Vaporization device for liquefied natural gas supply system for automobile

A technology of liquefied natural gas and gas supply system, which is applied in the field of liquefied natural gas vehicle gas system, which can solve problems such as weak pressurization speed, insufficient gas supply, and potential safety hazards, so as to achieve comprehensive and smooth flow, improve heat exchange effect, and ensure normal operation running effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

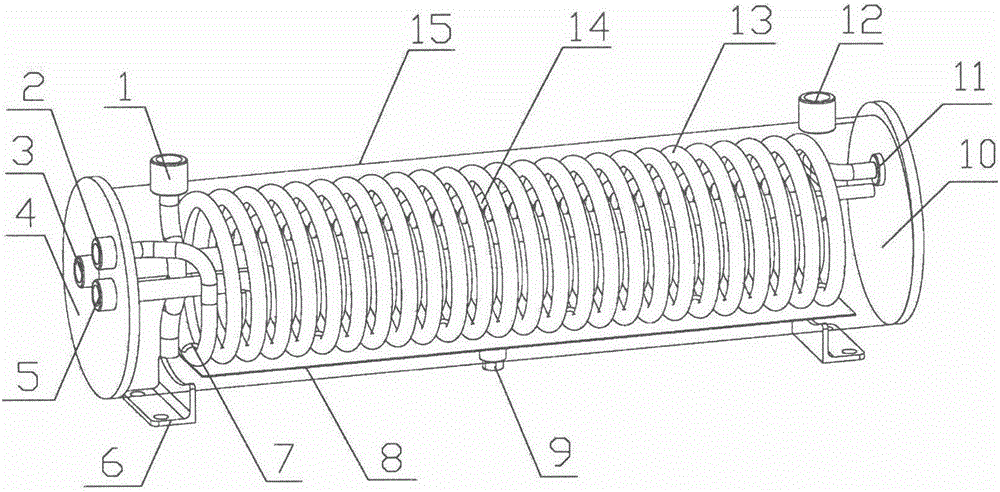

[0024] see figure 1 , figure 1 It is a structural schematic diagram of the vaporization device of the liquefied natural gas gas supply system for automobiles of the present invention. Such as figure 1 As shown, in the vaporization device of the liquefied natural gas gas supply system for automobiles, the cooling assembly, gasification assembly, pressurization assembly and blowdown assembly are all connected to the box body 15, and the gasification assembly and the pressurization assembly are arranged on the box body 15, the cooling assembly is arranged above the box body 15, and the sewage discharge assembly is arranged below the box body 15.

[0025] The box body 15 is a horizontal cylindrical structure, and the two bottom surfaces of the cylindrical structure are the left sealing plate 4 and the right sealing plate 10 of the box body 15 .

[0026] The cooling assembly includes a water inlet 1 and a water return port 12, the water inlet 1 and the water return port 12 are b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com