A kind of epoxy resin material with low thermal expansion at room temperature and preparation method thereof

A technology of epoxy resin and low thermal expansion, which is applied in the field of room temperature low thermal expansion epoxy resin material and its preparation, can solve the problems of poor shear strength, large internal stress, high crosslinking density, etc., and achieve improved thermal conductivity, dielectric The effect of performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

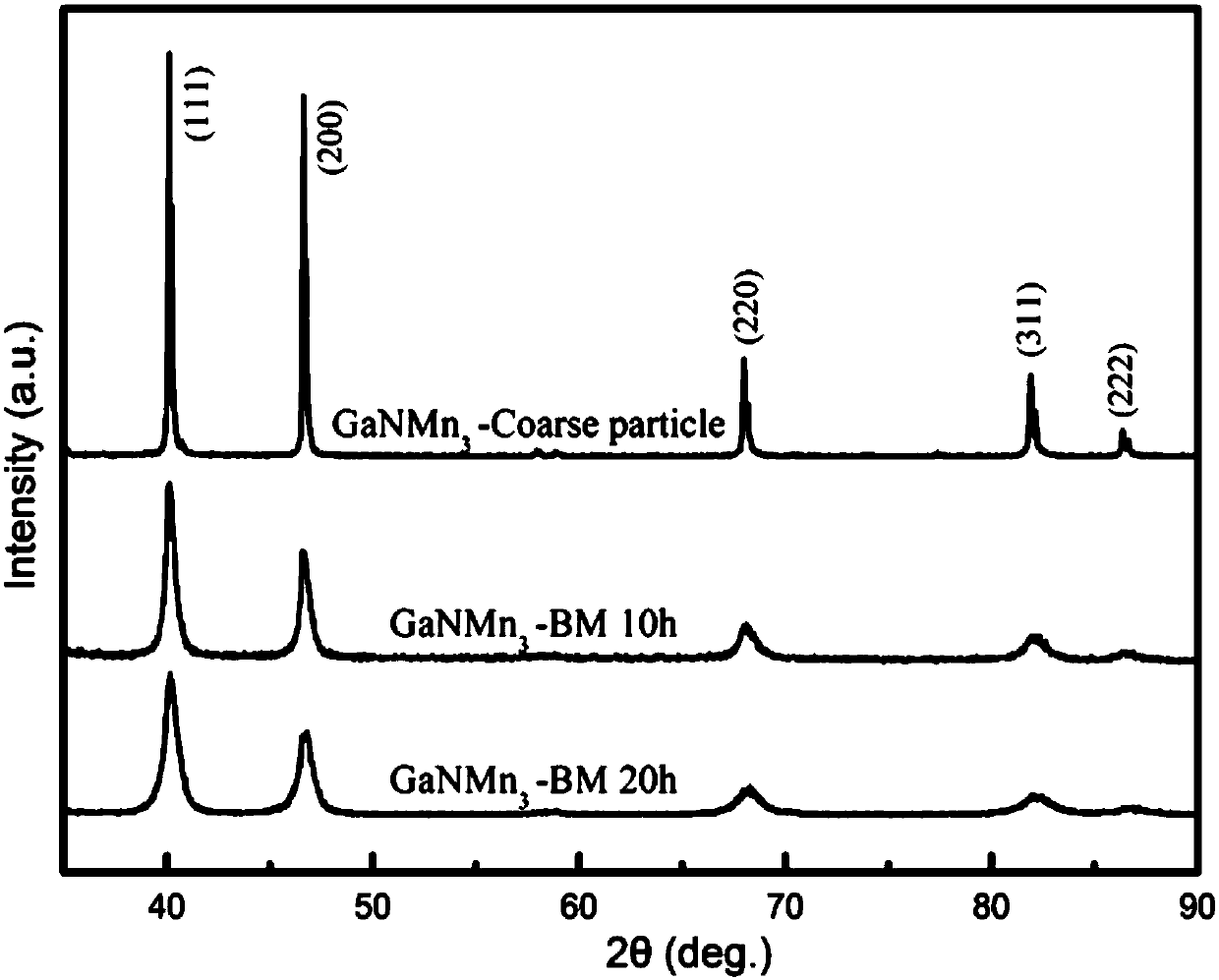

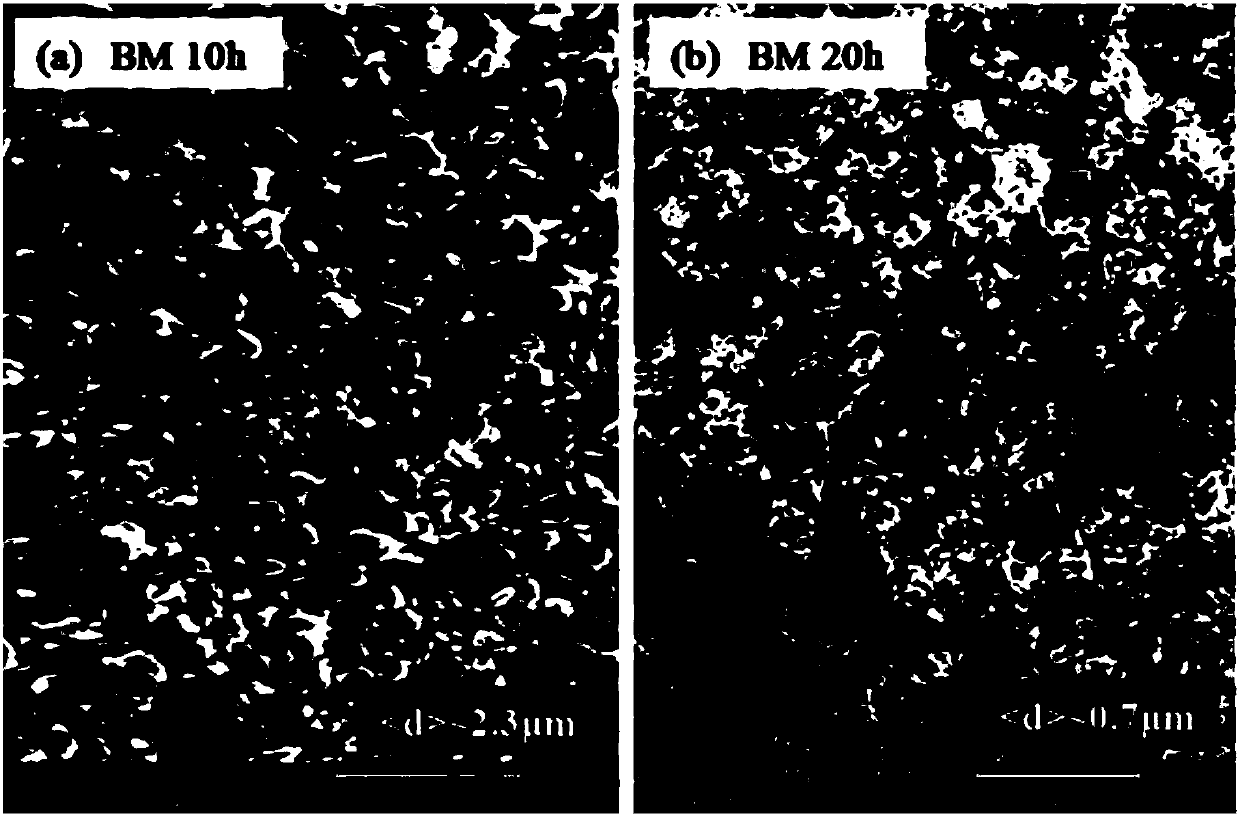

[0029] The present invention also proposes a method for preparing an epoxy resin material with low thermal expansion at room temperature, which includes the following steps: heating the epoxy resin to 90°C, keeping it warm for 10 minutes, adding GaNMn with a particle size of 2.3 μm 3 Stir the micro-nano powder evenly, epoxy resin and GaNMn with a particle size of 2.3 μm 3 The volume ratio of the micro-nano powder is 62:38. Vacuum debubbles for 0.5h. During the process of vacuum debubbling, maintain the temperature at 90°C. Then add 4,4'-diaminodiphenylsulfone, raise the temperature to 120°C, and stir for 2h. Vacuum debubbles for 0.5h, maintain the temperature at 120°C during the process of vacuum debubbling, then solidify, and naturally cool to room temperature to obtain a room temperature low thermal expansion epoxy resin material.

Embodiment 2

[0031] The present invention also proposes a method for preparing an epoxy resin material with low thermal expansion at room temperature, which includes the following steps: heating the epoxy resin to 90°C, keeping it warm for 10 minutes, adding GaNMn with a particle size of 2.3 μm 3 Stir the micro-nano powder evenly, epoxy resin and GaNMn with a particle size of 2.3 μm 3 The volume ratio of the micro-nano powder is 41:59. Vacuum debubbles for 0.5h. During the process of vacuum debubbling, maintain the temperature at 90°C. Then add 4,4'-diaminodiphenylsulfone, raise the temperature to 120°C, and stir for 2h. Vacuum debubbles for 0.5h, maintain the temperature at 120°C during the process of vacuum debubbling, then solidify, and naturally cool to room temperature to obtain a room temperature low thermal expansion epoxy resin material.

Embodiment 3

[0033] The present invention also proposes a method for preparing an epoxy resin material with low thermal expansion at room temperature, which includes the following steps: heating the epoxy resin to 90°C, keeping it warm for 10 minutes, adding GaNMn with a particle size of 2.3 μm3 Stir the micro-nano powder evenly, epoxy resin and GaNMn with a particle size of 2.3 μm 3 The volume ratio of the micro-nano powder is 33:67. Vacuum debubbles for 0.5h. During the process of vacuum debubbling, maintain the temperature at 90°C. Then add 4,4'-diaminodiphenylsulfone, raise the temperature to 120°C, and stir for 2h. Vacuum debubbles for 0.5h, maintain the temperature at 120°C during the process of vacuum debubbling, then solidify, and naturally cool to room temperature to obtain a room temperature low thermal expansion epoxy resin material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com