Touch panel and manufacturing method thereof

A technology of touch panel and touch electrode, which is applied in the direction of instruments, electrical digital data processing, and input/output process of data processing, etc., and can solve problems such as being easily scratched or oxidized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The touch panel and its manufacturing method will be further described below in conjunction with the accompanying drawings and specific embodiments.

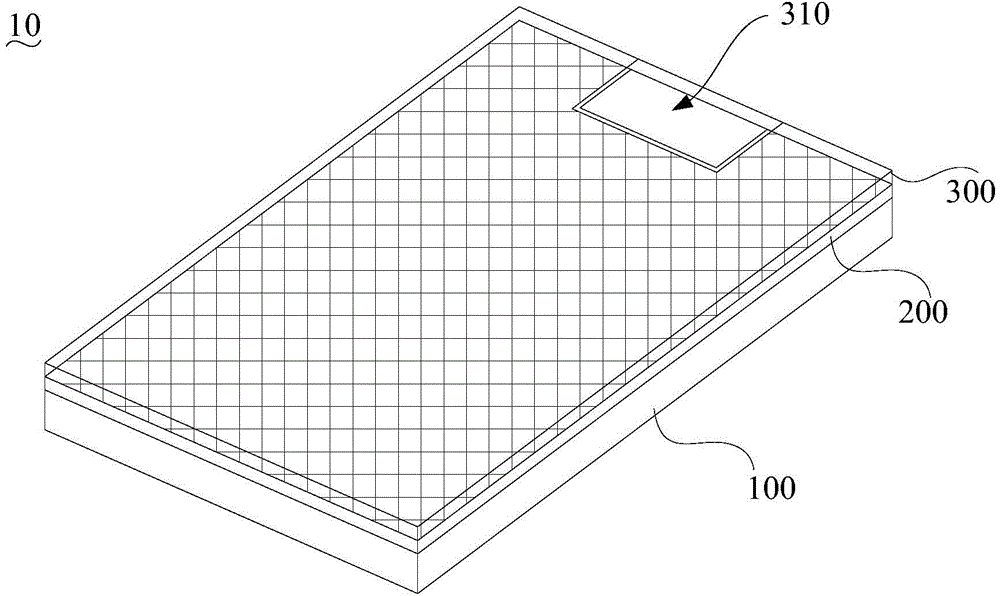

[0051] Such as figure 1 As shown, the touch panel 10 according to one embodiment includes a transparent substrate 100 , a conductive layer 200 and a first transparent photosensitive resin layer 300 .

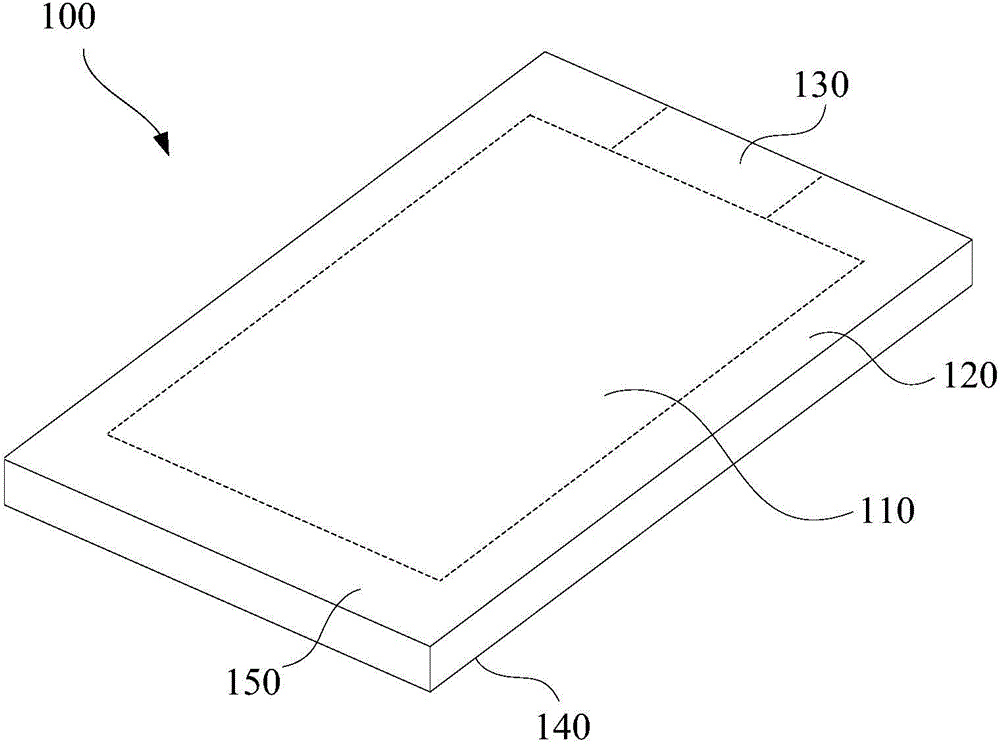

[0052] Such as figure 2 As shown, the transparent substrate 100 has a visible area 110 and a non-visible area 120, and the non-visible area 120 is provided with a binding area 130 for binding with a flexible circuit board.

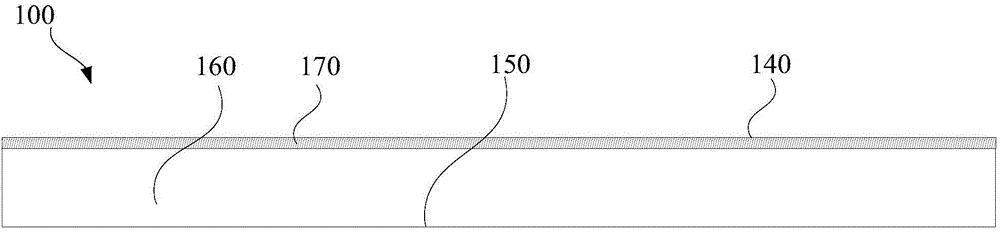

[0053] The touch panel 10 needs to have a protective cover. In this embodiment, the transparent substrate 100 is also the protective cover of the touch panel 10 . That is, the transparent substrate 100 has a touch surface 140 and a bearing surface 150 opposite to each other. Wherein, the surface hardness of the touch surface 140 is greater than or equal to 3H (3H is a pencil hardness level), so tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com