Warm mix agent for warm mix asphalt and its application method

A technology of warm mix asphalt and application method, which is applied in the field of warm mix agent for warm mix asphalt, can solve the problems of poor low temperature ductility of warm mix asphalt, and achieve the goal of improving the low temperature performance of asphalt, overcoming low temperature ductility difference, and overcoming environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

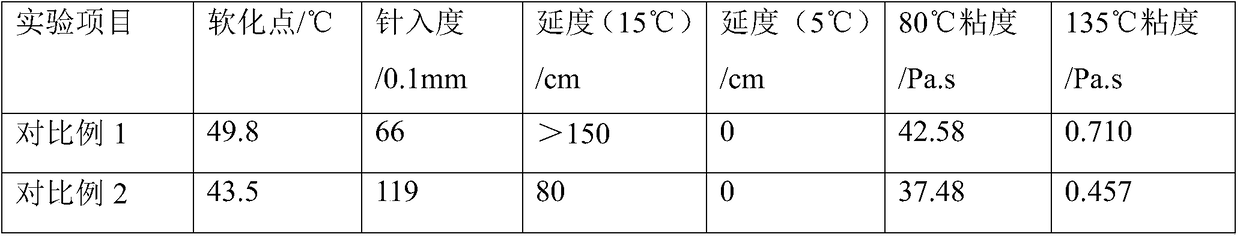

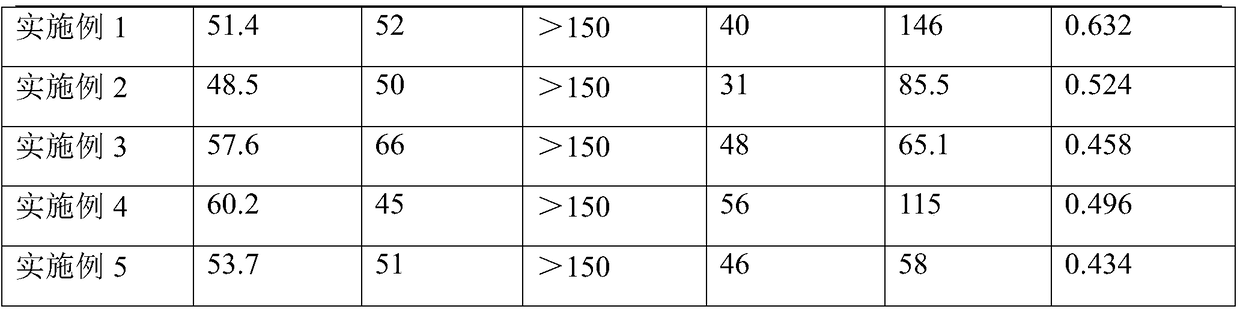

Examples

Embodiment 1

[0028] The warm mix agent for warm mix asphalt consists of the following raw materials in parts by mass:

[0029] 1 part of stearic acid, 1 part of ethylene bis stearamide and 1.5 parts of styrene-butadiene rubber powder.

[0030] The application method of the warm mix agent for warm mix asphalt:

[0031] Heat 70# heavy traffic asphalt to 130°C, add 3wt.% of the above-mentioned warm mixing agent for 70# heavy traffic asphalt, and stir at a constant temperature of 160°C for 20 minutes.

Embodiment 2

[0033] The warm mix agent for warm mix asphalt consists of the following raw materials in parts by mass:

[0034] 1 part of palmitic acid, 2 parts of ethylene bisoleic acid amide and 1 part of styrene-butadiene rubber powder.

[0035] The application method of the warm mix agent for warm mix asphalt:

[0036] Heat 70# heavy-duty asphalt to 135°C, add 70# heavy-duty asphalt with an amount of 1wt.% of the above-mentioned warm mix agent, and stir at a constant temperature of 150°C for 15 minutes.

Embodiment 3

[0038] The warm mix agent for warm mix asphalt consists of the following raw materials in parts by mass:

[0039] 3 parts of stearic acid, 0.5 parts of ethylene bis stearamide and 2 parts of styrene-butadiene rubber powder.

[0040] The application method of the warm mix agent for warm mix asphalt:

[0041] Heat 70# heavy-duty asphalt to 138°C, add 70# heavy-duty asphalt with an amount of 1wt.% of the above-mentioned warm mix agent, and stir at a constant temperature of 155°C for 20 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com