Coal feeder type coal quality composition online analysis device and analysis method

An analysis device and coal feeder technology, which is applied in the direction of measuring devices, analysis materials, instruments, etc., can solve the problems of large compositional analysis errors, low spectral resolution accuracy, and adjustment in the coal industry, so as to avoid unplanned shutdown and improve boiler efficiency , The effect of excellent spectrum resolution accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

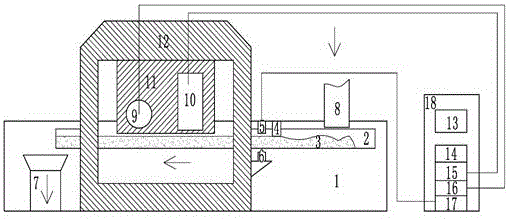

[0019] Coal feeder-type coal quality composition online analysis device, please refer to the attached figure 1 , mainly including a coal feeding system, a detection system and a control system; the coal feeding system sequentially includes a coal feeder (1), a drop pipe (8), a U-shaped small belt (2), a shaper (4) and a discharge tube (7); the detection system includes a microwave receiver (5), a microwave transmitter (6) and a protective body (12) in sequence; a D-T neutron generator (9) is arranged on the upper side of the protective body (12) and BGO detector (10), D-T neutron generator (9) and BGO detector (10) are placed in lead block (11); the control system includes digital control neutron generator unit (16), spectrum acquisition and a control unit (15), a microwave data central processing unit (17), a computer data processing unit (14) and a display unit (13); the microwave transmitter (6) and the microwave receiver (5) are connected to the microwave data central proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com