Reinforcement detailing-modularized machining system and method based on BIM (Building Information Modeling) technology

A processing system and modular technology, applied in the direction of manufacturing computing systems, computing, computer parts, etc., can solve the problems of heavy workload and low computing efficiency, achieve high accuracy, strong social benefits, and eliminate deviations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

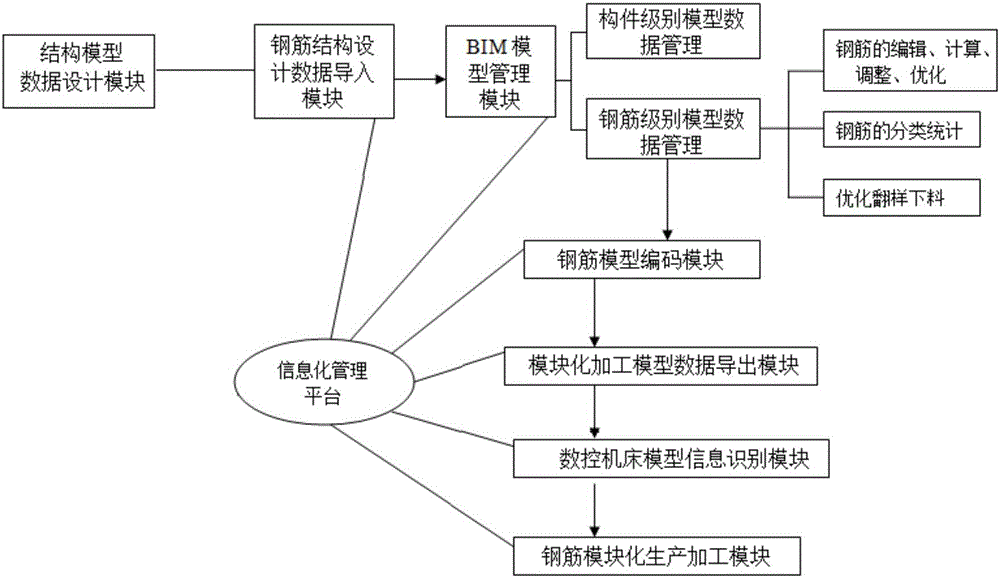

[0037] Example: A BIM technology-based steel bar sample calculation-modular processing system, including a structural model data design module, a steel structure design data import module, a BIM model management module, a steel bar model coding module, and a modular processing model data export module , CNC machine tool model information recognition module, steel bar modular production and processing module and information management platform; said steel bar structure design data import module, BIM model management module, steel bar model coding module, modular processing model data export module, CNC machine tool model Both the information recognition module and the steel bar modular production and processing module can realize end-to-end data transfer with the information management platform;

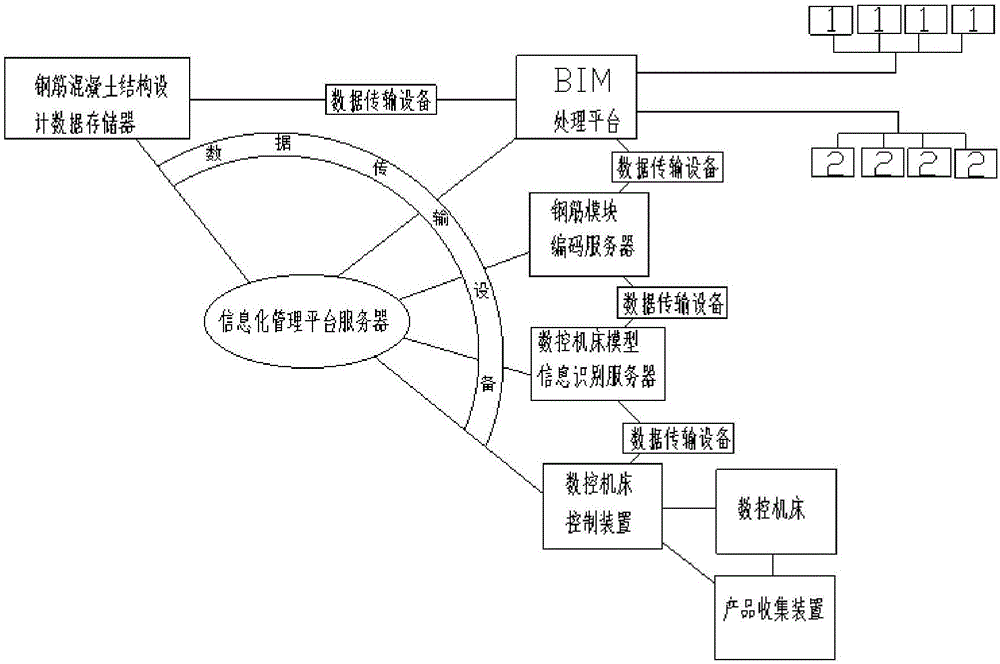

[0038] The physical devices that carry the system include reinforced concrete structure design data storage, BIM processing platform, steel bar module encoding server, CNC machine tool in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com