Organic light-emitting display device and manufacturing method thereof

A light-emitting display and organic technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of not being able to satisfy electrical properties at the same time, and achieve the effect of rapid opening and closing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

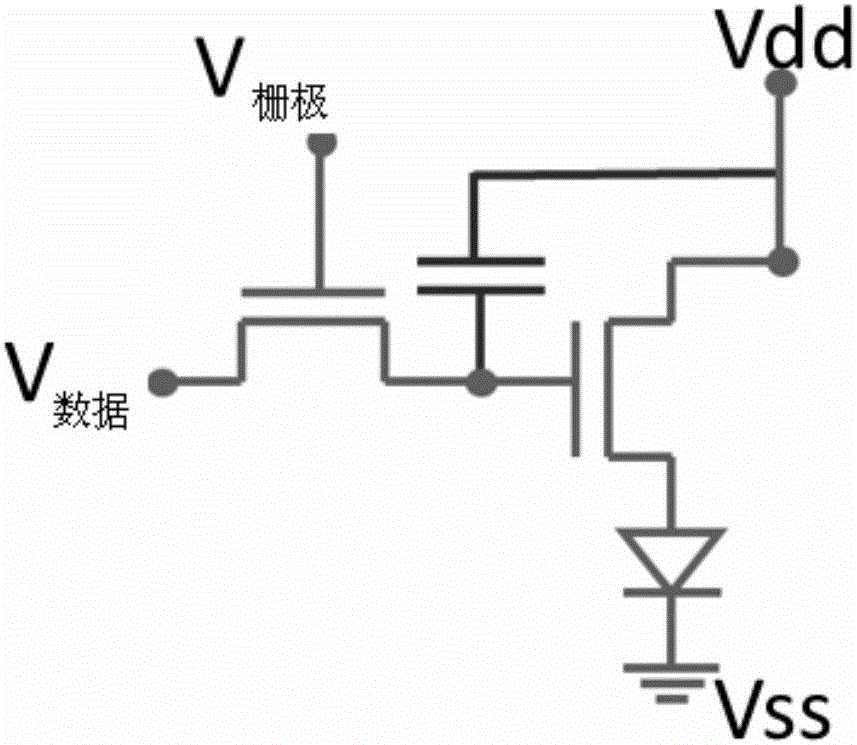

[0041] Figure 4 A schematic cross-sectional structure diagram of an organic light-emitting display device according to an embodiment of the present invention is shown. Such as Figure 4 As shown, the organic light emitting display device of this embodiment includes a switching TFT T1, a driving TFT T2, and a storage capacitor connected to the switching TFT T1 and the driving T2 respectively.

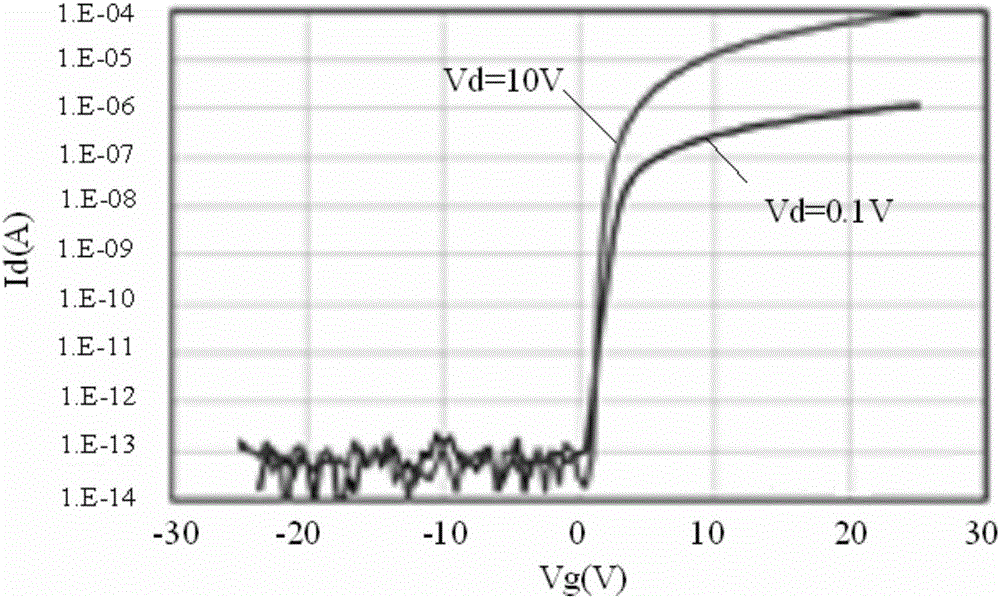

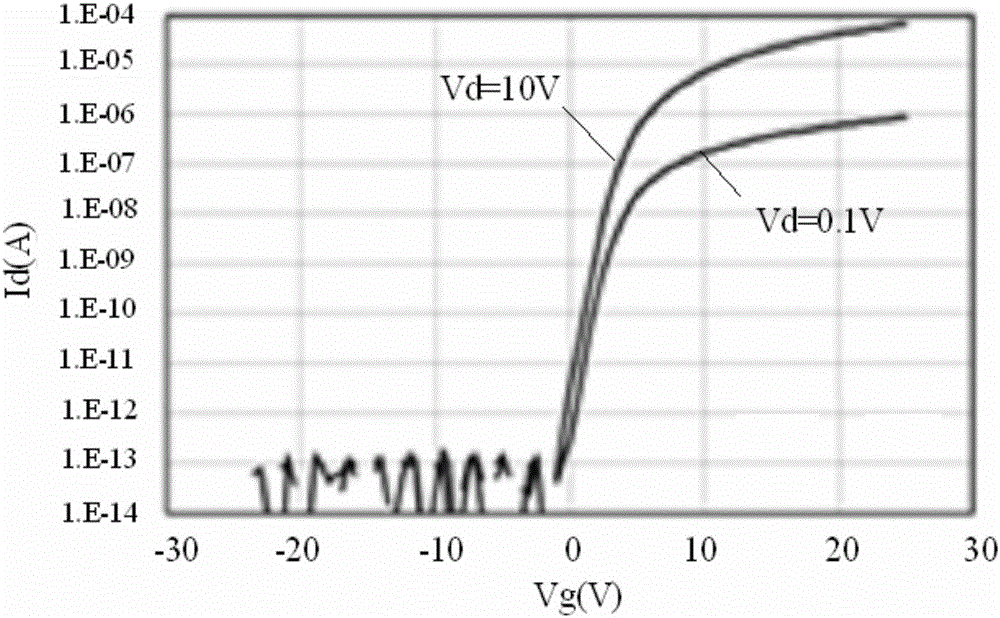

[0042] Specifically, the switching TFT T1 has a first active layer 9 for reducing the sub-threshold swing of the transfer characteristic curve of the switching TFT T1. Furthermore, the driving thin film field effect transistor T2 has a second active layer 10 for increasing the sub-threshold swing of the transfer characteristic curve of the driving thin film field effect transistor T2.

[0043] The first active layer 9 can make the sub-threshold swing of the transfer characteristic curve of the switching thin film field effect transistor T1 smaller, so that the switching thin film fiel...

Embodiment 2

[0046] The organic light-emitting display device of this embodiment includes a switching TFT T1, a driving TFT T2, and storage capacitors respectively connected to the switching TFT T1 and the driving T2.

[0047] Specifically, the switching TFT T1 has a first active layer 9 for reducing the sub-threshold swing of the transfer characteristic curve of the switching TFT T1. Furthermore, the driving thin film field effect transistor T2 has a second active layer 10 for increasing the sub-threshold swing of the transfer characteristic curve of the driving thin film field effect transistor T2.

[0048] Compared with Embodiment 1, the oxygen content of the second active layer 10 of the organic light emitting display device of this embodiment is higher than the oxygen content of the first active layer 9 . The oxygen content of the first active layer 9 determines the subthreshold swing of the transfer characteristic curve of the switching thin film field effect transistor T1, and the o...

Embodiment 3

[0051] The organic light-emitting display device of this embodiment includes a switching TFT T1, a driving TFT T2, and storage capacitors respectively connected to the switching TFT T1 and the driving T2.

[0052] Specifically, the switching TFT T1 has a first active layer 9 for reducing the sub-threshold swing of the transfer characteristic curve of the switching TFT T1. Furthermore, the driving thin film field effect transistor T2 has a second active layer 10 for increasing the sub-threshold swing of the transfer characteristic curve of the driving thin film field effect transistor T2. Wherein, the oxygen content of the second active layer 10 is higher than that of the first active layer 9 .

[0053] Compared with Embodiment 2, both the first active layer 9 and the second active layer 10 of the organic light emitting display device of this embodiment are InGaZnO compound layers.

[0054] The active layer requires high mobility of materials, but traditional amorphous silicon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com