A loudspeaker structure

A loudspeaker and basin frame technology, which is applied in the field of loudspeaker structure, can solve the problems of abnormal sound, elastic waves are easy to hit the screw head, and the screw hole is difficult to manufacture. , the effect of good music enjoyment experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

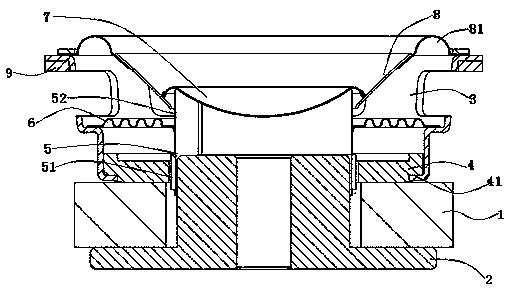

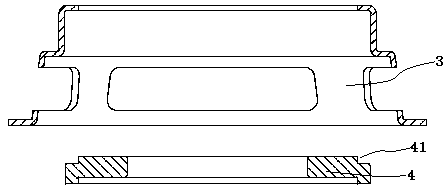

[0022] Such as Figure 1 ~ Figure 4 As shown, a new type of loudspeaker structure, including magnet 1, T iron 2, basin frame 3, washer 4, voice coil 5, elastic wave 6, dust cap 7, drum paper 8 and gasket 9, drum paper 8 is set There is a ring 81, the gasket 9 is located below the outer edge of the basin frame 3, the magnet 1 is located above the T iron 2, and a magnetic gap is formed between the washer 4 and the T iron 2, so The voice coil 5 is arranged in the magnetic gap, and the voice coil 5 includes a voice coil wire part 51 and a voice coil tube part 52; The outer side of the washer 4 is provided with a riveting groove 41 , and the washer 4 is riveted and fixed with the basin frame 3 through the riveting groove 41 . Compared with the two methods of fixing the washer and the pot frame by riveting joints and screw fixing, the new loudspeaker structure of the present invention stamps the outer side of the washer 4 by using a mold, so that the riveting groove 41 of the washe...

Embodiment 2

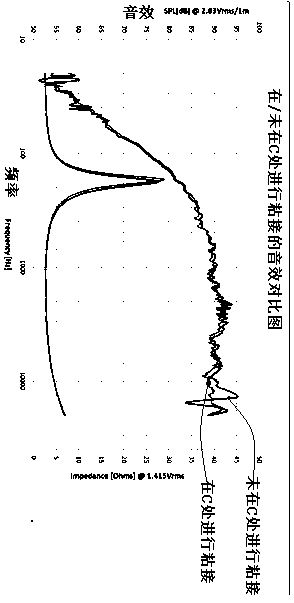

[0025] Traditionally, the voice coil tube portion 52 of the voice coil 5 is bonded and fixed to the dust cap 7 and the drum paper 8 during production of the speaker. Such as Figure 5 As shown, except the joint A between the voice coil tube part 52 and the dustproof cap 7 and the joint B between the voice coil tube part 52 and the drum paper 8, the new loudspeaker structure of the present invention is at the joint between the dustproof cap 7 and the drum paper 8 Gluing process is added to the joint C, and the dustproof cap 7 and the drum paper 8 are bonded together. Such as Figure 6 As shown, in the frequency range of 8000-20KHz, the curve response is smoother, the high-frequency hearing is more stable and smooth, and the glitch caused by the large fluctuation of the peak and valley of the curve is eliminated, and a good music enjoyment experience can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com