Material distributing equipment for whole body marble and production technology for whole body marble

A production process, marble technology, applied in auxiliary molding equipment, manufacturing tools, supply devices, etc., can solve the problems of low utilization rate of powder and equipment, unusable remaining toner, and difficulty in changing production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

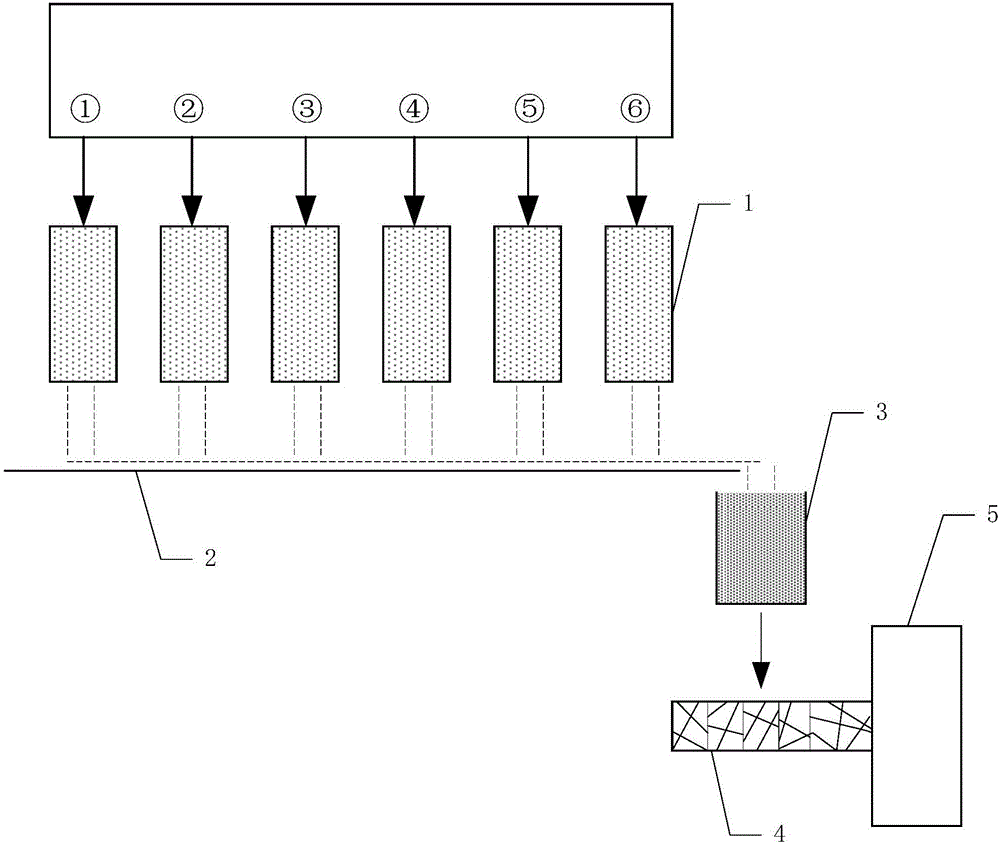

[0068] A kind of production technology of whole body marble comprises the following steps:

[0069] A. Take the raw materials, formulate into a formula with a whiteness of 35°-38°, put it into a ball mill, and ball-mill it into a slurry. The moisture content of the slurry is 30-35%. After passing through a 250-mesh sieve, the sieve residue is between 0.3-0.8 ;

[0070] B. Atomized and drained to obtain powder, the moisture content of the powder is 5-7%, and it is sent to the powder bin to stale;

[0071] C. Take the color material from the discharge port of the powder transfer hopper, adjust the ratio of each color material according to each layout, and send it to the press after grid embossing, and press it into shape, with a pressure of 30000-34000KN;

[0072] D. Drying, glazing, inkjet, and glazing of the molding materials;

[0073] Among them, the drying temperature is 200°C, and the water content of the dried material is less than 0.5%; the method of inkjet is: one of t...

Embodiment 1

[0090] Whole body marble production process, including steps:

[0091] A1. The raw materials are formulated into a formula with a whiteness of 38°, ball milled into a slurry, the slurry moisture is maintained at 32%, and the sieve is passed through a 250-mesh sieve, and the sieve residue is about 0.5.

[0092] B1. Atomized and drained to obtain powder, the moisture content of the powder is 6%, and it is sent to the powder bin to stale.

[0093] C1. Take out the powder, use the whole body marble distributing equipment, pass the toner of different colors through the color hopper, fall on the fabric belt, and transport it to the powder transfer hopper by the fabric belt, and then transfer the toner to the powder transfer hopper Clothed into the grid, the grid is sent into the mold cavity for compression molding, and the whole body marble made can maintain the same texture and basically the same color; among them, the compression molding pressure is 32000KN.

[0094] D1. Accordin...

Embodiment 2

[0097] Whole body marble production process, including steps:

[0098] A2. The raw materials are formulated into a formula with a whiteness of 35°, ball milled into a slurry, the slurry moisture is maintained at 32%, and the sieve is passed through a 250-mesh sieve, and the sieve residue is about 0.5.

[0099] B2. Atomized and drained to obtain powder, the moisture content of which is 6%, and sent to the powder bin to stale.

[0100] C2. Take out the powder, use the whole body marble distributing equipment, pass the toner of different colors through the color hopper, fall onto the fabric belt, and transport it to the powder transfer hopper by the fabric belt, and then transfer the toner from the powder transfer hopper Clothed into the grid, the grid is fed into the mold cavity for compression molding, and the whole body marble can maintain the same texture and basically the same color; the compression molding pressure is 30000KN.

[0101] D2. Follow the steps of pressing and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com