Pro-environment hollow brick with plant fiber

A plant fiber and hollow brick technology, which is applied in the field of hollow bricks, can solve the problems of high cost, incompatibility with resource saving, incompatibility, etc., and achieves the effects of low production cost, good seismic effect and energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

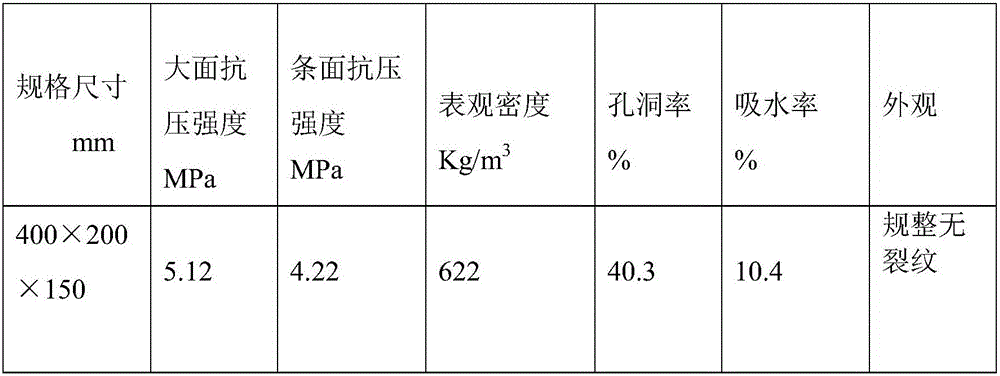

Image

Examples

Embodiment Construction

[0013] An environmentally friendly hollow brick doped with plant fibers, which consists of the following components in parts by weight: 48 parts of coal gangue powder particles, 10 parts of light tailing perlite, 9 parts of cement, 7 parts of boiler slag, and 5 parts of red mud 4 parts of fruit shell slag, 4 parts of grain crop straw, 0.4 part of aluminum powder, 5 parts of epoxy resin, 1.5 parts of plaster powder, 0.6 part of curing agent, 1.5 parts of foam stabilizer, 3 parts of carboxymethyl cellulose , 55 parts of water; Its preparation method comprises the steps:

[0014] (1) Grind coal gangue powder particles, light tailing perlite, and boiler slag to 65 mesh, add appropriate amount of water, curing agent, foam stabilizer, and carboxymethyl cellulose to the mixer, and use a three-stage stirring method , the first stage uses a twin-shaft mixer, and the stirring time is 25 minutes; the second stage uses a wheel mill mixer, and the stirring time is 15 minutes; the third sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com