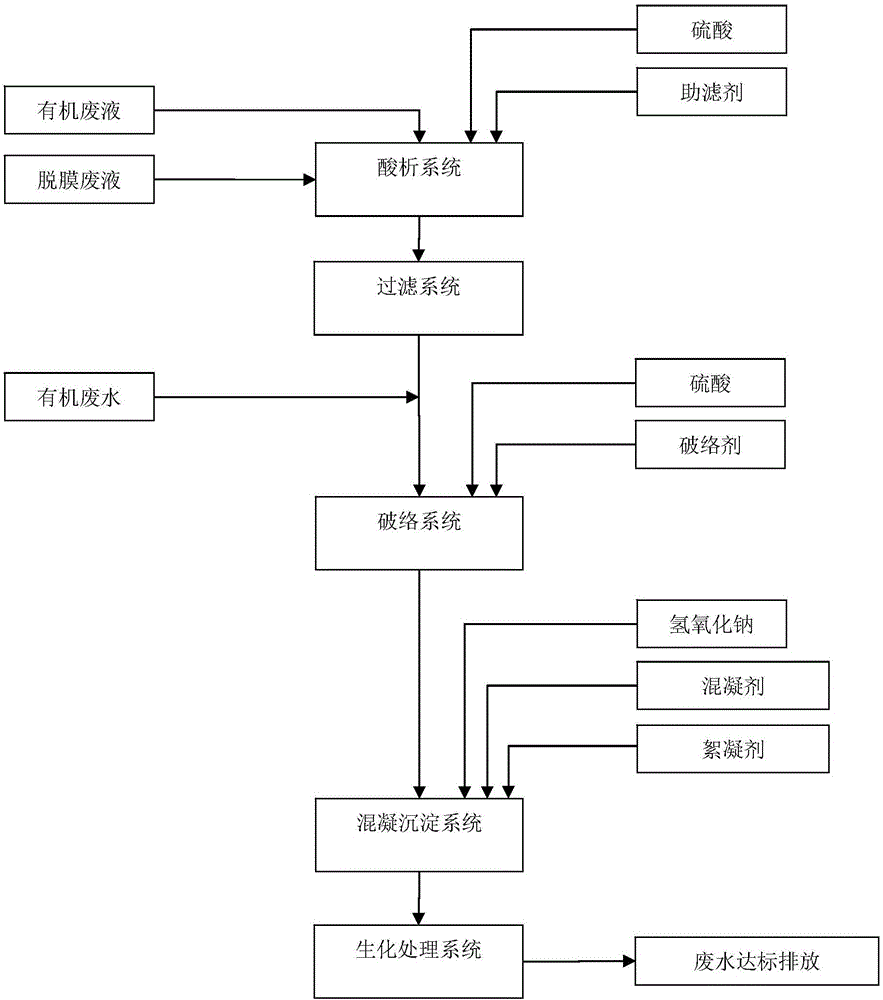

Organic waste liquid treatment process

A technology of organic waste liquid and treatment process, which is applied in the direction of filtration treatment, water/sewage treatment, biological water/sewage treatment, etc., which can solve the problems of high cost, complicated operation and complex composition, and achieve low investment, simple operation and low cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Adopting the organic waste liquid treatment process of the present invention to process the organic waste liquid of a certain factory comprises the following steps:

[0040] a. Acid analysis treatment: In the pH adjustment tank, mix the organic waste liquid and the stripping waste liquid according to the ratio of organic waste liquid / stripping waste liquid ≤ 1.5%, and add sulfuric acid to adjust the pH to 2-3; mix the two The liquid is transported to the acid analysis tank, and the filter aid ferrous sulfate is added at 1.3~1.6kg / m 3 , stirring for 60 to 120 minutes;

[0041] b. Filtration: transfer the waste liquid treated by acid analysis in step a to the filtration system for filtration, and remove the sediment. At this time, the COD content of the filtrate is ≤3000mg / L;

[0042] c. Broken network treatment: mix the organic waste water with the above-mentioned filtrate in the wastewater regulating tank, the mixing amount of the filtrate is ≤15%, add the mixed solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com