Waste gas treatment system of self-cleaning simple ventilation cabinet

A technology of waste gas treatment and fume hood, which is applied in the direction of gas treatment, cleaning methods and utensils, and removal of smoke and dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

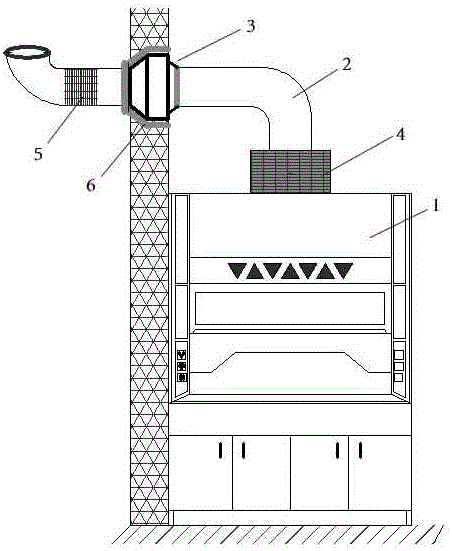

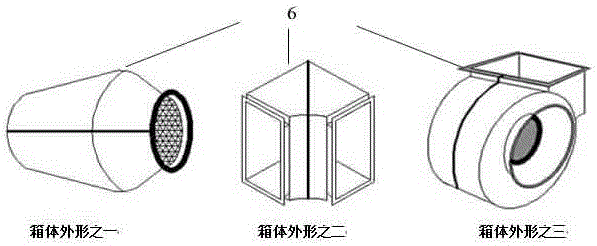

[0012] attached figure 1 , 2 Among them, 1 is the cabinet body of the fume hood, 2 is the ventilation pipe, 3 is the fan, 4 is the front filter, 5 is the rear filter, and 6 is the shockproof and soundproof shielding box.

[0013] As shown in the accompanying drawings, the specific implementation method is: a simple self-cleaning fume hood exhaust gas treatment system, including a fume hood cabinet body 1, consisting of a ventilation pipe 2, a fan 3, a front filter 4, a rear filter 5, The shock-proof and sound-proof shielding box 6 is combined into one, and it is characterized in that the high-temperature, high-humidity, and strong-corrosion exhaust gas discharged from the fume hood is treated for the first time through the front filter 4 set at the suction port of the ventilation pipe 1, and is equipped with a shock-proof and sound-proof The blower fan 3 of the shielding box 6 is drawn out, and then processed for the second time through the rear filter 5 arranged at the outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com