Cationic type gelled acid thickener and preparation method thereof

A cationic, gelled acid technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of inability to meet the requirements of high-temperature deep well acidizing fracturing, low efficiency of residual acid flowback, poor temperature resistance, etc. problems, to achieve the effects of high residual acid flowback efficiency, short swelling time, and good temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1: Preparation of gelled acid thickener.

[0042] (1) Add 20% acrylamide, 1% methyltriphenylphosphine bromide, 1% dimethyl diallyl ammonium chloride, 1% 2-acrylamide to a certain amount of deionized water Base-2-methylpropanesulfonic acid, 0.01% ethylenediaminetetraacetic acid disodium salt and 0.05% urea were stirred evenly and filled with nitrogen for 20 minutes to prepare a comonomer mixture.

[0043] (2) Add 0.01% of the total mass of azobisisobutylamidine hydrochloride and 0.01% of the total mass of sodium bisulfite to the above-mentioned comonomer mixture for initiation, control the reaction temperature at 5° C., and react for 1 hour. Then the reaction container was transferred to a temperature-controlled environment of 40° C., and reacted for 2 hours to obtain a gel-like cationic gelling acid thickener.

[0044] (3) The gelled acid thickener is granulated, dried, pulverized and sieved to obtain dry cationic gelled acid thickener granules.

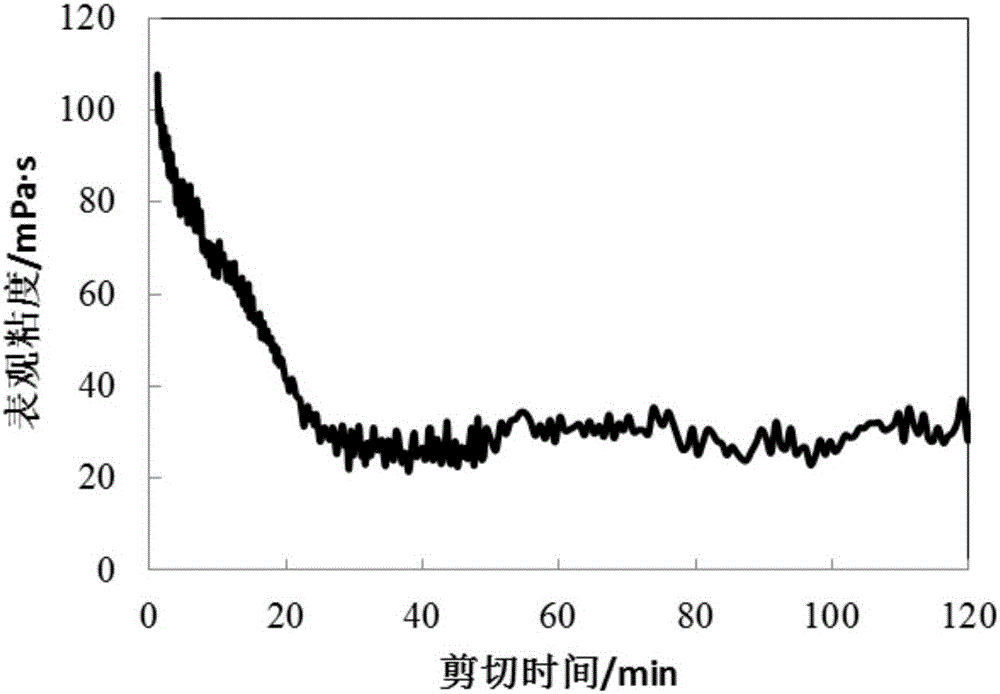

[0045] Af...

Embodiment 2

[0048] Embodiment 2: Preparation of gelled acid thickener.

[0049] (1) Add 25% acrylamide, 2% ethyltriphenylphosphine bromide, 2% dimethyl diallyl ammonium chloride, 2% 2-acrylamide to a certain amount of deionized water Base-2-methylpropanesulfonic acid, 0.05% ethylenediaminetetraacetic acid disodium salt and 0.06% urea were stirred evenly, and after being filled with nitrogen for 20 minutes, a comonomer mixture was obtained.

[0050] (2) Add 0.02% of the total mass of azobisisobutylimidazoline hydrochloride and 0.02% of the total mass of sodium bisulfite to the above-mentioned comonomer mixture for initiation, control the reaction temperature at 15°C, and react for 2 hours . Then the reaction container was transferred to a temperature-controlled environment of 50° C., and reacted for 2 hours to obtain a gel-like cationic gelling acid thickener.

[0051] (3) The gelled acid thickener is granulated, dried, pulverized and sieved to obtain dry cationic gelled acid thickener g...

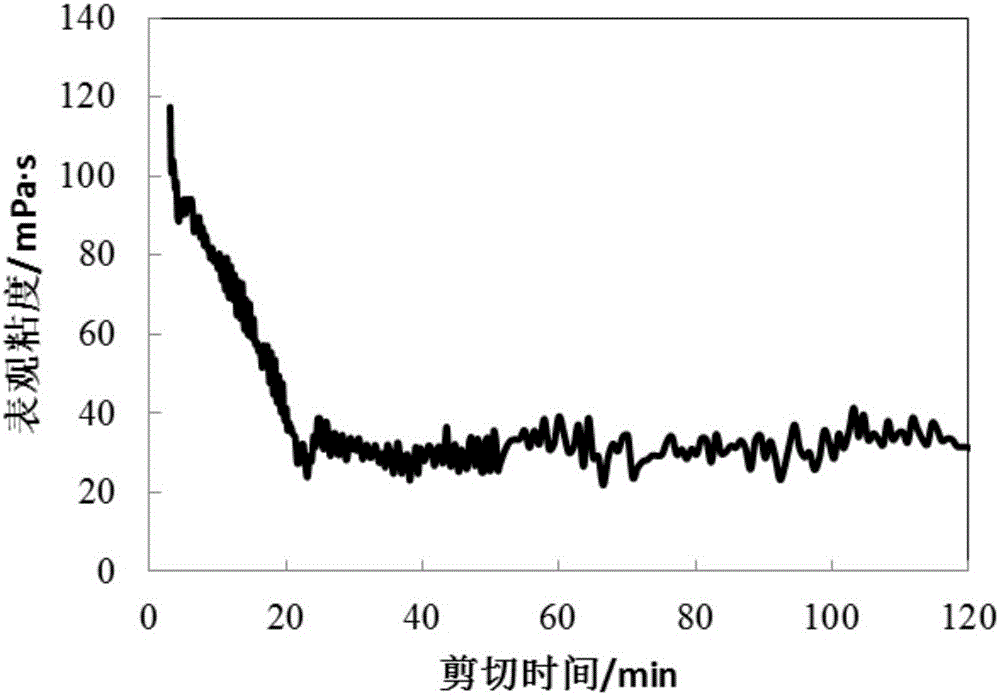

Embodiment 3

[0055] Embodiment 3: Preparation of gelled acid thickener.

[0056] (1) Add 30% acrylamide, 3% allyl triphenylphosphine bromide, 3% dimethyl diallyl ammonium chloride, 3% 2-propene to a certain amount of deionized water Amido-2-methylpropanesulfonic acid, 0.08% ethylenediaminetetraacetic acid disodium salt and 0.08% urea were stirred evenly, and after being filled with nitrogen for 20 minutes, a comonomer mixture was prepared.

[0057] (2) Add 0.03% of the total mass of azobisisobutylamidine hydrochloride and 0.03% of the total mass of sodium sulfite to the above-mentioned comonomer mixture for initiation, control the reaction temperature at 20° C., and react for 3 hours. Then the reaction container was transferred to a temperature-controlled environment of 60° C., and reacted for 3 hours to obtain a gel-like cationic gelling acid thickener.

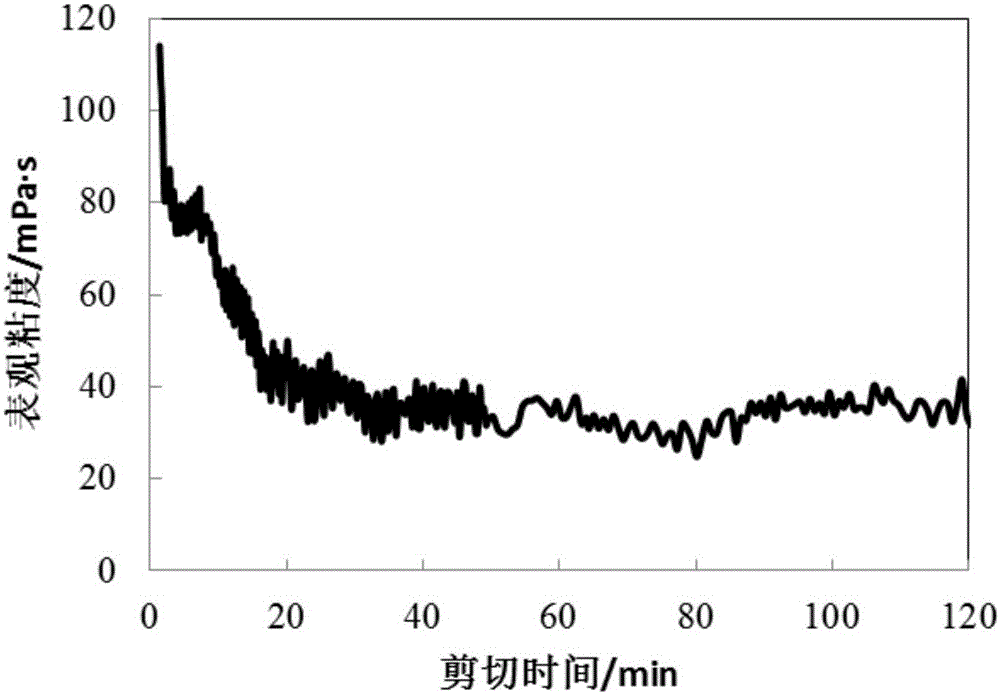

[0058] (3) The cationic gelling acid thickener is granulated, dried, crushed and sieved to obtain dry cationic gelling acid thickener ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com