Automatic weighing system for formula materials

An automatic weighing and formula technology, applied in loading/unloading, container, packaging, etc., can solve problems such as unfavorable improvement of industrial capacity improvement requirements, low control precision ability, high labor intensity of employees, etc., to eliminate human subjective factors. Influence, simple structure, manpower saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

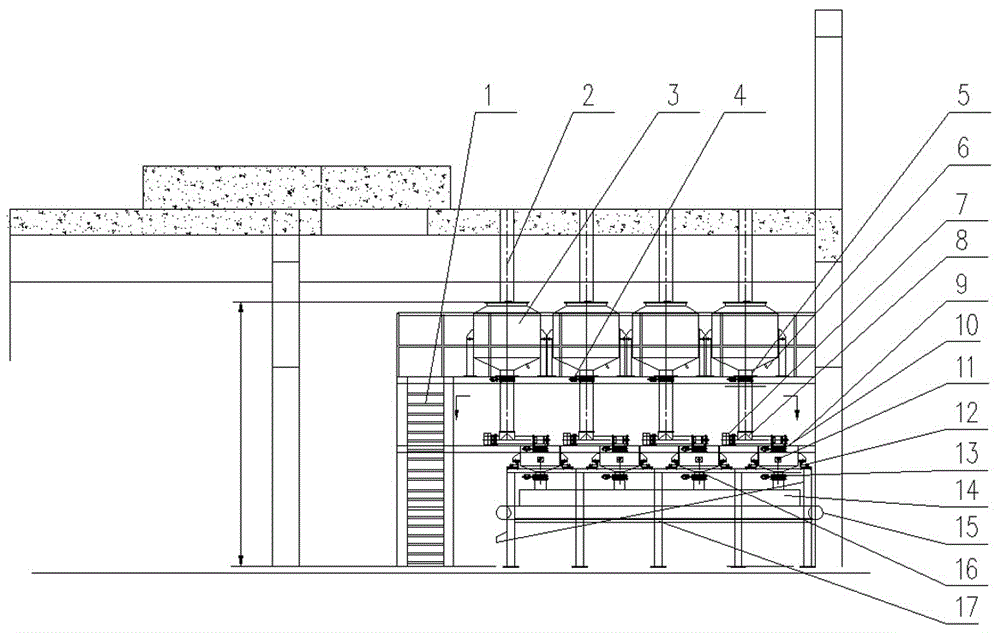

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0023] refer to figure 1 , this embodiment includes a controller (not shown in the figure), a storage tank 3, a screw feeder 7, a weighing hopper 9, a load cell 12 and a mixing bin 14; the storage tank 3 is located in the steel frame structure of the storage tank In the installation hole of the storage tank on 1 (not shown in the figure), the storage tank 3 and the screw feeder 7 are connected through the powder delivery pipe 2, and the feed port 8 of the screw feeder 7 is connected to the powder delivery The pipes 2 are seamlessly connected, and the discharge port of the screw feeder 7 is docked with the feed port 10 of the weighing hopper 9. A conveyor belt 15 is provided below the discharge port 16 of the weighing hopper 9, and the conveyor belt 15 extends into the mixing bin 14.

[0024] The storage tank 3 is composed of three pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com