Work method of high-voltage frequency converter capable of automatic fire extinguishment

A technology of high-voltage frequency converter and working method, which is applied in the field of electric power, can solve problems such as internal circuit short circuit of high-voltage frequency converter, lack of automatic detection, potential safety hazards, etc., and achieve the effects of long service life, wide application range and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

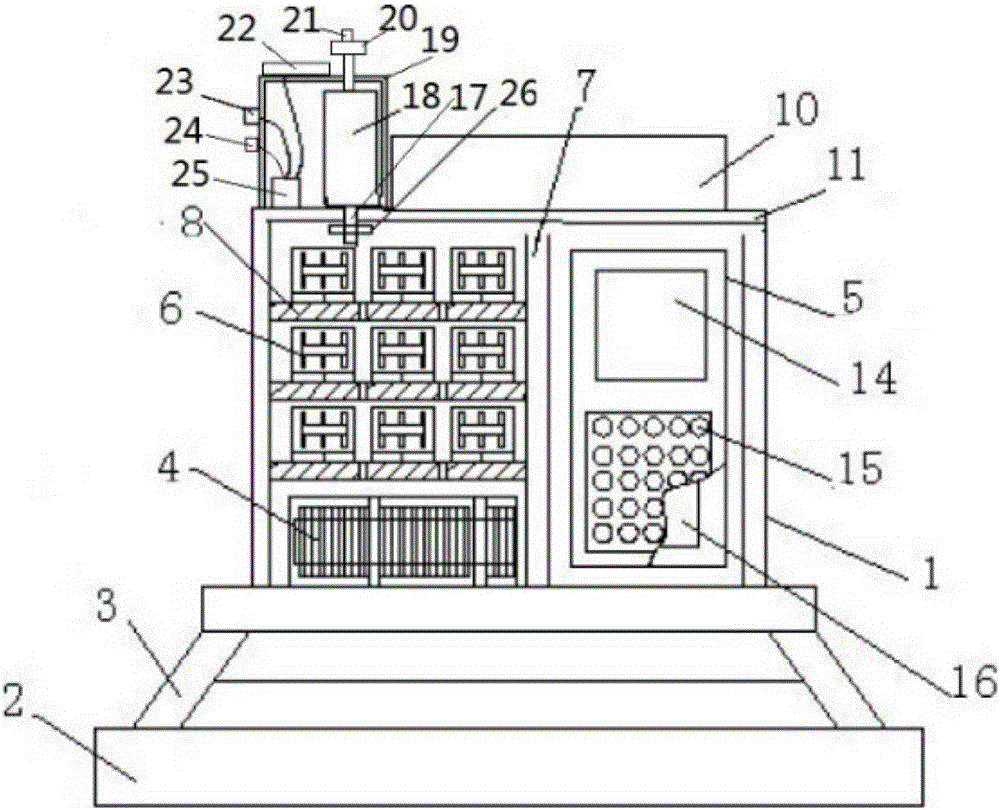

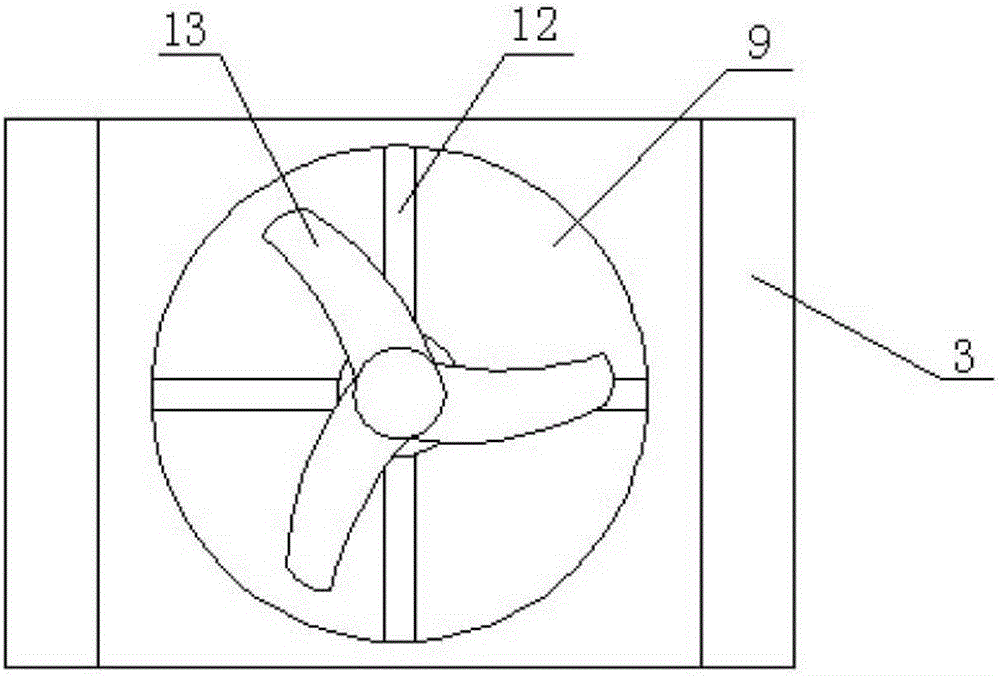

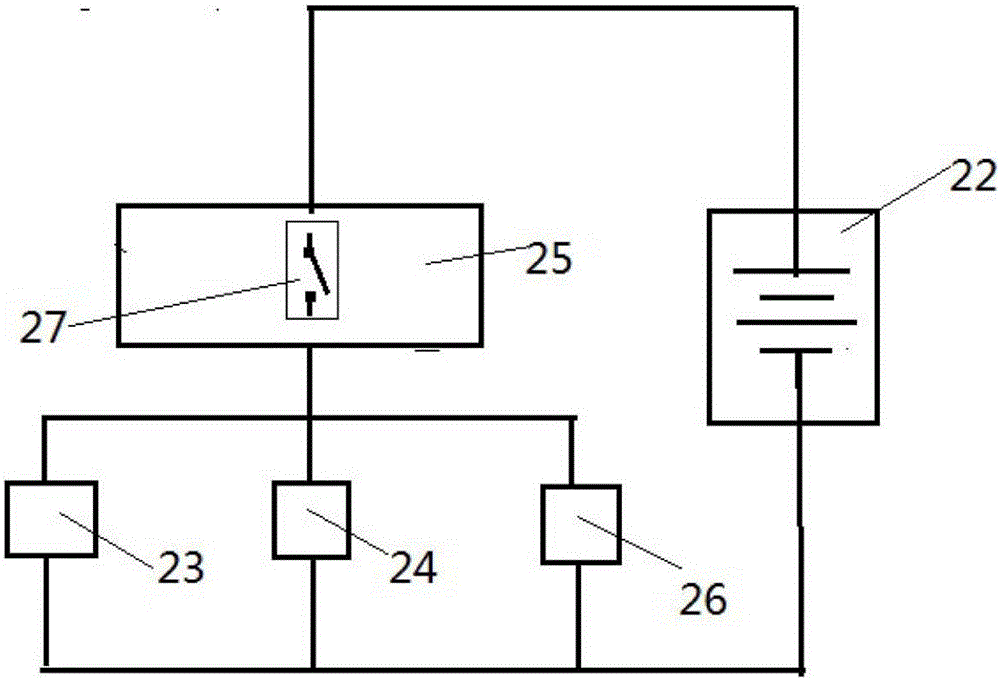

[0018] refer to figure 1 and figure 2 A high-voltage frequency converter shown includes a high-voltage frequency converter body 1, a base 2 and a support base 3, an iron core transformer 4 disposed in the high-voltage frequency converter body 1, and a control box disposed in the high-voltage frequency converter body 1 5, and the power unit 6 arranged in the high-voltage inverter body 1, the support base 3 is installed on the base 2, the high-voltage inverter body 1 is installed on the support base 3, and the high-voltage inverter body 1 is equipped with There is a vertical partition 7, and the high-voltage inverter body 1 on the left side of the vertical partition 7 is provided with three horizontal partitions 8, the control box 5 is installed on the right side of the vertical partition 7, and the power unit 6 is installed on the On the three transverse partitions 8 , the iron core transformer 4 is mounted on the inner bottom of the high voltage frequency converter body 1 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com