A method for removing carbon from copper-containing iron water by eddy current entanglement in limestone

A technology of limestone and molten iron, applied in the field of metallurgy, to achieve the effect of rapid and thorough reaction, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

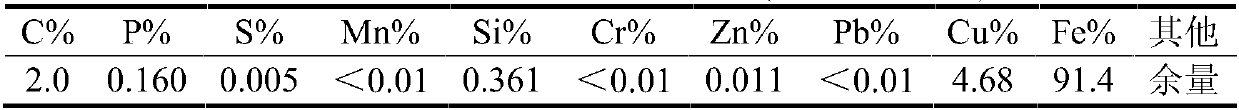

[0041] The specific composition of the copper-containing molten iron used in this example is shown in Table 1.

[0042] Table 1 Contents of each element in copper-containing hot metal (mass fraction, %)

[0043]

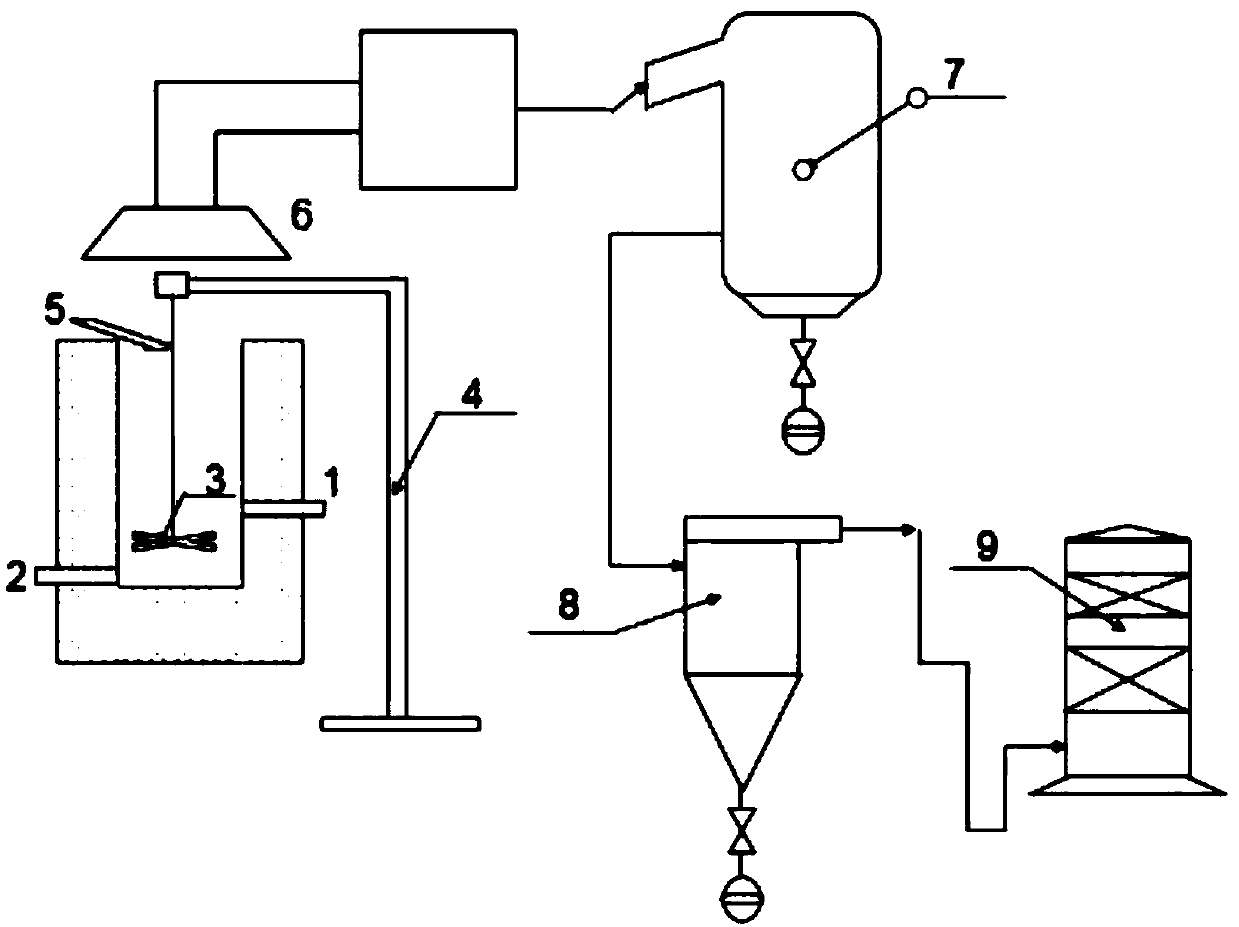

[0044] The structural schematic diagram of the induction furnace system adopted in this embodiment is shown in figure 1 .

[0045] A method for removing carbon from copper-containing hot metal by eddy currents involving limestone, comprising the following steps:

[0046] (1) After taking copper slag and adding a carbonaceous reducing agent, the copper-containing molten iron obtained by reduction has a temperature of 1450°C and a mass of 20t. It is added to an induction furnace, and the temperature of the copper-containing molten iron is controlled to be 1450°C. The mass percentage of C is 2.0%, and the mass percentage of Cu is 4.68%;

[0047] (2) Adjust the stirring paddle 3 to be inserted to 1 / 3 of the height of the liquid level of the copper-containing molten...

Embodiment 2

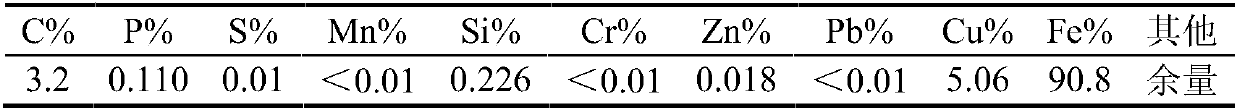

[0053] The specific composition of the copper-containing molten iron used in this example is shown in Table 2.

[0054] Table 2 Contents of each element in copper-containing molten iron (mass fraction, %)

[0055]

[0056] The structural schematic diagram of the induction furnace system adopted in this embodiment is shown in figure 1 .

[0057] A method for removing carbon from copper-containing hot metal by eddy currents involving limestone, comprising the following steps:

[0058] (1) After taking copper slag and adding a carbonaceous reducing agent, the copper-containing molten iron obtained by reduction has a temperature of 1500°C and a mass of 20t. It is added to an induction furnace, and the temperature of the copper-containing molten iron is controlled at 1500°C. The copper-containing molten iron contains The mass percentage of C is 3.2%, and the mass percentage of Cu is 5.06%;

[0059] (2) Adjust the stirring paddle 3 to be inserted to 1 / 3 of the height of the li...

Embodiment 3

[0065] The specific composition of the copper-containing molten iron used in this example is shown in Table 3.

[0066] Table 3 Contents of each element in copper-containing hot metal (mass fraction, %)

[0067]

[0068] The structural schematic diagram of the induction furnace system adopted in this embodiment is shown in figure 1 .

[0069] A method for removing carbon from copper-containing hot metal by eddy currents involving limestone, comprising the following steps:

[0070] (1) After taking copper slag and adding carbonaceous reducing agent, the copper-containing molten iron obtained by reduction has a temperature of 1550°C and a mass of 30t. It is added to the induction furnace, and the temperature of the copper-containing molten iron is controlled at 1550°C. The copper-containing molten iron contains The mass percentage of C is 4.5%, and the mass percentage of Cu is 5.24%;

[0071] (2) Adjust the stirring paddle 3 to be inserted to 1 / 2 of the height of the coppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com