A kind of microcrystalline enzyme type facial cleanser and preparation method thereof

The technology of facial cleanser and enzyme is applied in the field of daily chemicals, which can solve the problems of high skin irritation, dry skin, high price, etc., and achieves the effects of mild preparation conditions, simple and easy preparation method, and good moisturizing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

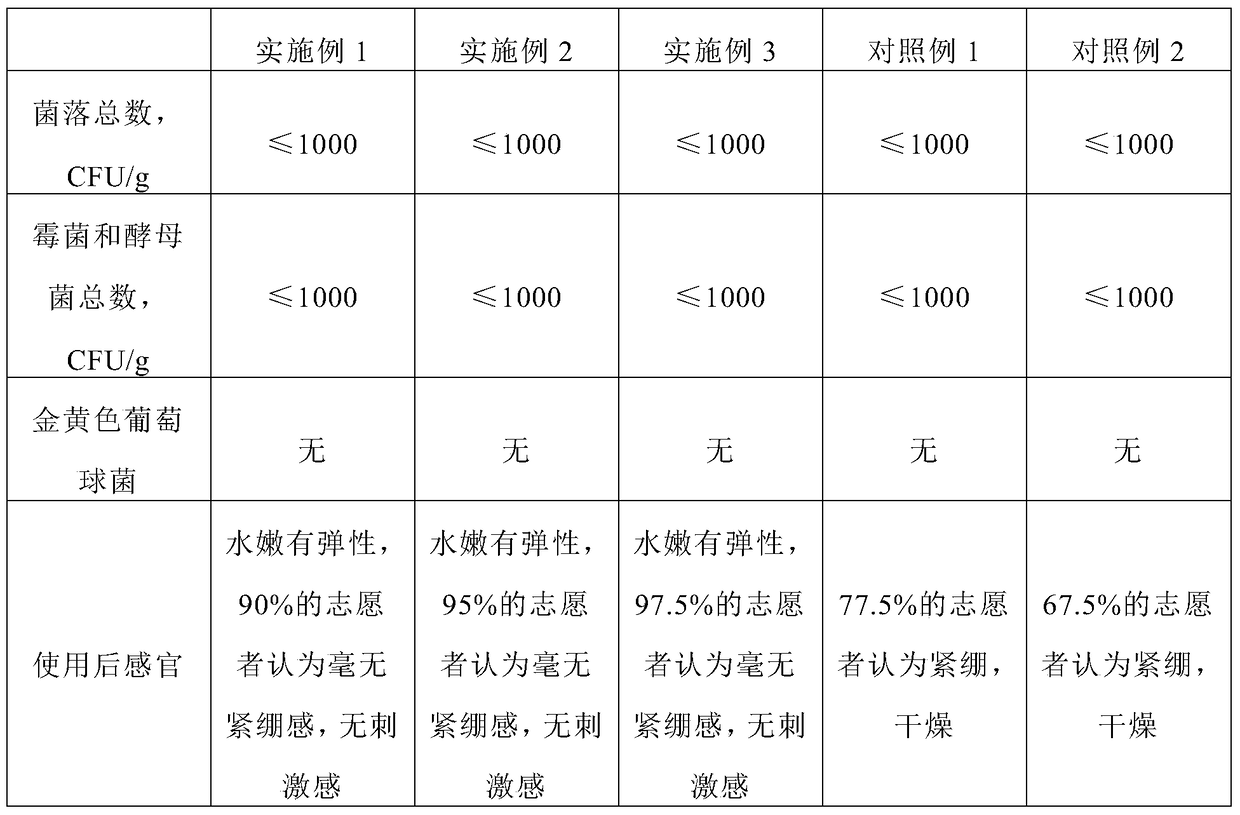

Examples

Embodiment 1

[0017] Microcrystalline enzyme facial cleanser, comprising the following components in parts by mass: 2 parts of isopropyl myristate, 10 parts of glycerin, 3 parts of sodium methyl lauroyl taurate, 6 parts of tocopheryl acetate, 2 parts of aluminum magnesium silicate, 10 parts of 1,3-propanediol, 4 parts of methyl cellulose, 3 parts of jojoba oil, 1 part of microcrystalline enzyme, 59 parts of water.

Embodiment 2

[0019] Microcrystalline enzyme-type facial cleanser, comprising the following components in parts by mass: 1.5 parts of isopropyl myristate, 9 parts of glycerin, 2.5 parts of sodium methyl lauroyl taurate, 5 parts of tocopheryl acetate, 2.5 parts of aluminum magnesium silicate, 9 parts of 1,3-propanediol, 3 parts of methyl cellulose, 2.5 parts of jojoba oil, 0.5 parts of microcrystalline enzyme, 64.5 parts of water.

Embodiment 3

[0021] Microcrystalline enzyme facial cleanser, comprising the following components in parts by mass: 1 part of isopropyl myristate, 5 parts of glycerin, 2 parts of sodium methyl lauroyl taurate, 4 parts of tocopheryl acetate, 2 parts of aluminum magnesium silicate, 5 parts of 1,3-propanediol, 2 parts of methyl cellulose, 2 parts of jojoba oil, 0.5 parts of microcrystalline enzyme, 76.5 parts of water.

[0022] The preparation method of microcrystalline enzyme type facial cleanser comprises the following steps:

[0023] (1) Add isopropyl myristate, sodium methyl lauroyl taurate, tocopheryl acetate, and jojoba oil into the reaction kettle in turn, add half of the water, heat up to 50-60°C, and stir well ;

[0024] (2) Add glycerin, 1,3-propanediol, magnesium aluminum silicate, and methylcellulose to the remaining water, raise the temperature to 90-95°C, and stir for 2-4 hours to obtain mixture A;

[0025] (3) Cool mixture A to 25°C, add microcrystalline enzyme, and stir evenl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com