Hydrophobically associated gelled acid thickening agent and preparation method thereof

A technology of hydrophobic association and gelling acid, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of low residual acid flowback efficiency, long swelling time, poor compatibility, etc., and achieve residual acid flowback. High efficiency, short swelling time and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1: Preparation of gelled acid thickener.

[0049] (1) Add 15% acrylamide, 0.1% cetyldimethylethylammonium bromide, 2% dimethyldiallylammonium chloride, 0.02% ethyl ammonium to a certain amount of deionized water Disodium diamine tetraacetate and 0.02% urea were stirred and dissolved, and nitrogen gas was filled for 30 minutes to prepare a comonomer mixture.

[0050] (2) Add 0.02% of the total mass of azobisisobutylamidine hydrochloride and 0.02% of 2,5-dimethyl-hexyl-(2,5)-bishydroperoxide to the above-mentioned comonomer mixture Initiate with 0.02% sodium bisulfite, the reaction temperature is 70° C., and the reaction time is 3.5 hours to obtain a gel-like thickener.

[0051] (3) The thickener is granulated, dried, pulverized and sieved to obtain dry thickener granules.

[0052] After measurement, the molecular weight of the gelled acid thickener is 4 million, and the particle size of the particles is 50-110 μm.

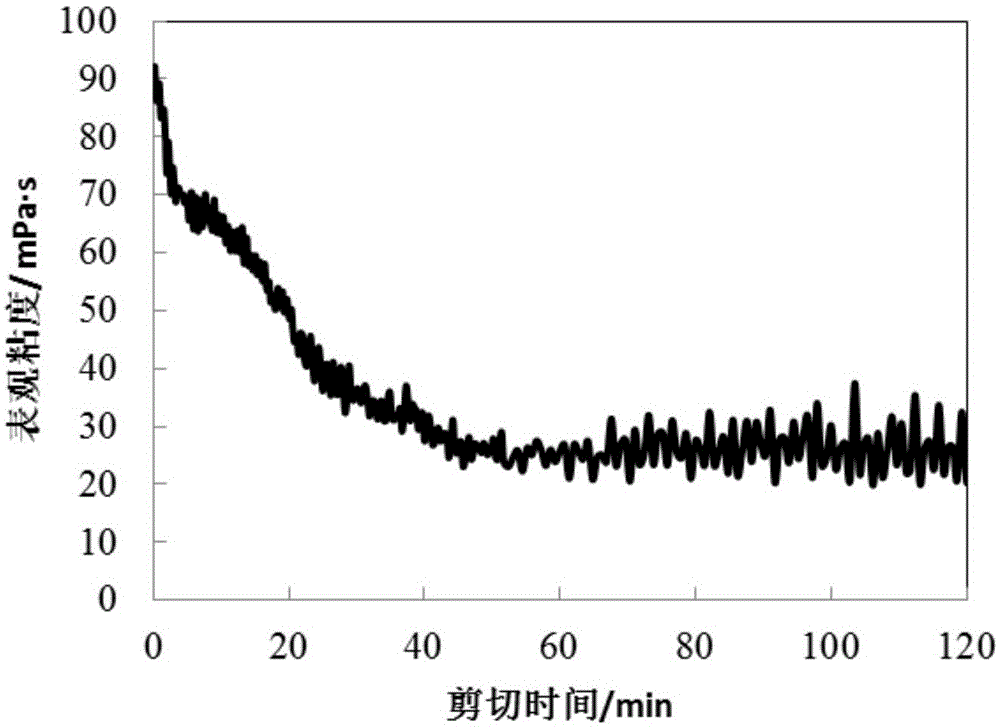

[0053] The rheological curve of gelling aci...

Embodiment 2

[0055] Embodiment 2: Preparation of gelled acid thickener.

[0056] (1) To a certain amount of deionized water, 20% acrylamide, 0.2% cetyl acrylate dimethyl ethyl ammonium bromide, 3% dimethyl diallyl ammonium chloride, 0.03% Disodium edetate and 0.03% urea were stirred and dissolved, and after being filled with nitrogen for 30 minutes, a comonomer mixture was prepared.

[0057] (2) Add 0.03% of the total mass of azobisisobutylamidine hydrochloride and 0.03% of 2,5-dimethyl-hexyl-(2,5)-bishydroperoxide to the above-mentioned comonomer mixture Initiate with 0.03% sodium bisulfite, the reaction temperature is 80° C., and the reaction time is 4 hours to obtain a gel-like thickener.

[0058] (3) The thickener is granulated, dried, pulverized and sieved to obtain dry thickener granules.

[0059] After measurement, the molecular weight of the gelling acid thickener is 5.8 million, and the particle size of the particles is 110-160 μm.

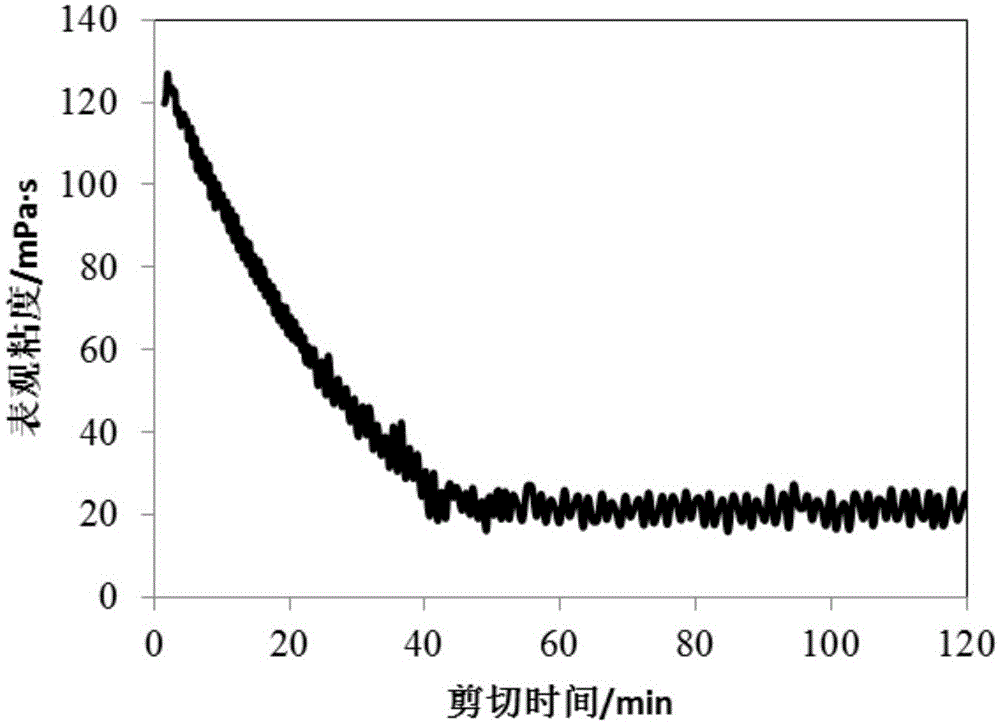

[0060] The rheological curve of gelling acid...

Embodiment 3

[0062] Embodiment 3: Preparation of gelled acid thickener.

[0063] (1) To a certain amount of deionized water, add 25% acrylamide, 0.3% N-hexadecyl acrylamide, 4% N,N-dimethylaminoethyl methacrylate, 0.05% Disodium edetate and 0.05% urea were stirred and dissolved, and after being filled with nitrogen for 30 minutes, a comonomer mixture was obtained.

[0064] (2) Add 0.05% of the total mass of azobisisobutylamidine hydrochloride and 0.05% of 2,5-dimethyl-hexyl-(2,5)-bishydroperoxide to the above-mentioned comonomer mixture Initiate with 0.05% sodium bisulfite, the reaction temperature is 80° C., and the reaction time is 4.5 hours to obtain a gel-like thickener.

[0065] (3) The thickener is granulated, dried, pulverized and sieved to obtain dry thickener granules.

[0066] After measurement, the molecular weight of the gelled acid thickener is 6.9 million, and the particle size is 120-175 μm.

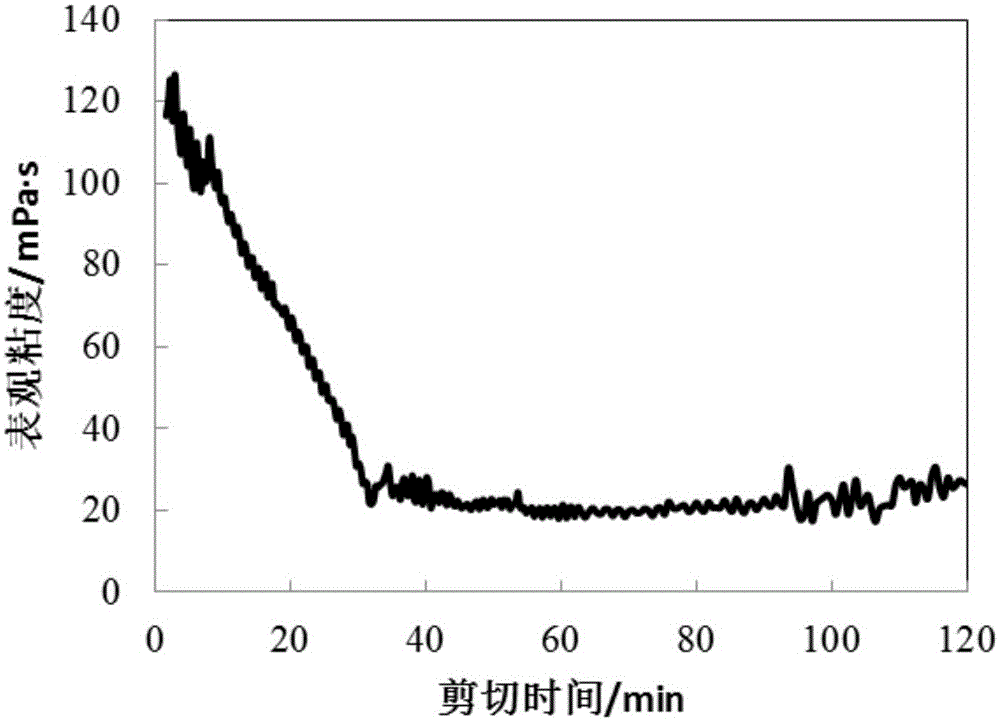

[0067] The rheological curve of gelling acid prepared by dissolving 1% of the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com