Method for calculating load distribution of composite bolt connection by considering clearance and friction influence

A technology of friction effects and composite materials, applied in calculation, design optimization/simulation, special data processing applications, etc., can solve problems such as difficult establishment of calculation models, and achieve easy clearance and friction effects, high calculation efficiency, and rapid establishment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The implementation scheme of the present invention will be specifically described below in conjunction with the accompanying drawings.

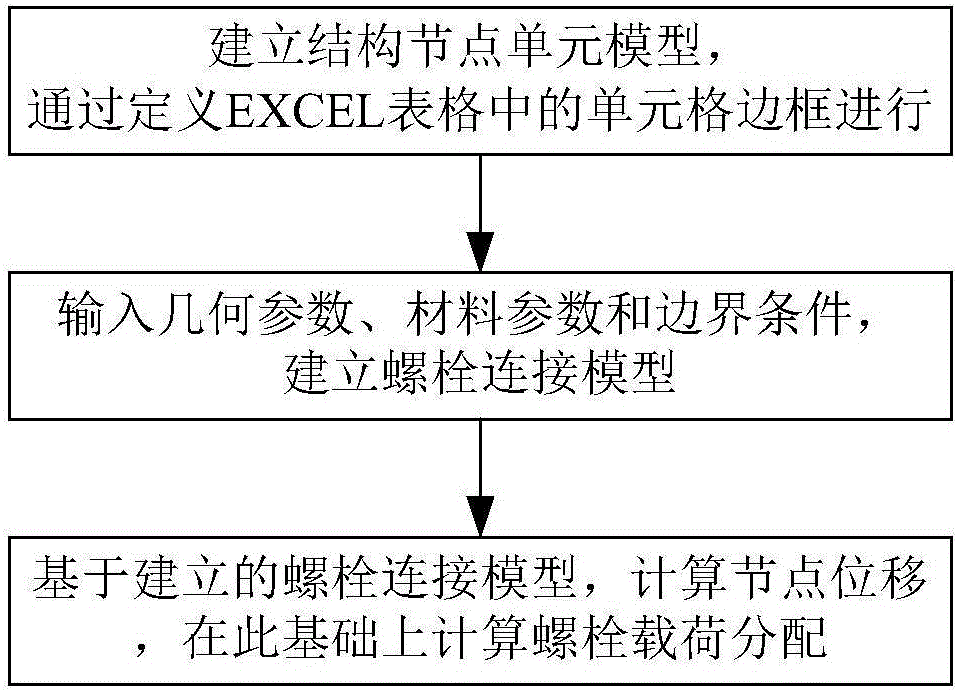

[0024] The calculation method for calculating the load distribution of the composite material bolt connection considering the influence of the gap and the friction provided by the invention is based on the spring model and the finite element method, realizes the fast establishment of the calculation model of the bolt connection, and calculates the distribution of the bolt load on this basis. The overall steps of the method of the present invention are as follows figure 1 As shown, each step is described in detail below.

[0025] Step 1. Establish structural node element model. Structural modeling is performed by defining cell borders in EXCEL tables.

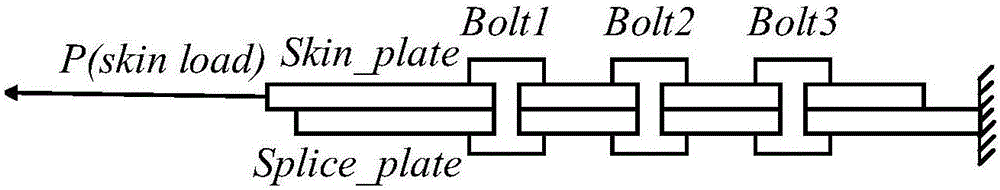

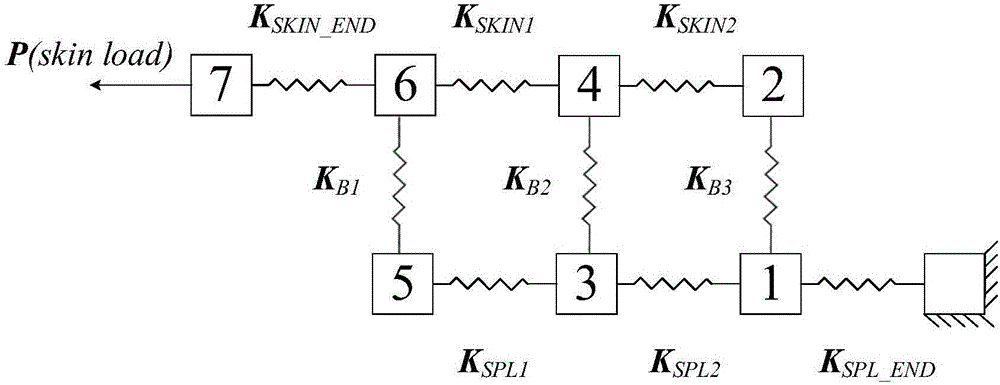

[0026] If for figure 2 The equivalent spring model of the three-bolt single-shear lap joint structure shown is as follows: image 3 shown. figure 2 Among them, Skin_plate represen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com