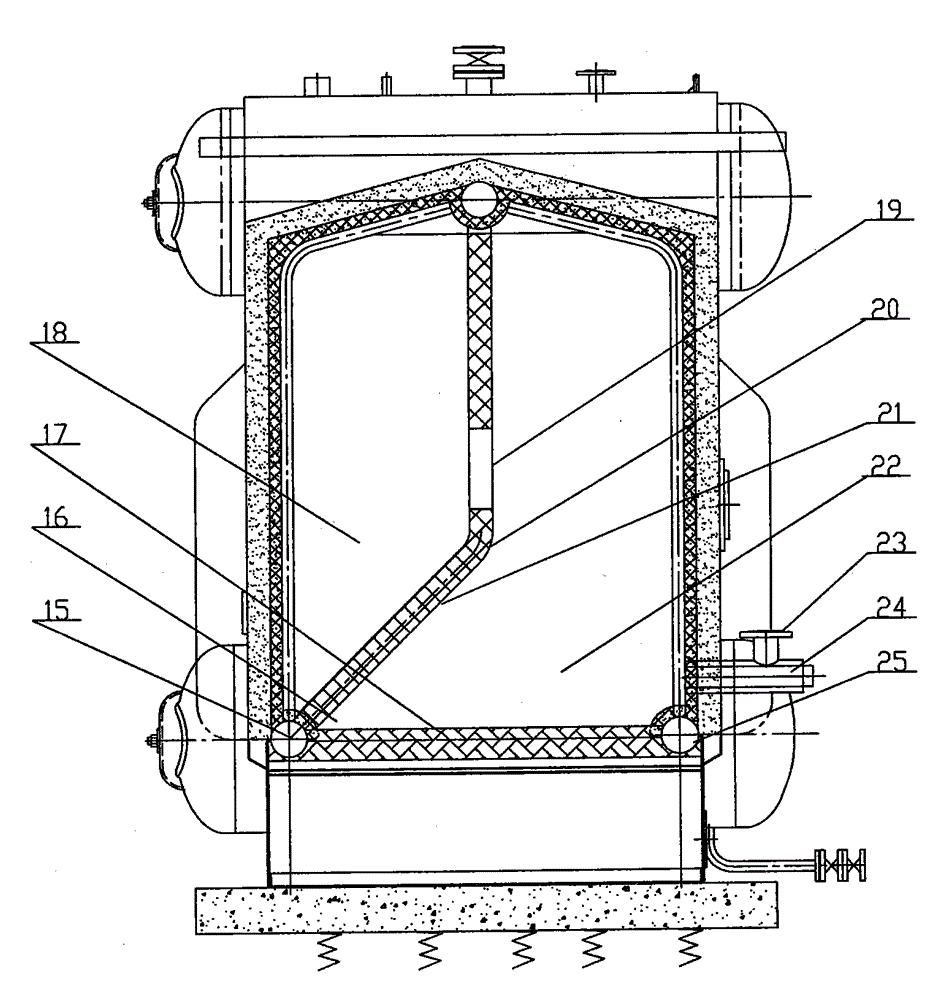

[0032] with attached figure 2 The upper head of the water-cooled wall pipe (20) in the middle of the shown furnace and the upper header of the furnace figure 1 (1) is perforated and inserted into welding, bent at 1 / 3 of the middle and lower end, the lower head and the left lower header (15) are perforated and inserted into welding, and the entire furnace is divided into two to form two combustion chambers (22 , 18), an alpha angle (16) is formed at the connection point between the lower end of the middle water wall tube (20) and the left lower header (15) and the surface of the furnace bottom (17) heat storage radiation layer, the hypotenuse of the alpha angle Constitute the flame refraction arch (21) of the main combustion chamber.

[0033] There is a high-temperature flue gas channel (19) above the 1 / 3 bend of the middle water wall tube (20), when the combustible gas enters the combustion nozzle (24) and the primary air (23) is mixed at the combustion nozzle mouth , the c...

Embodiment 3

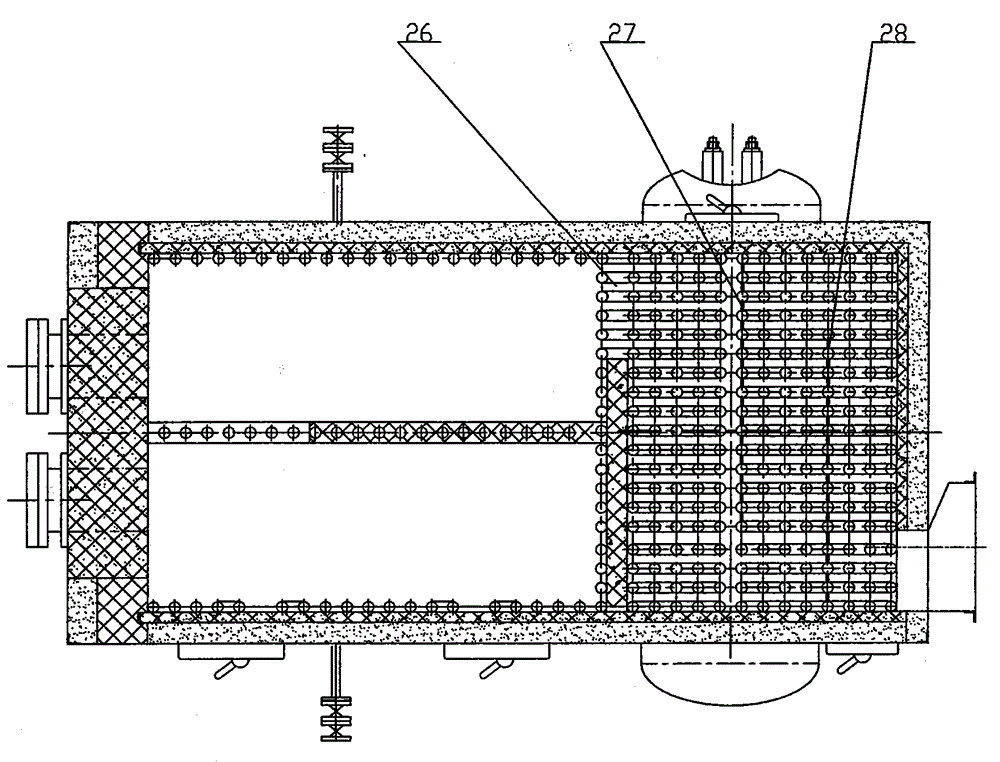

[0035] with attached image 3 As shown, after the secondary combustion chamber figure 2 The high-temperature flue gas after secondary combustion in (18) enters through the exhaust channel (26) figure 1 The middle convection tube bundle (5) is provided with two smoke baffles (27, 28) in the middle of the convection tube bundle (5). After a return convective heat exchange, the figure 1 The middle smoke outlet (6) is discharged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com