Graphene cable line as well as preparation method and wiring method thereof

A cable and graphene technology, which is applied in the direction of cable/conductor manufacturing, insulated cables, power cables, etc., can solve the problems of general conduction and anti-aging effects, large power loss, and heavy tower loads. It is not easy to achieve The effect of breaking or breaking, increased friction, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

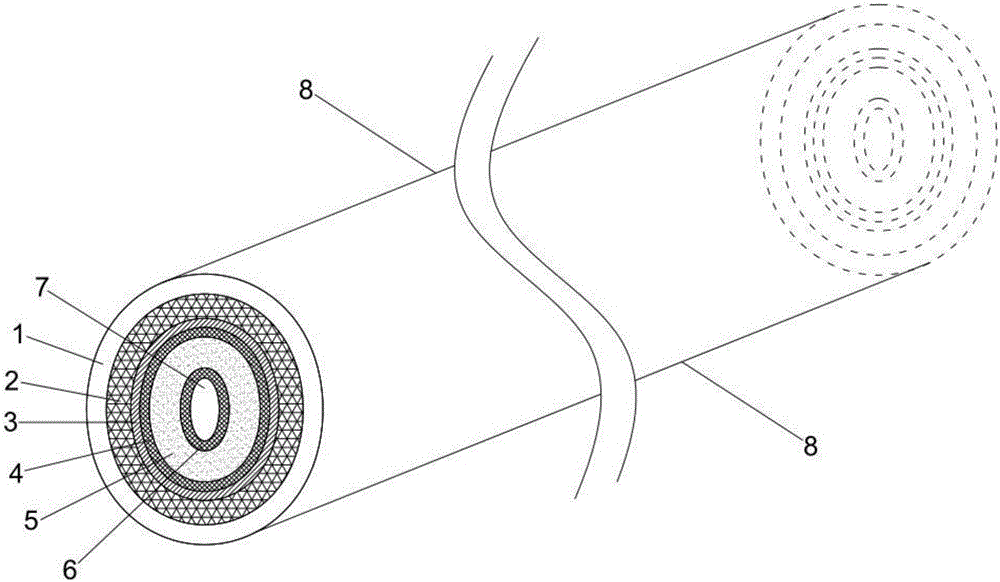

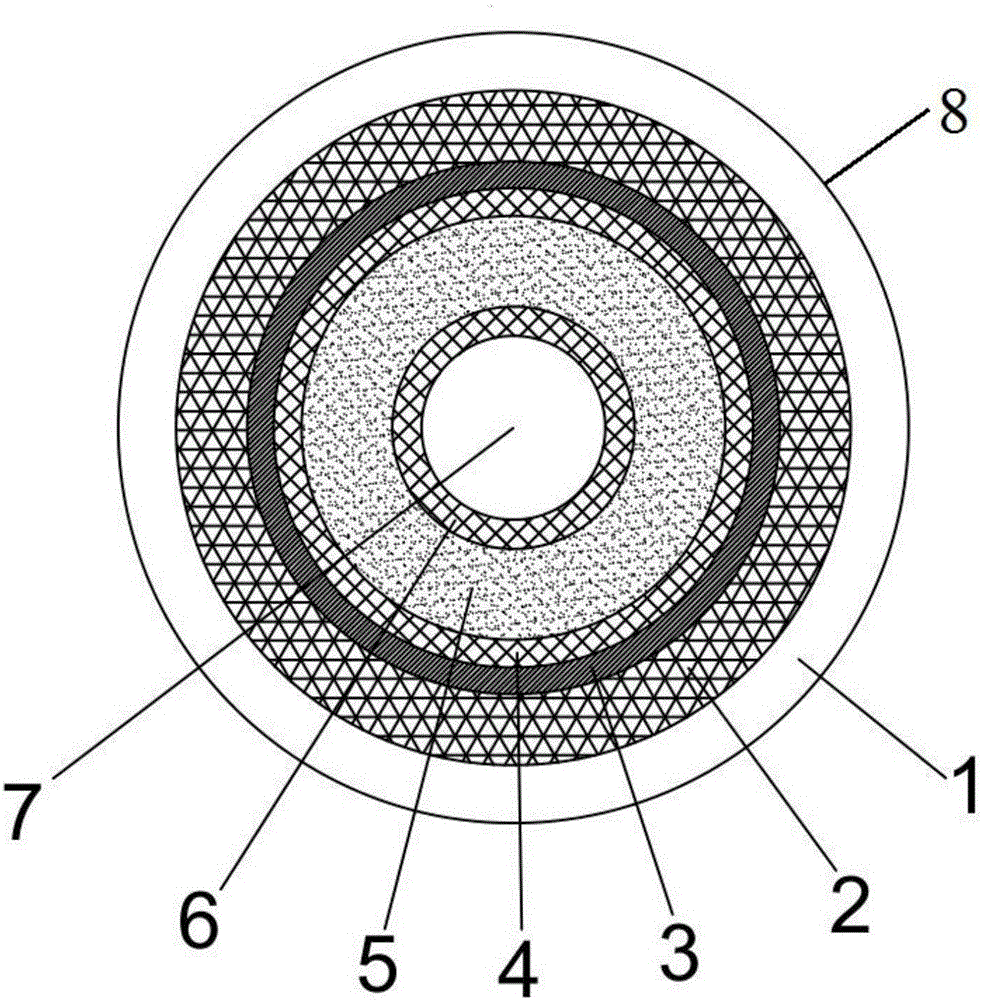

[0042] Such as figure 1 and figure 2 As shown, the technical solution of the present invention to solve the above-mentioned technical problems is as follows: a graphene cable, including a seven-layer structure that is sequentially fitted, and the seven-layer structure is sequentially from the outside to the inside of a rubber layer 1, a plastic layer 2, and an insulating adhesive tape Layer 3, first pure cotton gauze layer 4, graphene layer 5, second pure cotton gauze layer 6 and steel wire layer 7.

[0043] Further: the rubber layer 1 and the plastic layer 2 are made by processing rubber granules and insulating plastic granules respectively.

[0044] The thickness of the insulating tape layer 3 is 1 mm to 2 mm, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com