Mixed flocculent precipitating system of mechanical stirring sedimentation basin

A technology of mechanical stirring and clarification tank, which is applied in the direction of flocculation/sedimentation water/sewage treatment, sedimentation separation, settling tank, etc. It can solve the problems of low processing capacity, high turbidity of effluent water quality, and reduction of large wells, so as to reduce backflow sewage The effect of the amount of mud, the mixing of chemicals and the increase of sedimentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing.

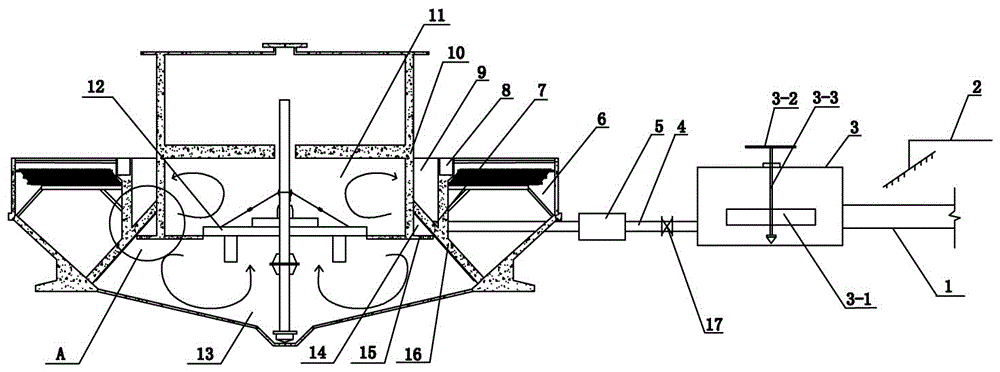

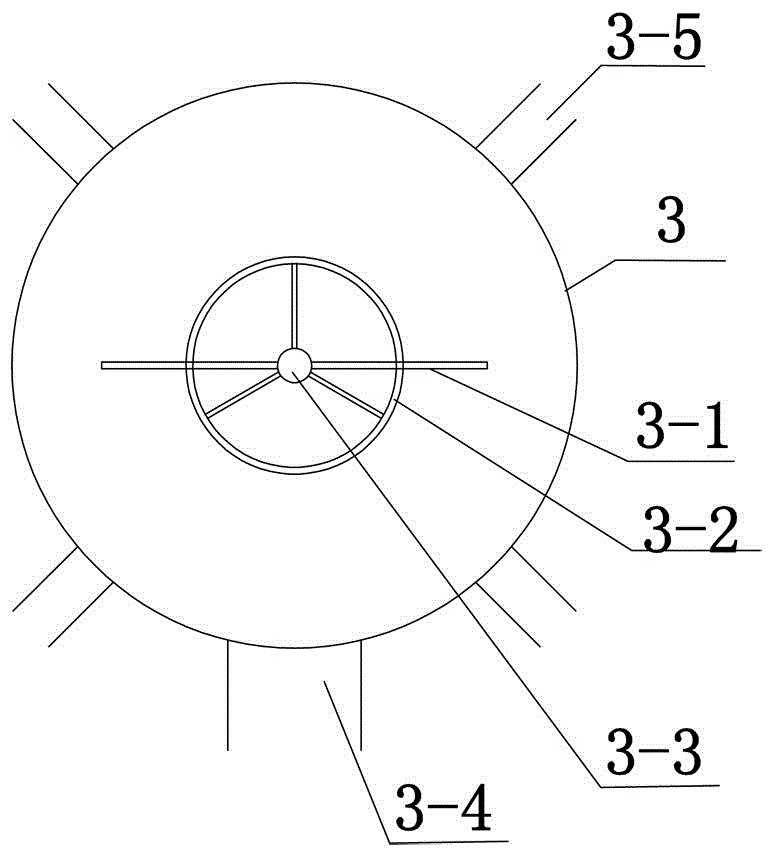

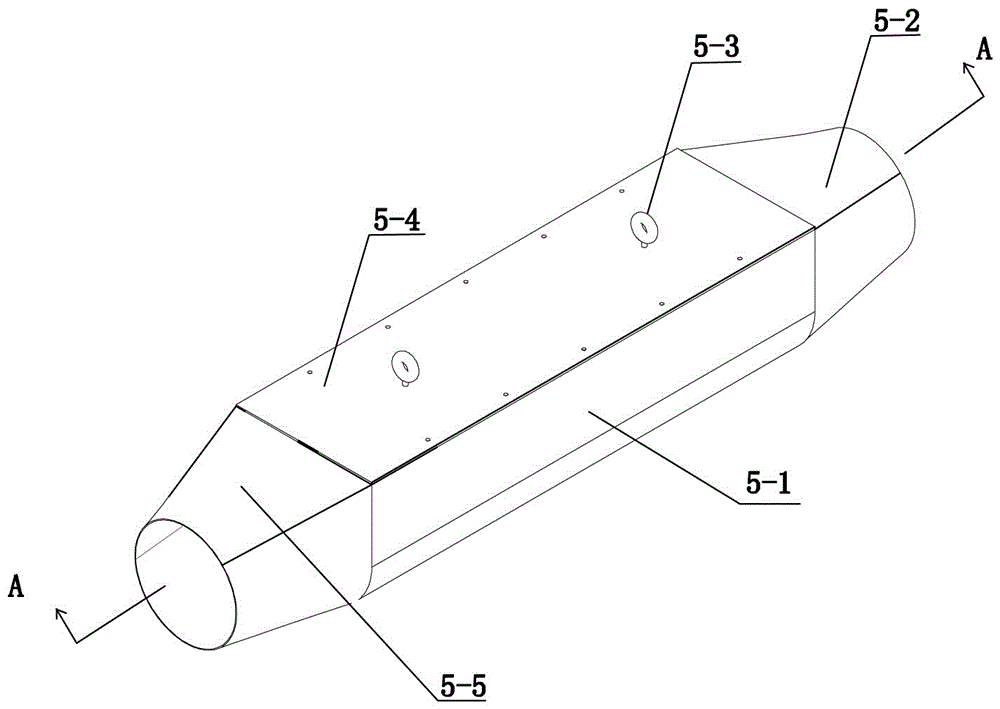

[0026] Such as Figure 1-8 As shown, the mixed flocculation and sedimentation system of the mechanical agitation clarifier of the present invention comprises a main water inlet chute 1, a dosing pipe 2, a water distribution tank 3 connected to the water inlet chute 1, and a water distribution tank 3 connected to the raw water delivery pipeline 4 A connected mechanically stirred clarifier, the mechanically stirred clarifier is mainly composed of a water collection tank 8, a support bridge, a structure wall 10, a driving device, a mechanically stirred clarifier water inlet 7, a mixer 12 with a stirring impeller, and a first reaction chamber 13. The umbrella cover 15 arranged on the first reaction chamber 13, the second reaction chamber 11, the diversion chamber 9 arranged outside the second reaction chamber 11, the separation chamber 6 and the top supporting steel structure c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com