Production process of bentonite crushed cat litter and manufacturing equipment thereof

A production process and technology of bentonite are applied in the production process of bentonite crushed cat litter and the field of manufacturing equipment thereof, and can solve the problems of large percentage of impurities, general water absorption effect of cat litter, low utilization rate of raw materials, etc., and achieve less impurities and water absorption. The effect of good performance and consumption saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

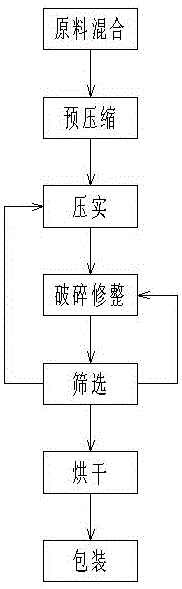

[0020] The specific steps of the production process are as follows: raw materials are mixed, bentonite powder and additives are poured into a mixing tank, and mixed evenly; pre-compression, the mixed materials are sent to the screw feeder, the raw materials are pre-compressed; compaction, The pre-compressed raw material is pressed into the middle of the two pairs of relatively rotating rollers for compaction; crushed and trimmed, the compacted sheet is automatically degrooved into the crusher, crushed into particles, and enters the granulator for processing Trimming; screening, the trimmed particles are squeezed out through the sieve plate into the screening machine, and different treatments are carried out according to the particle size. The granular bentonite cat litter produced by this process has good water absorption, strong hardness, and good agglomeration performance. It has less impurities, low ash content, and can be used as cat litter with less consumption.

[0021] In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com