3D printing PCL/beta-TCP composite material and preparation method, application and printing method thereof

A composite material, 3D printing technology, applied in the fields of additive processing, medical science, tissue regeneration, etc., can solve problems such as reducing negative effects, and achieve the effects of reducing negative effects, avoiding secondary operations, and good biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

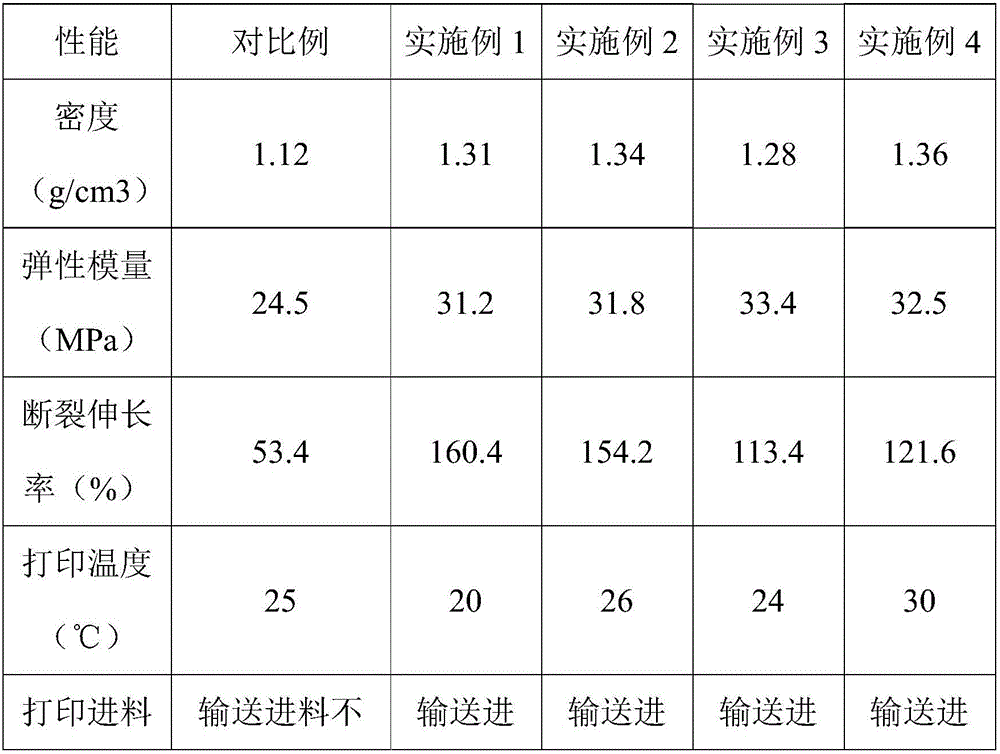

Examples

Embodiment 1

[0042] A 3D printing PCL / β-TCP composite material, the raw material contains the following components by weight percentage:

[0043] Beta-tricalcium phosphate 95%

[0044] Polycaprolactone 5%

[0045] Prepared by:

[0046] (1) Take by weighing β-tricalcium phosphate and polycaprolactone that quality is 9.5g, 0.5g respectively;

[0047] (2) Add β-tricalcium phosphate into 60mL of chloroform, stir and mix in a constant temperature magnetic stirrer at 30°C for 10min, and the stirring speed is 300rpm;

[0048] (3) Add polycaprolactone to the CHCl of the above-mentioned β-tricalcium phosphate 3 In the suspension, continue magnetic stirring at 18°C for 180 minutes to fully dissolve the polycaprolactone;

[0049] (4) Adjust the temperature of the constant temperature magnetic stirrer to 60°C, continue magnetic stirring for 180min, and make CHCl 3The composite material is obtained by rapid evaporation.

Embodiment 2

[0051] A 3D printing PCL / β-TCP composite material, the raw material contains the following components by weight percentage:

[0052] Beta-tricalcium phosphate 40%

[0053] Polycaprolactone 60%

[0054] Prepared by:

[0055] (1) Take by weighing β-tricalcium phosphate and polycaprolactone that quality is 4.0g, 6.0g respectively;

[0056] (2) Add β-tricalcium phosphate into 40mL of chloroform, stir and mix in a constant temperature magnetic stirrer at 18°C for 30min, and the stirring speed is 800rpm;

[0057] (3) Add polycaprolactone to the CHCl of the above-mentioned β-tricalcium phosphate 3 In the suspension, continue magnetic stirring at 30°C for 60 minutes to fully dissolve the polycaprolactone;

[0058] (4) Adjust the temperature of the constant temperature magnetic stirrer to 40°C, continue magnetic stirring for 40min, and make CHCl 3 The composite material is obtained by rapid evaporation.

Embodiment 3

[0060] A 3D printing PCL / β-TCP composite material, the raw material mainly contains the following components by weight percentage:

[0061] Beta-tricalcium phosphate 45%

[0062] Polycaprolactone 55%

[0063] Prepared by:

[0064] (1) Take by weighing β-tricalcium phosphate and polycaprolactone that quality is 4.5g, 5.5g respectively;

[0065] (2) Add β-tricalcium phosphate into 60mL of chloroform, stir and mix in a constant temperature magnetic stirrer at 20°C for 5min, and the stirring speed is 500rpm;

[0066] (3) Add polycaprolactone to the CHCl of the above-mentioned β-tricalcium phosphate 3 In the suspension, continue magnetic stirring at 25°C for 30 minutes to fully dissolve the polycaprolactone;

[0067] (4) Adjust the temperature of the constant temperature magnetic stirrer to 70°C, continue magnetic stirring for 100min, and make CHCl 3 The composite material is obtained by rapid evaporation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com