Composite hydrogel bracket, and preparation method and application thereof

A composite hydrogel and gel technology, applied in the medical field, can solve problems such as harmful to the human body, difficult to remove, and poor biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

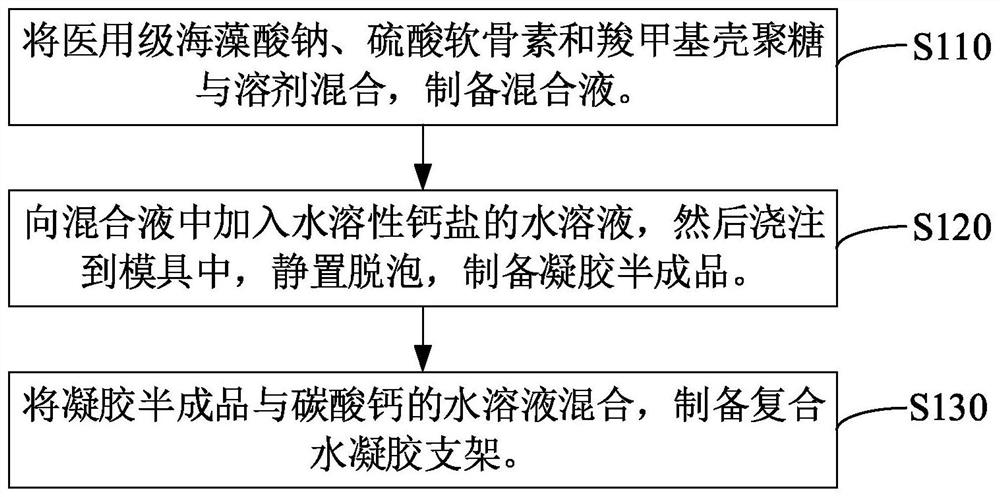

[0032] see figure 1 , the preparation method of the composite hydrogel scaffold of one embodiment, comprises the steps:

[0033] Step S110 : mixing medical grade sodium alginate, chondroitin sulfate, and carboxymethyl chitosan with the diluent to prepare a mixed solution.

[0034] Among them, alginic acid is a natural polyanionic polysaccharide, the most common of which is sodium alginate. Sodium alginate is widely used in the fields of food, medicine and tissue engineering due to its good biocompatibility, safety, non-toxicity, low cost and easy availability. Due to its good gel-forming properties and biological properties, it has become a common material for preparing hydrogels, and can usually be used as immobilization and embedding carriers for enzymes, proteins, animal and plant cells, and the like. In addition, alginate forms an open-lattice hydrogel through cross-linking in the presence of calcium ions, and the gel's lattice provides support for cells. Arranged growt...

Embodiment 1

[0062] The preparation process of the composite hydrogel scaffold of the present embodiment is as follows:

[0063] (1) Fully mix chondroitin sulfate A, medical grade sodium alginate (G / M is 45 / 55, viscosity is 400mpa.s) and carboxymethyl chitosan powder to obtain mixed raw materials, and then add phosphate buffer (pH 7.4), prepare the mixed solution. In the mixture, the mass fraction of chondroitin sulfate A is 1%, the mass fraction of medical grade sodium alginate is 4%, and the mass fraction of carboxymethyl chitosan is 2%.

[0064] (2) Put the mixed solution obtained in step (1) into a magnetic stirring water bath with a temperature of 60° C. and stir, and the stirring speed is 600 rpm / min, so that the mixed solution is fully mixed.

[0065] (3) Putting the homogeneously dissolved mixed solution obtained in step (2) into ultrasonic for defoaming treatment.

[0066] (4) Slowly adding a calcium chloride aqueous solution with a volume ratio of 1:10 to the defoamed mixed sol...

Embodiment 2

[0071] The preparation process of the composite hydrogel scaffold of the present embodiment is as follows:

[0072] (1) Fully mix chondroitin sulfate A, medical grade sodium alginate (G / M is 55 / 45, viscosity is 550mpa.s) and carboxymethyl chitosan powder to obtain mixed raw materials, and then add phosphate buffer (pH 7.4), prepare the mixed solution. In the mixture, the mass fraction of chondroitin sulfate A is 1.5%, the mass fraction of medical grade sodium alginate is 7%, and the mass fraction of carboxymethyl chitosan is 4%.

[0073] (2) Put the mixed solution obtained in step (1) into a magnetic stirring water bath with a temperature of 50° C. and stir, and the stirring speed is 500 rpm / min, so that the mixed solution is fully mixed.

[0074] (3) Putting the homogeneously dissolved mixed solution obtained in step (2) into ultrasonic for defoaming treatment.

[0075] (4) Slowly add a calcium chloride aqueous solution with a volume ratio of 1:8 to the defoamed mixed solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com